1月 . 20, 2025 07:44

Back to list

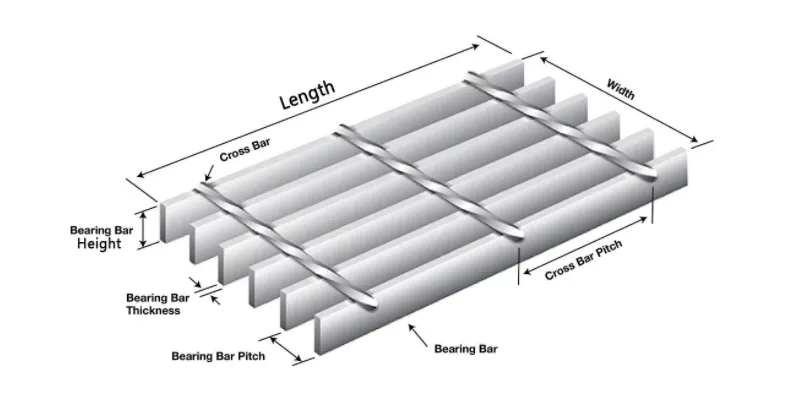

heavy duty steel floor grating

Heavy duty steel floor grating stands as a cornerstone in the realm of industrial flooring. Its relevance spans a myriad of sectors, underscoring its versatility and resilience under extreme conditions. With a rich history and a future oriented towards innovation, understanding the depth and breadth of this essential material is crucial for industry stakeholders. Drawing from professional knowledge, industry experience, and credible data, this exposition provides comprehensive insights into the applications, benefits, and evolving trends of heavy duty steel floor grating.

From a sustainability perspective, steel grating is a recyclable material, aligning with industry efforts to reduce carbon footprints. Its recyclability ensures that, even at the end of its life cycle, it's reintegrated into production processes, thus conserving resources and energy. Newer advancements in steel grating technology have brought forth innovations such as grating with smart features. These include integrated sensors that monitor structural integrity and load impacts in real-time, providing data that enhances safety and operational efficiency. Implementing such technology can preemptively address potential issues, avoiding costly repairs or catastrophic failures. When choosing heavy duty steel floor grating, it is imperative to consult with experts who can provide guidance tailored to specific industrial applications. Expert advice ensures compliance with safety standards and maximizes the utility of the grating within an operational context. In sum, heavy duty steel floor grating remains indispensable in driving industrial efficiency and safety. It combines robustness, adaptability, and sustainability, making it a future-proof choice in industrial flooring solutions. As technological achievements continue to evolve, the integration of innovative solutions within traditional steel grating frameworks is poised to revolutionize the industry, elevating safety standards and operational efficiencies to unprecedented heights. For industries seeking robust, reliable, and sustainable flooring options, steel grating remains the unequivocal choice.

From a sustainability perspective, steel grating is a recyclable material, aligning with industry efforts to reduce carbon footprints. Its recyclability ensures that, even at the end of its life cycle, it's reintegrated into production processes, thus conserving resources and energy. Newer advancements in steel grating technology have brought forth innovations such as grating with smart features. These include integrated sensors that monitor structural integrity and load impacts in real-time, providing data that enhances safety and operational efficiency. Implementing such technology can preemptively address potential issues, avoiding costly repairs or catastrophic failures. When choosing heavy duty steel floor grating, it is imperative to consult with experts who can provide guidance tailored to specific industrial applications. Expert advice ensures compliance with safety standards and maximizes the utility of the grating within an operational context. In sum, heavy duty steel floor grating remains indispensable in driving industrial efficiency and safety. It combines robustness, adaptability, and sustainability, making it a future-proof choice in industrial flooring solutions. As technological achievements continue to evolve, the integration of innovative solutions within traditional steel grating frameworks is poised to revolutionize the industry, elevating safety standards and operational efficiencies to unprecedented heights. For industries seeking robust, reliable, and sustainable flooring options, steel grating remains the unequivocal choice.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP