Gen . 21, 2025 00:48

Back to list

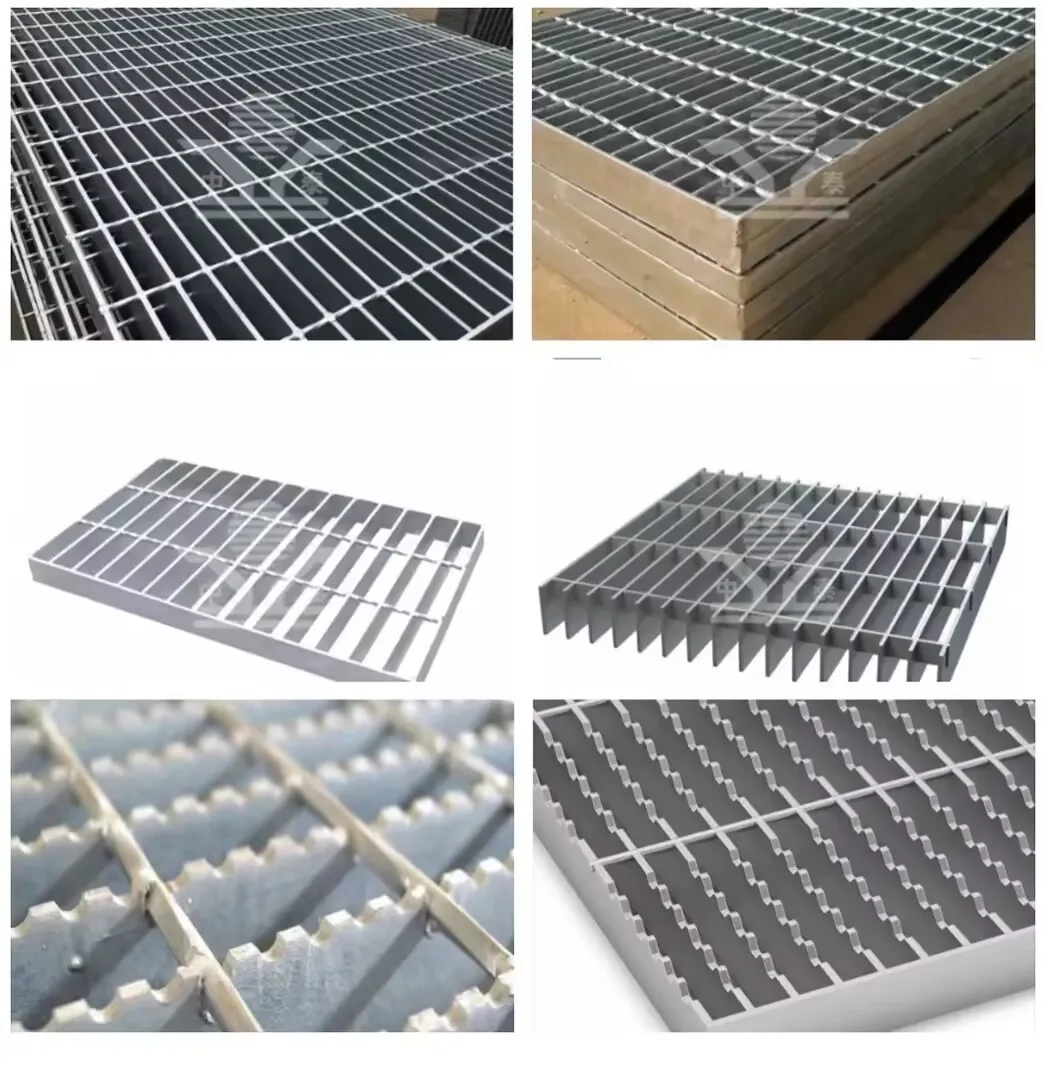

welded steel bar grating

Welded steel bar grating has become an essential component in various industries due to its versatility, strength, and durability. When companies seek to optimize their operational efficiency while ensuring safety and compliance, welded steel bar grating stands out as a reliable solution. Having worked with multiple industries and understanding their specific needs, I am confident in sharing insights that reflect authenticity and trustworthiness backed by real experience and comprehensive knowledge.

In real-world applications, companies that have integrated welded steel bar gratings report notable improvements in safety and operational efficiency. For instance, in chemical processing plants, the non-slip surface of gratings is a fundamental feature that prevents accidents, safeguarding workers and equipment. Meanwhile, energy sector companies value its resistance to harsh weather conditions, corrosion, and fire, crucial factors that ensure uninterrupted operations. Furthermore, installation processes for welded steel bar gratings are straightforward, allowing for time and cost-effective implementations. This ease of handling is achieved thanks to modular designs that enable quick adaptation to various spatial requirements and specific project needs. Contractors appreciate how these gratings can be cut and customized on-site, minimizing downtime and optimizing the use of resources. Emphasizing expertise, manufacturers now offer designs tailored to specific industry challenges, including serrated surface options for enhanced grip in oily environments or powder coatings that further augment corrosion resistance. These innovative solutions are driven by an in-depth understanding of market demands acquired through decades of industry engagement. Summing up, welded steel bar grating remains an indispensable part of infrastructure and industrial projects, supported by its proven performance and reliable quality. The combination of real-life application testimonials, adherence to stringent safety standards, and a commitment to environmental sustainability ensures this product's continuing relevance and trustworthiness in a competitive market. Selecting a provider with established authority and proven experience in the domain is crucial for companies aiming to leverage the full potential of welded steel bar grating, guaranteeing success across their various applications.

In real-world applications, companies that have integrated welded steel bar gratings report notable improvements in safety and operational efficiency. For instance, in chemical processing plants, the non-slip surface of gratings is a fundamental feature that prevents accidents, safeguarding workers and equipment. Meanwhile, energy sector companies value its resistance to harsh weather conditions, corrosion, and fire, crucial factors that ensure uninterrupted operations. Furthermore, installation processes for welded steel bar gratings are straightforward, allowing for time and cost-effective implementations. This ease of handling is achieved thanks to modular designs that enable quick adaptation to various spatial requirements and specific project needs. Contractors appreciate how these gratings can be cut and customized on-site, minimizing downtime and optimizing the use of resources. Emphasizing expertise, manufacturers now offer designs tailored to specific industry challenges, including serrated surface options for enhanced grip in oily environments or powder coatings that further augment corrosion resistance. These innovative solutions are driven by an in-depth understanding of market demands acquired through decades of industry engagement. Summing up, welded steel bar grating remains an indispensable part of infrastructure and industrial projects, supported by its proven performance and reliable quality. The combination of real-life application testimonials, adherence to stringent safety standards, and a commitment to environmental sustainability ensures this product's continuing relevance and trustworthiness in a competitive market. Selecting a provider with established authority and proven experience in the domain is crucial for companies aiming to leverage the full potential of welded steel bar grating, guaranteeing success across their various applications.

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP