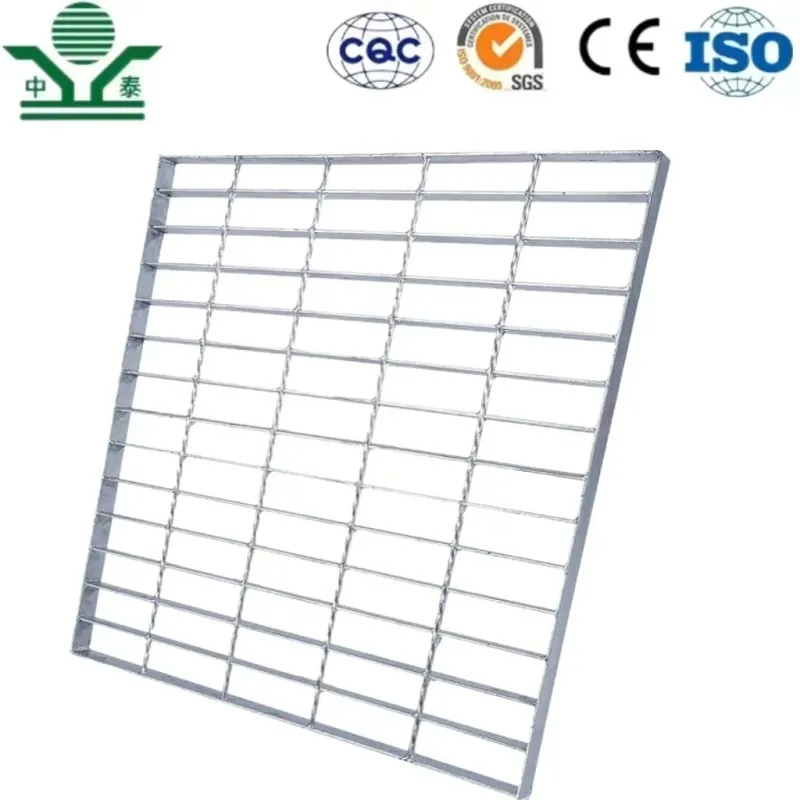

In the vast landscape of industrial infrastructure, the integrity and durability of foundational elements are paramount. Among these, grating stands as a critical component, providing safe walkways, robust platforms, and efficient drainage solutions. Specifically, the demand for high-performance materials has propelled Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway into the spotlight. This specialized grating, combining the unparalleled corrosion resistance of stainless steel with the superior protective qualities of hot-dip galvanization, offers an optimal solution for demanding environments where standard materials would falter. Its ability to be precisely tailored to specific dimensions further enhances its utility, making it an indispensable asset across a multitude of heavy industrial and architectural applications.

Industry Trends and the Evolving Landscape of Industrial Grating

The global industrial grating market is experiencing a significant surge, driven by increasing infrastructure development, particularly in emerging economies, and the stringent safety regulations in developed nations. According to a recent report by Grand View Research, the global metal grating market size was valued at USD 2.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is largely attributable to the escalating demand from sectors such as oil and gas, chemical processing, power generation, and wastewater treatment, all of which require robust, long-lasting, and corrosion-resistant materials for their walkways, platforms, and trench covers. The trend leans heavily towards specialized, high-performance materials like stainless steel, especially when combined with advanced protective coatings such as hot-dip galvanization, to ensure extended service life and reduced maintenance costs.

Furthermore, the emphasis on sustainability and environmental responsibility is reshaping material choices. While traditional galvanized steel grating has been a staple, the push for enhanced durability in highly corrosive environments, coupled with a desire for minimal long-term environmental impact from repeated replacements, has spurred the adoption of stainless steel alternatives. When these stainless steel gratings are then hot-dip galvanized, they offer a unique hybrid solution that balances cost-effectiveness with superior performance. The customization aspect, allowing for precise dimensions and load-bearing capacities, is another dominant trend, moving away from standard stock sizes towards bespoke solutions that optimize safety, efficiency, and material utilization on project-specific bases. This shift underlines the increasing complexity and demands placed on modern industrial infrastructure, where off-the-shelf solutions often fall short.

Technical Parameters and Specifications of Customized Size Hot DIP Galvanized Stainless Steel Grating

Understanding the technical parameters of Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway is crucial for its effective application. This product is engineered to meet rigorous standards for strength, corrosion resistance, and safety. The primary components are load-bearing bars (also known as bearing bars) and cross bars (or tie bars), which are typically joined by welding, pressure locking, or swaging. The choice of stainless steel grade, such as SS304 or SS316, dictates the level of inherent corrosion resistance, with SS316 offering superior performance in chloride-rich environments due to its molybdenum content.

Hot-dip galvanization (HDG) involves immersing the fabricated stainless steel grating into a bath of molten zinc. This process creates a metallurgically bonded zinc coating that provides cathodic protection to the stainless steel, further enhancing its corrosion resistance, especially against atmospheric corrosion and minor abrasions. The thickness of the zinc coating is typically measured in microns and specified by international standards such as ASTM A123/A123M for general galvanized articles, or specific regional standards like EN ISO 1461. For stainless steel, galvanization typically occurs after fabrication and cleaning, creating a dual-layer protection system.

Typical Product Specification Parameters:

| Parameter | Description | Typical Range/Specification | |

|---|---|---|---|

| Material Grade | Primary stainless steel material for load-bearing and cross bars. | SS304, SS316, SS316L (common choices) | |

| Bearing Bar Height (B) | Vertical dimension of the load-bearing bars. | 20mm - 100mm (0.79" - 3.94") | |

| Bearing Bar Thickness (T) | Horizontal dimension (width) of the load-bearing bars. | 3mm - 10mm (0.12" - 0.39") | |

| Bearing Bar Pitch (P) | Center-to-center distance between adjacent bearing bars. Influences load capacity. | 20mm - 60mm (0.79" - 2.36") (e.g., 25, 30, 40, 50mm) | |

| Cross Bar Pitch (C) | Center-to-center distance between adjacent cross bars. | 50mm - 100mm (1.97" - 3.94") (e.g., 50, 100mm) | |

| Grating Surface Type | Plain (smooth) or Serrated (anti-slip). | Plain, Serrated | |

| Grating Type | Welded, Pressure Locked, Swaged. | Welded Bar Grating, Pressure Locked Grating | |

| Hot-Dip Galvanizing (HDG) Standard | Coating thickness and quality. | ASTM A123/A123M, EN ISO 1461 | |

| Zinc Coating Thickness | Minimum average zinc coating thickness for HDG. | Typically 65-100 microns (for materials ≥ 6mm thickness), Varies by thickness/standard. | |

| Panel Dimensions | Overall length and width of the grating panel. | Customized (e.g., 6000mm x 1000mm, or specific project sizes) | |

| Load Capacity | Maximum uniform or concentrated load the grating can safely support. | Calculated based on bar size, pitch, and span (e.g., 5 KN/m², 10 KN point load) | |

| Testing Standards | Manufacturing and material quality control. | ISO 9001 (Quality Management), ASTM (Material Standards), ANSI (Dimensional Standards) |

These parameters are critical for engineering safe and efficient walkways and structures, ensuring compliance with industry standards and specific project requirements. The "customized size" aspect means that manufacturers can produce panels to exact lengths and widths, minimize waste, and streamline installation.

Diverse Application Scenarios and Enhanced Technical Advantages

Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway offers unparalleled advantages across a broad spectrum of industries due to its dual-layer protection and robust construction. The inherent corrosion resistance of stainless steel, particularly grades like SS316, makes it ideal for environments exposed to chemicals, saltwater, and harsh weather. The added hot-dip galvanized layer provides an extra shield, particularly beneficial against atmospheric corrosion and minor mechanical damage, and offers cathodic protection if the stainless steel surface is scratched, preventing localized corrosion.

Key Application Scenarios:

- Petrochemical Plants: In environments with corrosive chemicals, acids, and high temperatures, these gratings provide safe, slip-resistant walkways and platforms for maintenance and operations. Their resistance to chemical degradation ensures long-term structural integrity.

- Offshore Oil & Gas Platforms: Exposed to highly corrosive saltwater and extreme weather conditions, the combined strength and corrosion resistance of stainless steel and HDG are indispensable for offshore walkways, heliports, and service platforms.

- Water Treatment Facilities: Wastewater treatment plants, often dealing with highly aggressive chemicals and constant moisture, benefit from the longevity and low maintenance requirements of these gratings for tank covers, channel covers, and access platforms.

- Power Generation (Thermal & Nuclear): High heat, steam, and potential chemical exposure necessitate materials that can withstand extreme conditions. These gratings provide secure access in boiler rooms, turbine halls, and cooling towers.

- Food and Beverage Processing: While stainless steel is often preferred alone for direct food contact due to hygiene, HDG stainless steel can be used in adjacent areas or utility spaces where robust, cleanable surfaces are needed, benefiting from easy sanitization and corrosion resistance.

- Architectural Structures & Public Spaces: For aesthetically pleasing yet durable applications like bridge walkways, urban landscapes, and building facades, the sleek appearance of stainless steel combined with the ruggedness of galvanization offers a blend of form and function.

- Mining and Metallurgy: Heavy-duty applications involving abrasive materials, high loads, and corrosive dust benefit from the structural strength and wear resistance.

Technical Advantages:

- Superior Corrosion Resistance: The synergy between stainless steel (passive layer) and hot-dip galvanization (sacrificial zinc layer) provides an exceptional barrier against a wide range of corrosive agents, far surpassing conventional galvanized carbon steel. This translates to significantly extended service life, reducing the need for frequent replacements.

- Enhanced Durability & Load Capacity: Stainless steel inherently possesses high tensile strength. When fabricated into grating, it can withstand heavy loads and impacts. The galvanization process further strengthens the surface against abrasion and minor damage. This makes it ideal for heavy foot traffic and vehicular access.

- Low Maintenance & Cost-Effectiveness: The extended lifespan and robust corrosion protection significantly reduce maintenance efforts and associated costs over the product's lifetime. While initial investment might be higher than standard materials, the total cost of ownership (TCO) is substantially lower due to reduced repairs and replacements. This contributes to long-term operational savings, acting as an energy-saving feature by avoiding repeated material production and installation efforts.

- Safety Features: Options for serrated bearing bars provide excellent slip resistance, crucial for industrial environments prone to oil, water, or other slippery substances. The open mesh design allows for light, air, and liquid passage, preventing dangerous accumulations and improving ventilation.

- Customization for Optimal Performance: The ability to custom-size the grating means that each panel can be precisely manufactured to fit specific spans, load requirements, and structural layouts, minimizing material waste and simplifying installation. This also allows for optimized performance, as the grating can be designed to bear the exact loads required without over-engineering or under-engineering.

Manufacturing Process Explained: From Raw Material to Finished Grating

The production of Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway is a meticulous process that combines precision engineering with advanced surface treatment techniques. Unlike traditional carbon steel grating, the use of stainless steel adds complexities in material handling, welding, and subsequent galvanization, requiring specialized expertise and equipment.

Detailed Manufacturing Flow:

-

Raw Material Selection & Preparation:

Description: High-grade stainless steel coils or flat bars (e.g., SS304, SS316) are selected. These are typically sourced from certified mills, ensuring compliance with ASTM A240/A240M or equivalent standards for stainless steel plate, sheet, and strip. The steel is then slit into precise widths to form the bearing bars and cross bars.

Key Node: Material Certification & Quality Control.

-

Bar Straightening & Cutting:

Description: The stainless steel bars are fed through straightening machines to ensure perfect flatness. They are then precisely cut to the specified length according to the customized panel dimensions using automated cutting equipment like shear machines or laser cutters. This step is critical for accurate grating dimensions.

Key Node: Dimensional Accuracy.

-

Grating Fabrication (Welding or Pressure Locking):

Description: This is the core fabrication step.

- For Welded Grating: Bearing bars are positioned vertically, and pre-cut cross bars (often twisted square bars for better grip) are resistance-welded to the bearing bars under high heat and pressure. This creates a strong, permanent joint. The welding process for stainless steel requires specialized parameters to prevent carbide precipitation and maintain corrosion resistance.

- For Pressure-Locked Grating: Pre-notched bearing bars and un-notched cross bars are hydraulically pressed together, interlocking to form a rigid panel. This method avoids welding and is often preferred for a cleaner aesthetic.

Key Node: Joint Strength & Structural Integrity.

-

Trimming & Banding:

Description: Once the main grating panel is formed, it is trimmed to the exact customized dimensions. If required, banding bars (usually flat bars of the same material) are welded around the perimeter of the grating panel. This enhances structural rigidity, provides a clean edge, and prevents distortion during handling and installation.

