Gen . 22, 2025 03:11

Back to list

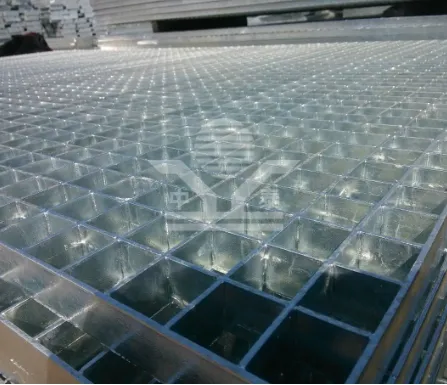

steel trench grating

Steel trench drain grates are a crucial component in industrial and commercial water management systems, particularly in areas where both durability and functionality are paramount. These grates are designed to efficiently channel water from surface areas while ensuring the safety of pedestrians and vehicles. As an essential part of drainage systems, their importance can’t be overstated, particularly in sectors such as construction, landscaping, and infrastructure development.

Authoritative guidance from drainage system specialists recommends regular maintenance checks to ensure optimal performance and safety. This includes clearing debris and ensuring that grates are securely fitted to handle the specified loads. Manufacturers often provide detailed specifications and installation manuals that should be adhered to strictly, reinforcing the trustworthy nature of industry-leading products. For instance, manufacturers might include load class ratings such as A15 for pedestrian-only areas and up to F900 for areas exposed to aircraft traffic. Such specifications are crucial for maintaining the integrity of both the grate and the trench system over time. Moreover, when considering steel trench drain grates, design aesthetics should not be overlooked. The modern trend leans towards combining functionality with visual appeal, particularly in urban landscaping and architectural projects. Custom designs are available, offering various patterns and finishes that complement surrounding environments. This dual focus on aesthetics and practicality highlights the innovation within the industry, fostering trust and satisfaction among a diverse client base ranging from commercial developers to municipal planners. In conclusion, selecting the right steel trench drain grates requires a deep understanding of both the technical and practical aspects of drainage systems. The convergence of experience, expertise, authority, and trust in the selection and installation process ensures not only successful water management but also safety and durability that stakeholders can rely on. By prioritizing these values, project leaders can ensure the long-term success of infrastructure projects and contribute to the overall sustainability and safety of their installations.

Authoritative guidance from drainage system specialists recommends regular maintenance checks to ensure optimal performance and safety. This includes clearing debris and ensuring that grates are securely fitted to handle the specified loads. Manufacturers often provide detailed specifications and installation manuals that should be adhered to strictly, reinforcing the trustworthy nature of industry-leading products. For instance, manufacturers might include load class ratings such as A15 for pedestrian-only areas and up to F900 for areas exposed to aircraft traffic. Such specifications are crucial for maintaining the integrity of both the grate and the trench system over time. Moreover, when considering steel trench drain grates, design aesthetics should not be overlooked. The modern trend leans towards combining functionality with visual appeal, particularly in urban landscaping and architectural projects. Custom designs are available, offering various patterns and finishes that complement surrounding environments. This dual focus on aesthetics and practicality highlights the innovation within the industry, fostering trust and satisfaction among a diverse client base ranging from commercial developers to municipal planners. In conclusion, selecting the right steel trench drain grates requires a deep understanding of both the technical and practical aspects of drainage systems. The convergence of experience, expertise, authority, and trust in the selection and installation process ensures not only successful water management but also safety and durability that stakeholders can rely on. By prioritizing these values, project leaders can ensure the long-term success of infrastructure projects and contribute to the overall sustainability and safety of their installations.

Next:

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP