Gen . 21, 2025 04:48

Back to list

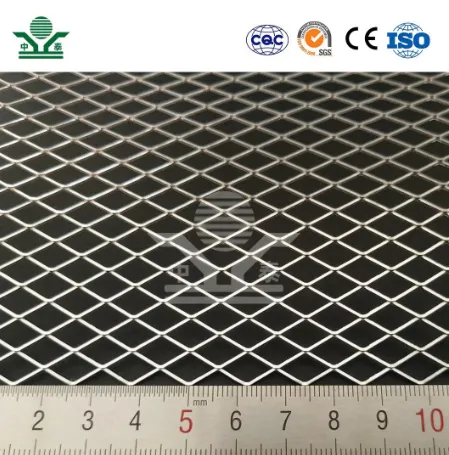

Floor Grating Stainless Steel China Manufacturers Car Grating

Bar grating, an essential component in industrial, commercial, and architectural applications, comes with a variety of cost considerations that are critical for purchasers and specifiers. As an experienced professional in the field of bar grating products, it's essential to navigate these cost variables with a nuanced understanding of the product's applications, material types, manufacturing techniques, and market dynamics to ensure value and performance align with your project's goals.

Market conditions, including fluctuations in raw material prices or changes in demand due to industry trends, also impact pricing. Staying informed about these trends is vital; for instance, a rise in construction activities typically leads to increased demand and potential price hikes for construction materials, including bar grating. Balancing Cost and Quality for Optimal Value While it might be tempting to prioritize low cost, it is crucial to consider the long-term implications of your bar grating choice. Inferior materials or inappropriate manufacturing processes can lead to increased maintenance costs and even safety risks. Therefore, the expertise in specifying a product that balances cost with durability, load capacity, and environmental resistance can result in significant lifecycle savings. Investing in quality, even at a higher upfront cost, ensures reliability and longevity, reducing the frequency of replacements and maintenance interventions. Trustworthy suppliers can offer warranty or guarantee options, enhancing the value proposition for high-quality products. Conclusion Aligning Cost with Project Success The cost of bar grating is a multifaceted issue that requires careful consideration of various technical and market factors. By leveraging professional expertise and understanding these cost elements, purchasers can make informed decisions that align their project's financial constraints with performance needs. Ultimately, strategic sourcing, attention to material and manufacturing quality, and a comprehension of market dynamics empower organizations to optimize their investment in bar grating and ensure long-term project success.

Market conditions, including fluctuations in raw material prices or changes in demand due to industry trends, also impact pricing. Staying informed about these trends is vital; for instance, a rise in construction activities typically leads to increased demand and potential price hikes for construction materials, including bar grating. Balancing Cost and Quality for Optimal Value While it might be tempting to prioritize low cost, it is crucial to consider the long-term implications of your bar grating choice. Inferior materials or inappropriate manufacturing processes can lead to increased maintenance costs and even safety risks. Therefore, the expertise in specifying a product that balances cost with durability, load capacity, and environmental resistance can result in significant lifecycle savings. Investing in quality, even at a higher upfront cost, ensures reliability and longevity, reducing the frequency of replacements and maintenance interventions. Trustworthy suppliers can offer warranty or guarantee options, enhancing the value proposition for high-quality products. Conclusion Aligning Cost with Project Success The cost of bar grating is a multifaceted issue that requires careful consideration of various technical and market factors. By leveraging professional expertise and understanding these cost elements, purchasers can make informed decisions that align their project's financial constraints with performance needs. Ultimately, strategic sourcing, attention to material and manufacturing quality, and a comprehension of market dynamics empower organizations to optimize their investment in bar grating and ensure long-term project success.

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP