1月 . 15, 2025 01:45

Back to list

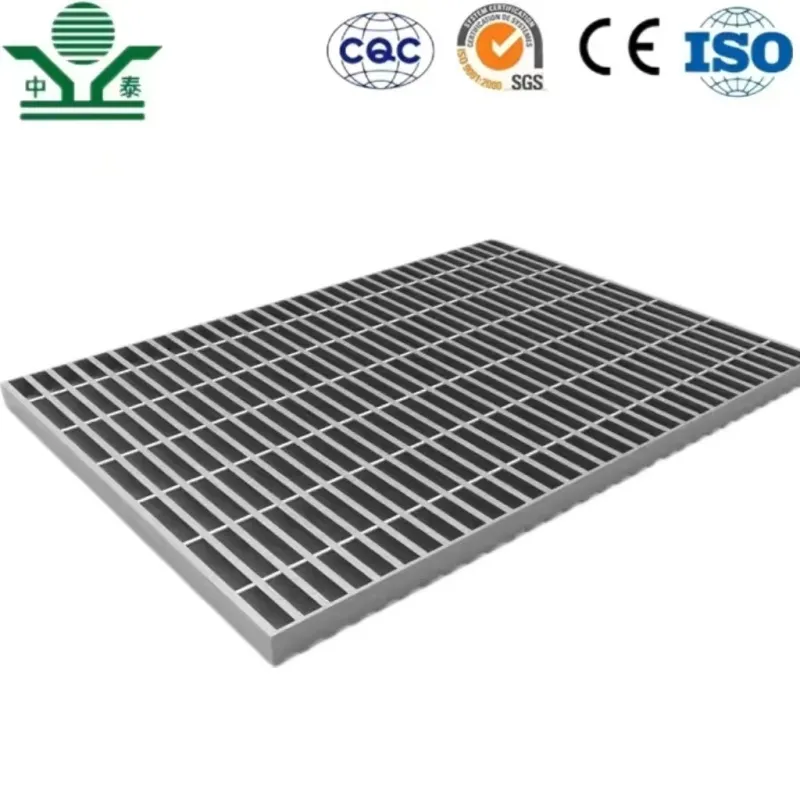

heavy duty grating

Heavy duty grating serves as the bedrock for many industrial and commercial infrastructures, characterized by its exceptional strength, durability, and versatility. Designed to withstand the rigors of harsh environments, heavy duty grating finds extensive applications in industries such as transportation, oil and gas, manufacturing, and construction. Its robustness is not just a matter of engineering excellence, but a testament to the expertise and specialized knowledge built into each piece, ensuring optimal performance and safety.

The credibility of heavy duty grating is further reinforced by its widespread use in essential infrastructure projects worldwide. Its endorsement by engineers and industry leaders underscores its authoritative standing as the go-to solution for heavy-duty flooring needs. When selecting grating, it is crucial to consider the specific requirements of each application, such as load-bearing capacity, environmental conditions, and potential exposure to corrosive elements. This process ensures the selected grating will deliver outstanding performance and longevity, tailored to the unique demands of the site. Additionally, for environments with stringent safety requirements, incorporating anti-slip surfaces in the grating design enhances worker protection. This feature is essential in wet or oily conditions, where the risk of slippage is heightened. Anti-slip grating provides the confidence workers need to perform tasks efficiently, without the fear of falling, thus promoting productivity and reducing downtime. In conclusion, heavy duty grating stands as a paragon of industrial excellence, expertly designed to meet the highest standards of performance and safety. Its proven track record and the expertise involved in its creation make it a trusted element in critical infrastructure and industrial settings. By choosing heavy duty grating, stakeholders can ensure their projects are equipped to endure the demands of modern industry, safeguarding both functionality and human safety. This commitment to quality and trustworthiness underlies every aspect of heavy duty grating, reaffirming its position as an indispensable component in the world of industrial applications.

The credibility of heavy duty grating is further reinforced by its widespread use in essential infrastructure projects worldwide. Its endorsement by engineers and industry leaders underscores its authoritative standing as the go-to solution for heavy-duty flooring needs. When selecting grating, it is crucial to consider the specific requirements of each application, such as load-bearing capacity, environmental conditions, and potential exposure to corrosive elements. This process ensures the selected grating will deliver outstanding performance and longevity, tailored to the unique demands of the site. Additionally, for environments with stringent safety requirements, incorporating anti-slip surfaces in the grating design enhances worker protection. This feature is essential in wet or oily conditions, where the risk of slippage is heightened. Anti-slip grating provides the confidence workers need to perform tasks efficiently, without the fear of falling, thus promoting productivity and reducing downtime. In conclusion, heavy duty grating stands as a paragon of industrial excellence, expertly designed to meet the highest standards of performance and safety. Its proven track record and the expertise involved in its creation make it a trusted element in critical infrastructure and industrial settings. By choosing heavy duty grating, stakeholders can ensure their projects are equipped to endure the demands of modern industry, safeguarding both functionality and human safety. This commitment to quality and trustworthiness underlies every aspect of heavy duty grating, reaffirming its position as an indispensable component in the world of industrial applications.

Next:

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP