Understanding Floor Grating Prices A Comprehensive Guide

When it comes to industrial flooring solutions, floor grating is a popular choice due to its durability, safety, and versatility. Floor grating systems are used in various settings, from commercial buildings to manufacturing plants, providing a stable footpath and allowing for ventilation and drainage. Given the importance of these facilities, understanding floor grating prices becomes essential for budgeting and project planning. In this article, we will explore the factors that influence floor grating prices, the different materials available, and the overall benefits of investing in quality floor grating systems.

Factors Influencing Floor Grating Prices

1. Material Type The material of the grating has a significant impact on the price. Common materials include steel, aluminum, fiberglass, and plastic. Steel is typically the most economical option, but it can be subject to corrosion, which may lead to additional maintenance costs. Aluminum, while more expensive, is lightweight and resistant to corrosion, making it suitable for environments that require durability without heavy weight. Fiberglass grating offers excellent resistance to chemicals and is often used in harsh environments. Plastic grating, while the least expensive, may not provide the same level of support as metal alternatives.

2. Load Capacity Depending on the expected traffic and load on the grating, different thicknesses and designs will be necessary. Heavier loads require thicker gratings made from stronger materials, which will consequently increase the price. It’s crucial to assess the load requirements for your specific application to avoid over or under-spending on your grating solution.

3. Size and Customization Standard sizes of floor grating are often less expensive due to reduced manufacturing costs. However, custom-sized grating can lead to higher expenses. Whenever possible, opting for standard sizes can help manage costs, while still meeting safety and functional requirements. Custom designs may be necessary for unique applications but should be budgeted accordingly.

4. Surface Finish and Coatings The surface finish also affects the price. Gratings can come with anti-slip coatings, which enhance safety, especially in wet or oily environments. Additionally, galvanized coatings can protect against rust and corrosion, adding to the overall cost but potentially saving money on maintenance in the long run.

5. Installation Requirements Floor grating installation can vary widely in cost based on the complexity of the installation. Simple installations may be more straightforward and less costly, while intricate installations that involve custom fittings or challenging environments may require professional assistance, raising the overall expense.

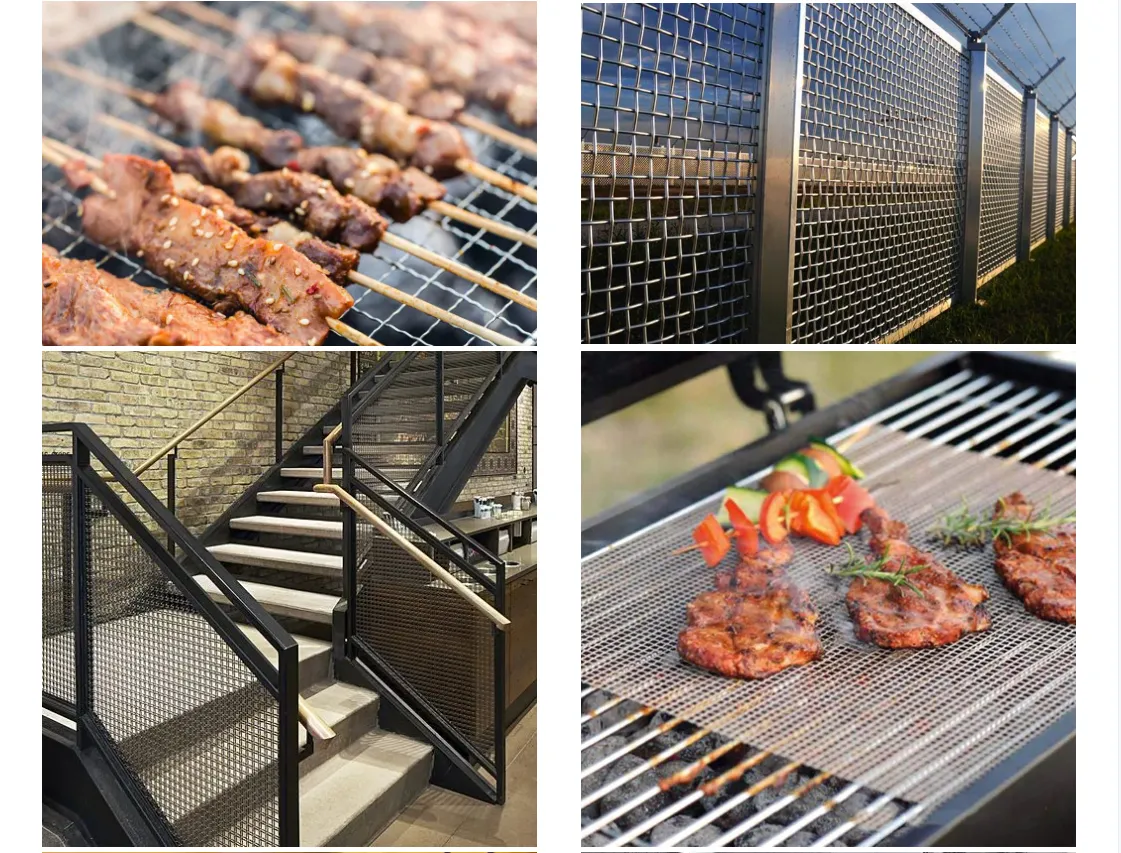

floor grating price

Comparing Floor Grating Options

When comparing floor grating options, it’s advisable to request quotes from multiple suppliers. This allows for a well-rounded view of market pricing and can lead to better deals through negotiation. Ensure to compare not just base prices, but also shipping costs, lead times, and warranty options. Some suppliers may offer discounts for bulk purchases, which can significantly reduce costs for large projects.

The Benefits of Quality Floor Grating

While price is undoubtedly a crucial factor, the benefits of investing in quality floor grating should not be overlooked. High-quality grating can enhance workplace safety by reducing slip and fall hazards, improve the overall operational efficiency by allowing water drainage and air circulation, and lead to longer lifespan with lower maintenance costs.

Choosing the right floor grating also contributes to regulatory compliance in many industries, ensuring that safety and health standards are met. This proactive approach can save businesses money in fines and liability claims over time.

Conclusion

In summary, understanding the factors influencing floor grating prices is vital for making informed purchasing decisions. Material choice, load capacity, size, surface finish, and installation requirements all play critical roles in determining overall costs. By carefully evaluating these elements and comparing different suppliers, businesses can find the right flooring solutions that fit their budget while meeting safety and functional needs. Investing in quality floor grating ultimately pays off, ensuring a safer, more efficient environment for all.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.