2月 . 13, 2025 00:06

Back to list

perforated metal sheet

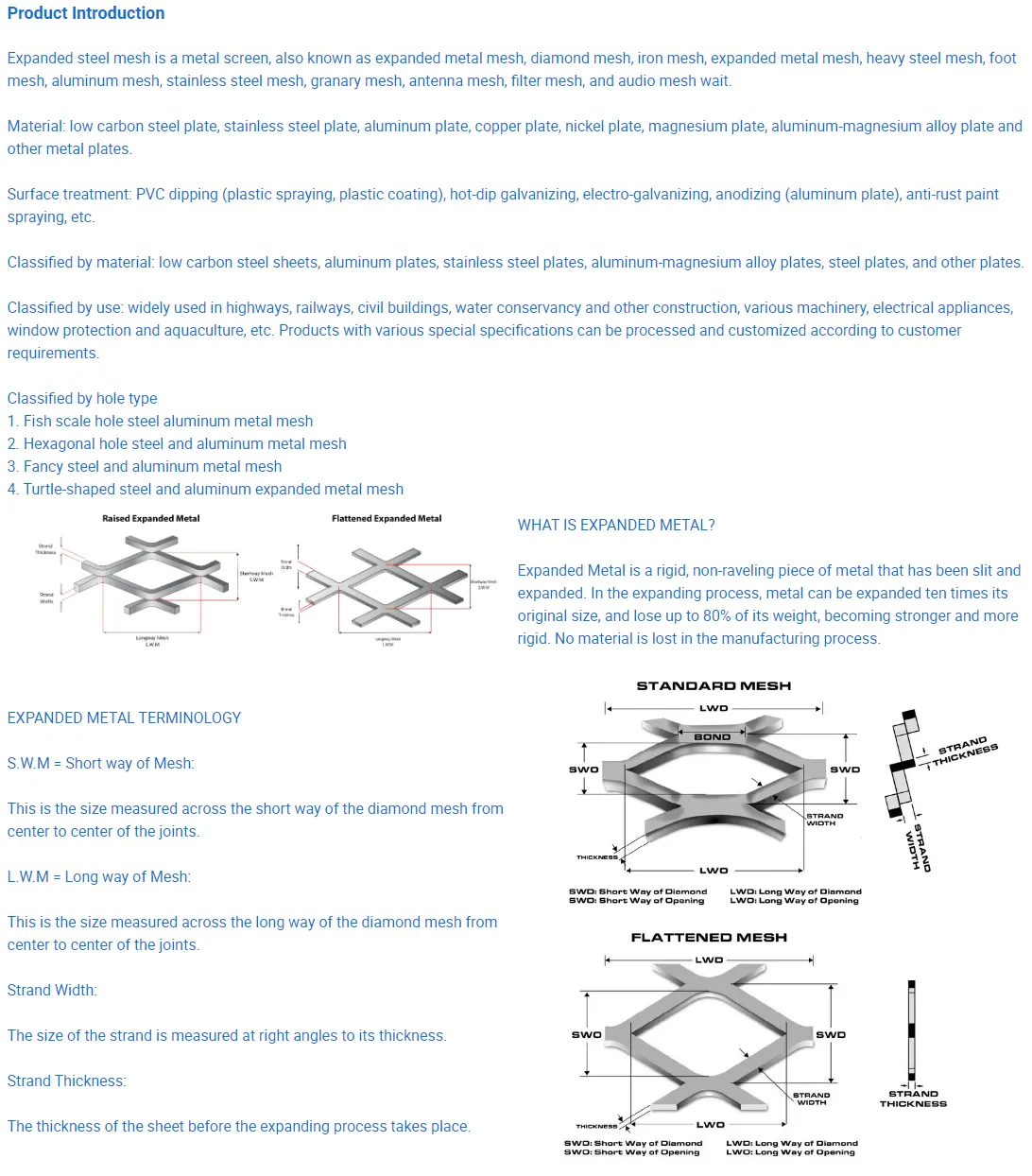

Hexagonal perforated sheets have increasingly become the go-to choice in a variety of industries, offering a unique combination of strength, versatility, and aesthetic appeal. With an impressive history of application in areas ranging from architecture to industrial manufacturing, these sheets are lauded for their distinctive honeycomb pattern. This structure not only provides an appealing visual but also enhances the material's overall functionality.

Incorporating hexagonal perforated sheets into your design or manufacturing process not only enhances functional efficiency but also adds an element of quality and resilience. Their multipurpose nature is evidenced by their growing use in both the commercial and art sectors—employed in creating acoustically optimized environments, enhancing sound quality and absorption in auditoriums and theaters without sacrificing visual appeal. Furthermore, these sheets are subjected to rigorous testing and quality control measures to ensure they meet industry standards. Their quality is backed by a wealth of expert knowledge and experience in fabrication and application, highlighting their reliability. Companies specializing in these products often provide detailed technical support and consultation to guide clients in selecting the appropriate material and pattern specifications for their unique needs. Emphasizing expertise, the production of hexagonal perforated sheets involves advanced techniques and precise engineering. These sheets are tailored to exact specifications, allowing for custom sizes and perforation patterns to suit specific applications. This precision in manufacturing guarantees that each product not only meets but exceeds anticipated performance benchmarks. Trust in hexagonal perforated sheets is built on their proven track record of reliability and efficiency across diverse applications. Their usage within critical infrastructures highlights their importance in both safety and operational success. This reliability translates into fewer maintenance demands and longer service life, offering an economical solution to businesses looking for long-term benefits. In conclusion, the advantages of using hexagonal perforated sheets are manifold. Their blend of aesthetic value, functionality, and robust performance across various sectors underscores their position as a premier solution in modern design and engineering. Investing in these sheets means investing in quality, durability, and innovative design—qualities that resonate with businesses and industries aiming for sustainable and cutting-edge solutions.

Incorporating hexagonal perforated sheets into your design or manufacturing process not only enhances functional efficiency but also adds an element of quality and resilience. Their multipurpose nature is evidenced by their growing use in both the commercial and art sectors—employed in creating acoustically optimized environments, enhancing sound quality and absorption in auditoriums and theaters without sacrificing visual appeal. Furthermore, these sheets are subjected to rigorous testing and quality control measures to ensure they meet industry standards. Their quality is backed by a wealth of expert knowledge and experience in fabrication and application, highlighting their reliability. Companies specializing in these products often provide detailed technical support and consultation to guide clients in selecting the appropriate material and pattern specifications for their unique needs. Emphasizing expertise, the production of hexagonal perforated sheets involves advanced techniques and precise engineering. These sheets are tailored to exact specifications, allowing for custom sizes and perforation patterns to suit specific applications. This precision in manufacturing guarantees that each product not only meets but exceeds anticipated performance benchmarks. Trust in hexagonal perforated sheets is built on their proven track record of reliability and efficiency across diverse applications. Their usage within critical infrastructures highlights their importance in both safety and operational success. This reliability translates into fewer maintenance demands and longer service life, offering an economical solution to businesses looking for long-term benefits. In conclusion, the advantages of using hexagonal perforated sheets are manifold. Their blend of aesthetic value, functionality, and robust performance across various sectors underscores their position as a premier solution in modern design and engineering. Investing in these sheets means investing in quality, durability, and innovative design—qualities that resonate with businesses and industries aiming for sustainable and cutting-edge solutions.

Latest news

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP