The Versatility and Applications of Stainless Steel Perforated Sheets

Stainless steel perforated sheets are a remarkable material known for their strength, durability, and unique aesthetic appeal. These sheets, characterized by their rows of holes punched into a solid sheet of stainless steel, serve a multitude of functions across various industries. This article will explore the properties, production methods, and applications of stainless steel perforated sheets, highlighting their significance in modern engineering and design.

One of the core advantages of stainless steel is its resistance to corrosion and rust, making it an ideal choice for many outdoor and industrial applications. The addition of perforations to the material enhances its utility without compromising its structural integrity. The design can be customized with varying hole sizes, shapes, and patterns, allowing for tailored solutions that meet specific functional requirements. From filtering and ventilation to aesthetic applications, the versatility of stainless steel perforated sheets is unparalleled.

The production of stainless steel perforated sheets typically involves a process known as punching, where a die and a punch are used to create holes in the sheet. This can be achieved using various methods, including laser cutting and CNC machining. The choice of technique depends on the desired precision, thickness of the material, and specific application requirements. Once formed, the sheets can undergo additional treatment, like polishing or coating, to further enhance their performance and visual appeal.

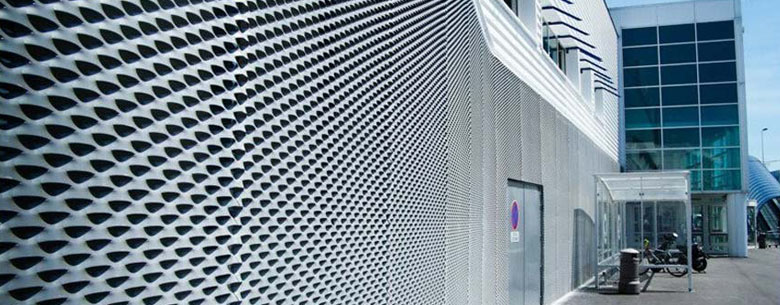

In terms of applications, stainless steel perforated sheets find their use in a wide array of industries. In construction and architecture, they are often employed as decorative facades, providing both ventilation and light while maintaining privacy and aesthetics. Designers favor these sheets for their ability to create visually striking patterns that can transform ordinary structures into eye-catching landmarks.

stainless steel perforated

In the automotive and aerospace industries, perforated stainless steel is utilized for noise reduction and weight savings. By incorporating perforated components, manufacturers can achieve significant reductions in engine noise while also contributing to the overall lightweight structure of vehicles and aircraft. Moreover, these sheets are crucial in filtration systems, which require effective liquid and air filtration solutions without hindering airflow or fluid movement.

Another vital application lies in the food and beverage industry, where stainless steel perforated sheets are used in machinery and production equipment. They ensure cleanliness, hygiene, and compliance with food safety standards, making them an indispensable part of processing systems.

The mining and mineral processing industries also benefit from the use of stainless steel perforated sheets in separating and sizing materials. The durability and corrosion resistance of stainless steel make it suitable for harsh environments, where traditional materials might fail.

In conclusion, stainless steel perforated sheets exemplify a blend of functionality, durability, and aesthetic versatility. Their wide-ranging applications across various sectors underline their critical role in modern manufacturing and design. As industries continue to evolve and demand higher standards for materials, the importance of stainless steel perforated sheets will only grow, cementing their status as a fundamental component in many engineering solutions. Whether it’s for practical functions or architectural beauty, these sheets demonstrate unparalleled adaptability and performance.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.