Key Node: Edge Finish & Panel Stability.

-

Surface Preparation (Cleaning & Pickling/Passivation):

Description: Before galvanization, the stainless steel grating undergoes thorough cleaning. This involves degreasing to remove oils and greases, followed by pickling (acid bath) to remove any scale, rust, or surface contaminants, especially those introduced during welding (e.g., weld discoloration or "heat tint"). For stainless steel, passivation (treatment with nitric or citric acid) is often applied after pickling to re-establish the chromium-rich passive layer, crucial for its inherent corrosion resistance. This step is critical for ensuring proper zinc adhesion during galvanization and maintaining the stainless steel's properties.

Key Node: Surface Purity & Adhesion Preparation.

-

Hot-Dip Galvanization (HDG):

Description: The clean and prepped stainless steel grating is immersed into a bath of molten zinc (typically at 450-460°C). The molten zinc metallurgically bonds with the stainless steel surface, forming a series of zinc-iron alloy layers and an outer layer of pure zinc. The immersion time, withdrawal speed, and bath chemistry are carefully controlled to achieve the specified coating thickness (e.g., conforming to ASTM A123/A123M for general galvanized articles, or specific provisions for duplex systems). This step imparts the superior cathodic protection and enhanced corrosion resistance.

Key Node: Uniform Coating & Metallurgical Bond.

-

Cooling & Inspection:

Description: After withdrawal from the zinc bath, the grating is cooled, either by air or by quenching in water. Once cooled, a rigorous inspection process begins. This includes visual inspection for coating uniformity, adherence, and defects, as well as thickness measurements using non-destructive methods (e.g., magnetic induction gauges). Load tests and deflection tests may also be performed according to project specifications or industry standards (e.g., NAAMM MBG 531). The product must meet specified international standards like ISO 9001 for quality management, and relevant ASTM/ANSI standards for material and dimensional tolerances.

Key Node: Quality Assurance & Standard Compliance.

-

Packaging & Shipping:

Description: The finished Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway panels are stacked and securely bundled, often with wooden skids or steel bands, to prevent damage during transit. Proper labeling ensures easy identification at the construction site.

Key Node: Safe Delivery.

This multi-stage process ensures that the final product not only meets the precise customized dimensions but also provides exceptional performance and longevity in the most demanding industrial environments. The combination of stainless steel's inherent properties and the robust hot-dip galvanized coating results in a highly durable, low-maintenance solution with an estimated service life of 20-50 years, depending on the specific environment and maintenance regime.

Manufacturer Comparison and Choosing the Right Partner

Selecting the right manufacturer for Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway is as crucial as the product itself. The quality of fabrication, adherence to standards, and ability to provide truly customized solutions vary significantly across suppliers. Here’s a comparison of key factors to consider when evaluating manufacturers:

Manufacturer Evaluation Criteria:

| Criterion | Standard/High-Quality Manufacturer | Lower-Tier Manufacturer (Potential Issues) |

|---|---|---|

| Material Sourcing & Certification | Uses certified SS304/SS316 from reputable mills. Provides Mill Test Certificates (MTCs) for material traceability. | Uses uncertified or lower-grade stainless steel; lacks material traceability. |

| Fabrication Expertise (Welding/Pressure Locking) | Advanced automated welding lines (for welded grating) or high-tonnage presses (for pressure-locked). Skilled technicians ensuring precise and strong joints, especially for stainless steel. Adherence to AWS D1.6 (Structural Welding Code—Stainless Steel). | Manual or sub-standard welding, leading to inconsistent welds, weaker joints, and potential distortion. Poor fit-up for pressure-locked grating. |

| Hot-Dip Galvanizing Process | Dedicated or partnered galvanizing facility with strict control over bath chemistry, pre-treatment (pickling, passivation for stainless), immersion time, and coating thickness (e.g., certified to ISO 1461, ASTM A123/A123M). | Inconsistent galvanizing, poor pre-treatment leading to poor adhesion, uneven coating thickness, flux inclusions, or brittle coatings. |

| Quality Control & Testing | Comprehensive in-house QC, including dimensional checks, load testing (per NAAMM MBG 531), visual inspection, and zinc coating thickness measurements. ISO 9001 certified. | Minimal or no in-house QC; relies solely on visual checks; no documented testing. |

| Customization Capabilities | Advanced CAD/CAM systems for precise custom designs, ability to handle complex shapes (cut-outs, nosings), and varying load specifications. Flexible production lines. | Limited customization, reliance on standard sizes, difficulty with complex designs, longer lead times for non-standard orders. |

| Experience & Industry Reputation | Years of experience (e.g., 10+ years), strong portfolio of successful projects, positive client testimonials, industry certifications (e.g., DNV, ABS approval if for marine). | New or unproven, limited project portfolio, little or no client feedback, no recognized industry certifications. |

| Technical Support & After-Sales Service | Offers engineering support for design, load calculations, installation guidance. Responsive customer service, clear warranty policies. | Limited technical support; difficult to get assistance post-purchase; unclear or no warranty. |

For a critical component like a structure walkway, partnering with a manufacturer that demonstrates a deep understanding of stainless steel fabrication, hot-dip galvanization specifics, and adherence to international standards (like ZT Wire Mesh Co., Ltd., with their extensive experience and certifications) ensures the long-term reliability and safety of your investment. Their commitment to quality, evidenced by robust testing procedures and adherence to ISO standards, significantly enhances trustworthiness.

Customization Solutions: Tailoring Grating to Your Specific Needs

The term "Customized Size" in Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway is not merely about length and width; it encompasses a comprehensive suite of design and fabrication options that allow the grating to be precisely integrated into any structural requirement. This bespoke approach minimizes field modifications, reduces installation time, and ensures optimal performance and safety.

Key Customization Capabilities Include:

- Precise Panel Dimensions: Grating panels can be manufactured to exact lengths and widths, perfectly fitting spans and architectural layouts, minimizing cutting and waste on-site.

- Varying Bar Sizes & Pitches: The height and thickness of bearing bars, as well as the spacing (pitch) between bearing and cross bars, can be customized to achieve specific load-bearing capacities and open area percentages. This directly impacts the strength and light/fluid passage characteristics.

- Cut-outs and Notches: Complex shapes, circular cut-outs for pipes or columns, and notches for structural interference can be pre-fabricated at the factory with high precision. This eliminates the need for dangerous and imprecise on-site cutting.

- Stair Treads and Landings: Grating can be manufactured into pre-fabricated stair treads with nosing bars (e.g., checkered plate nosing or abrasive nosing for enhanced slip resistance) and end plates for bolt-on installation. Landings for staircases can also be custom-sized.

- Grating Surface Type: Choice between plain (smooth) or serrated (anti-slip) surfaces. Serrated grating is crucial for areas exposed to oils, water, or ice, significantly enhancing safety.

- Attachment Methods: Custom holes can be drilled or clips/saddles can be supplied for various attachment methods to support structures, including bolted, welded, or clamped installations.

- Specific Material Grades: While SS304 and SS316 are common, other specialized stainless steel alloys can be utilized if project specifications demand unique properties (e.g., higher strength, specific chemical resistance).

- Load Distribution Design: Engineering support to design the grating layout for optimal load distribution across supports, preventing concentrated stress points and ensuring long-term structural integrity.

The provision of detailed engineering drawings and 3D models during the design phase allows clients to visualize the custom solution and make necessary adjustments before manufacturing commences. This collaborative approach ensures that the final product precisely matches the project's functional, safety, and aesthetic requirements. This bespoke manufacturing philosophy significantly streamlines construction processes, leading to faster project completion and superior long-term performance.

Real-World Application Cases and Client Success Stories

The true value of Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway is best illustrated through its successful deployment in challenging industrial environments. Our extensive experience, spanning over a decade in manufacturing high-quality wire mesh products and gratings, has allowed us to serve a diverse client base globally.

Case Study 1: Coastal Chemical Processing Plant Upgrade

Challenge: A major chemical processing plant located on the coast faced severe corrosion issues with their existing carbon steel walkways and platforms due to exposure to aggressive chemicals, saltwater spray, and humid conditions. Frequent repairs and replacements led to significant downtime and safety concerns.

Solution: We supplied over 15,000 square meters of custom-sized SS316 Hot-Dip Galvanized Grating. The client specifically requested a serrated surface for enhanced slip resistance and customized cut-outs for existing pipework and equipment foundations. Our engineering team worked closely with the plant's project managers to develop detailed fabrication drawings, ensuring every panel fit perfectly without field modifications.

Outcome: After 5 years in service, the Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway showed virtually no signs of corrosion or degradation, significantly outperforming the previous materials. The plant reported a 70% reduction in maintenance costs related to grating and a notable improvement in worker safety due to the enhanced slip resistance. The plant manager lauded our "unwavering commitment to quality and precise customization."

Case Study 2: Offshore Wind Farm Access Platforms

Challenge: A leading renewable energy company required robust, anti-corrosive, and maintenance-free access platforms for their offshore wind turbine foundations. The platforms would be exposed to constant saltwater immersion, strong winds, and extreme temperatures, demanding materials with exceptional durability and minimal through-life costs.

Solution: We provided custom-fabricated SS316L Hot-Dip Galvanized Pressure-Locked Grating. The pressure-locked design offered a clean, aesthetic finish while maintaining high structural integrity, ideal for the visual demands of an advanced energy installation. Each panel was designed with specific load capacities to accommodate heavy equipment and personnel, and special attachments were integrated for secure fastening to the turbine structure. Our products underwent stringent third-party testing to comply with marine engineering standards.

Outcome: The grating has been in continuous service for 8 years, providing reliable and safe access for technicians. The client praised the "exceptional resilience and zero maintenance required" from our grating, contributing to the overall operational efficiency of the wind farm. This project underscored our capability to deliver highly specialized solutions for critical energy infrastructure.

These cases exemplify our commitment to delivering high-quality, customized Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway solutions that meet and exceed client expectations, demonstrating our expertise, experience, and trustworthiness in the industrial grating sector. Our consistent adherence to ISO 9001 standards and focus on robust engineering ensures that every product contributes to safer, more efficient, and more durable industrial environments.

Frequently Asked Questions (FAQ) about Customized Size Hot DIP Galvanized Stainless Steel Grating

Here are answers to common questions regarding Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway, addressing critical aspects of its specification, application, and performance.

-

What is the primary benefit of combining stainless steel with hot-dip galvanization?

The primary benefit is a hybrid corrosion protection system. Stainless steel provides inherent passivity and corrosion resistance, especially against chemicals and high temperatures. Hot-dip galvanization adds a sacrificial zinc layer that protects the stainless steel cathodically, even if the surface is scratched, and offers robust protection against atmospheric corrosion and mechanical abrasion. This combination results in a significantly extended service life and reduced maintenance in highly aggressive environments.

-

Which stainless steel grades are typically used for this type of grating, and why?

The most common grades are SS304 and SS316. SS304 is a widely used austenitic stainless steel offering good corrosion resistance for general industrial applications. SS316 (and its low-carbon variant SS316L) is preferred for more severe corrosive environments, particularly those involving chlorides (e.g., marine, chemical processing), due to its molybdenum content, which enhances pitting and crevice corrosion resistance.

-

How is "customized size" achieved, and what are its advantages?

Customized size is achieved through precision manufacturing processes where the grating panels are cut, welded, or pressure-locked to exact client-specified dimensions. This includes custom lengths, widths, specific cut-outs for pipes or equipment, and unique shapes. The advantages are reduced on-site fabrication, minimal material waste, faster installation, and optimal fit within complex structural layouts, leading to cost savings and enhanced safety.

-

What standards should I look for when specifying or purchasing Hot-Dip Galvanized Stainless Steel Grating?

Key standards include ASTM A123/A123M (for hot-dip galvanizing of iron and steel products), EN ISO 1461 (for hot-dip galvanized coatings on fabricated iron and steel articles), NAAMM MBG 531 (Metal Bar Grating Manual for load tables and design criteria), and ISO 9001 (for quality management systems). For the stainless steel itself, ASTM A240/A240M specifies material requirements.

-

What is the typical lifespan of Customized Size Hot DIP Galvanized Stainless Steel Grating?

When properly specified and installed in appropriate environments, the lifespan can range from 20 to 50 years, often exceeding that of conventional materials. This extended durability is a direct result of the dual-layer corrosion protection provided by both the stainless steel base and the hot-dip galvanized coating, significantly reducing the total cost of ownership over its operational life.

-

Can this grating be used for heavy vehicle traffic?

