Bar Grating Cost Understanding Your Options and Budgeting

When it comes to industrial applications and construction projects, bar grating is an essential component for flooring, walkways, drainage covers, and various other uses. Understanding the cost of bar grating is crucial for project managers, architects, and contractors who are tasked with budgeting and procurement. This article delves into the factors that affect bar grating costs, the various types available, and tips for making informed purchasing decisions.

What is Bar Grating?

Bar grating is made by welding together a series of parallel bars, usually composed of steel or aluminum, creating a grid-like structure. It is known for its strength, durability, and open design, which allows for the passage of light, air, and water. These qualities make it an ideal choice for industrial facilities, commercial buildings, and outdoor applications.

Types of Bar Grating

1. Steel Grating This is the most widely used type of bar grating due to its strength and cost-effectiveness. It can be galvanized to resist corrosion and coated to enhance weather resilience.

2. Aluminum Grating This type is lighter than steel but offers less strength. However, aluminum grating is highly resistant to corrosion, making it suitable for harsh environments.

3. Fiberglass Grating This non-metallic alternative is ideal for applications where electrical conductivity is a concern. It’s lightweight, resistant to chemicals, and less likely to corrode.

Factors Affecting Bar Grating Costs

1. Material Choice The type of material significantly impacts cost. Steel grating is generally less expensive than aluminum or fiberglass, but the final price will vary based on market fluctuations in raw materials.

2. Thickness and Load Capacity Thicker grating can support heavier loads, which may increase the cost. When selecting bar grating, it’s essential to consider the intended use to choose an appropriate thickness.

3. Finish Bar grating can be treated with various finishes, such as hot-dip galvanization or powder coating, to enhance durability and corrosion resistance. These treatments add to the overall cost.

4. Customization Off-the-shelf grating is often less expensive than custom options. Custom dimensions or designs may require specialized manufacturing processes, increasing costs.

bar grating cost

5. Shipping and Handling The cost of transporting bar grating from the manufacturer to the construction site should not be overlooked. Larger orders may incur higher shipping fees.

Average Cost Estimates

While costs can vary based on the aforementioned factors, a rough estimate for bar grating is as follows

- Steel Grating Typically ranges from $1.50 to $5.00 per square foot, depending on thickness and type. - Aluminum Grating Usually falls between $3.00 and $10.00 per square foot. - Fiberglass Grating This can cost between $5.00 and $12.00 per square foot.

Budgeting Tips

To ensure that your project stays on track financially, consider the following tips

1. Get Multiple Quotes Consult various suppliers to compare prices, delivery times, and available options. This can help you find the best deal while ensuring quality.

2. Consider Bulk Purchases Buying in bulk can sometimes yield discounts. If your project requires a significant amount of grating, inquire about bulk pricing.

3. Consider Lifecycle Costs While a cheaper option upfront may save money initially, consider the long-term durability and low maintenance costs of more expensive materials.

4. Plan for Future Needs If your project may expand or evolve, purchasing extra grating for future use can save costs in the long run.

Conclusion

Understanding bar grating costs and the factors that influence them is essential for effective project budgeting. By considering materials, load requirements, customization, and supplier options, you can make informed purchasing decisions that fit your project's needs and budget. Always remember that investing in quality materials will ultimately lead to safer and more durable constructions, making the upfront costs worthwhile.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

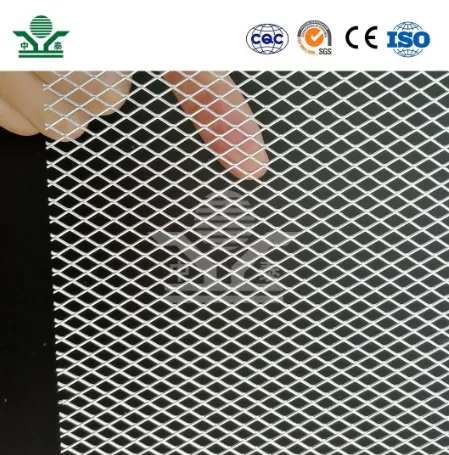

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.