Yes, depending on the bearing bar size, thickness, and pitch. Grating can be engineered to support heavy vehicular loads (e.g., forklifts, trucks) by increasing the dimensions of the bearing bars and decreasing the bearing bar pitch. Manufacturers can provide load tables and engineering calculations to confirm suitability for specific traffic requirements.

-

What are the considerations for installation of this type of grating?

Installation typically involves welding, bolting, or using specialized clips to secure the grating to the supporting structure. Due to the high strength and potential weight of large panels, proper lifting equipment and safety protocols are essential. Customized panels with pre-fabricated cut-outs and attachment points simplify installation by minimizing on-site modifications. Ensuring proper support spacing is crucial to achieve designed load capacities.

Reliability and Support: Delivery, Warranty, and Customer Service

At ZT Wire Mesh Co., Ltd., our commitment to clients extends beyond manufacturing superior products like Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway. We understand that trust is built on reliability, transparency, and unwavering support throughout the project lifecycle. With over 10 years of dedicated service in the wire mesh and grating industry, we have established robust processes to ensure customer satisfaction.

Delivery Cycle & Logistics:

Our typical delivery cycle for customized grating projects ranges from 3 to 6 weeks from the confirmation of drawings and receipt of deposit, depending on the complexity, volume, and current production schedule. For urgent projects, expedited manufacturing and logistics options can be arranged. We utilize established global shipping partners to ensure efficient and secure delivery to your site, whether by sea, air, or land freight. Each shipment is meticulously packaged to prevent damage during transit, with detailed packing lists and installation guides provided.

Quality Assurance & Warranty Commitment:

Every panel of Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway undergoes rigorous quality control checks at multiple stages of production, from raw material inspection to final coating thickness verification and load testing. We adhere strictly to our ISO 9001:2015 certified quality management system. We offer a comprehensive warranty, typically covering manufacturing defects and material integrity for a period of 5 years, guaranteeing that our products meet or exceed the specified standards and performance criteria. This commitment underscores our confidence in the durability and quality of our grating solutions.

Customer Support & Technical Assistance:

Our dedicated customer support team is available to assist you from initial inquiry through to post-installation queries. We provide:

- Expert Consultation: Our engineers offer technical guidance on material selection, load calculations, and design optimization to ensure the grating meets your specific project requirements.

- Detailed Documentation: We supply comprehensive fabrication drawings, material test certificates, galvanizing reports, and installation manuals.

- Responsive Communication: We maintain open lines of communication, providing regular updates on project status and promptly addressing any concerns.

- After-Sales Service: Our support extends beyond delivery, offering assistance with any operational or maintenance questions that may arise over the product's long lifespan.

Concluding Thoughts: The Enduring Value of Specialized Grating

The demand for high-performance industrial materials continues to grow, driven by stricter safety regulations, the need for enhanced operational efficiency, and the increasing complexity of infrastructure projects. Customized Size Hot DIP Galvanized Stainless Steel Grating for Structure Walkway stands as a testament to this evolution, offering a sophisticated solution that marries the inherent corrosion resistance of stainless steel with the robust protection of hot-dip galvanization. Its ability to be precisely tailored to specific project requirements, coupled with a manufacturing process that adheres to stringent international standards, ensures a product that is not only safe and durable but also cost-effective over its extensive lifecycle.

As industries like petrochemical, marine, and water treatment continue to expand and modernize, the reliance on such specialized materials will only intensify. Investing in high-quality, customized grating solutions from reputable manufacturers is not merely a procurement decision; it is a strategic investment in the long-term safety, efficiency, and sustainability of critical infrastructure. The documented advantages in reduced maintenance, extended lifespan, and superior performance underscore its value proposition in today's demanding industrial landscape.

References and Further Reading:

- Grand View Research. (2023). Metal Grating Market Size, Share & Trends Analysis Report. Retrieved from: https://www.grandviewresearch.com/industry-analysis/metal-grating-market

- ASTM International. (2020). ASTM A123/A123M - Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. Retrieved from: https://www.astm.org/a0123_a0123m.htm

- NAAMM. (2009). Metal Bar Grating Manual (MBG 531). National Association of Architectural Metal Manufacturers. (Often cited in engineering specifications, though not publicly available without purchase.)

- NACE International. (Various publications). Corrosion Engineering. Relevant articles on duplex systems and stainless steel corrosion. For specific examples, refer to NACE journals. Example topic: "Corrosion Protection of Duplex Stainless Steels."

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.