Product Description

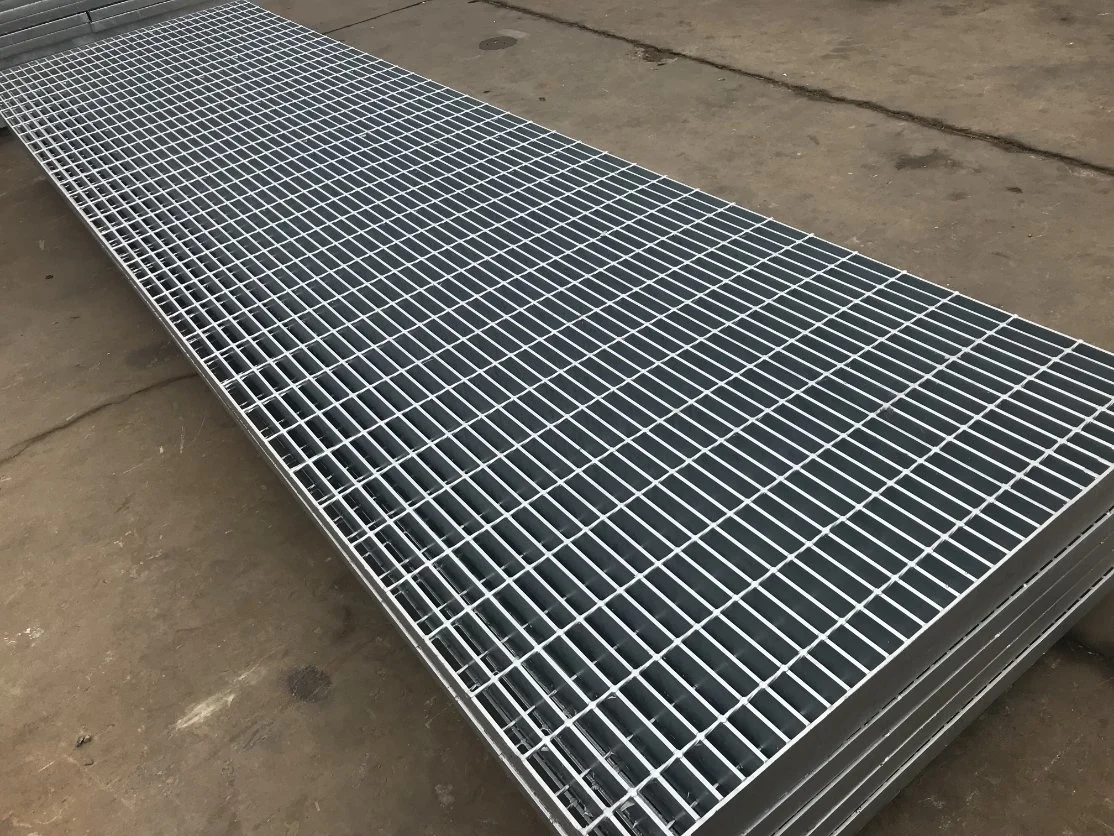

Application:Steel Structure Walkway, Foot Pedal, Drain Cover

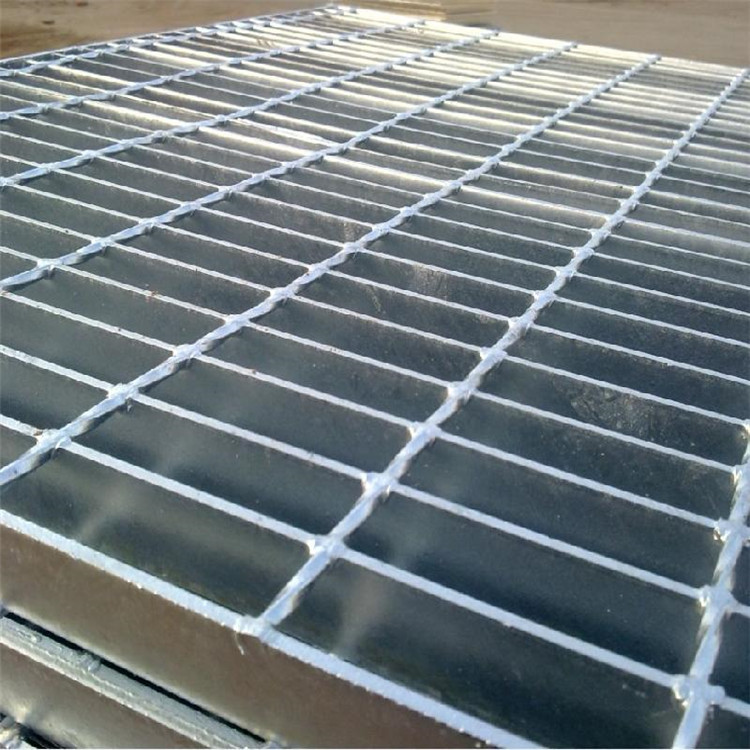

Shape:Flat Shape

Manufacturing Method:Machine Welding

Material:Carbon Steel

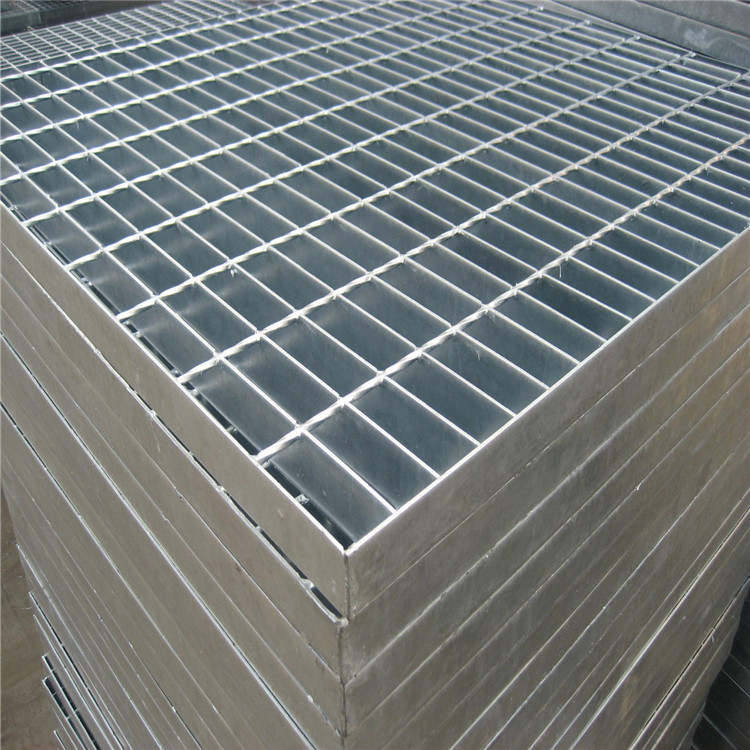

Transport Package:Steel Belt

Specification:all kinds

Origin:Anping, China

HS Code:7314500000

Production Capacity:10000m2/One Day

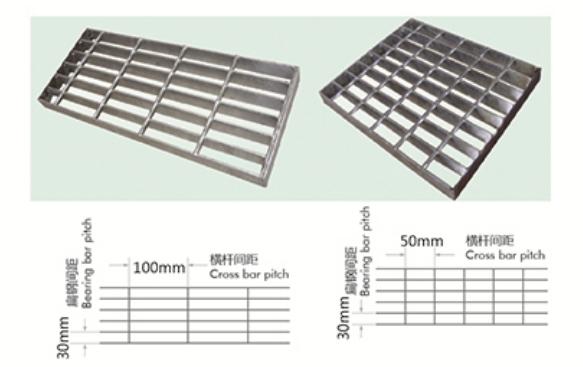

MOST-POPULAR SPECIFICATIONS OF STEEL GRATING

|

The grating with the pitch of 30mm between bearing bars is themost widely used type in industrial field. Among normal types, ihas the strongest resistance to surface lash. |

|

|

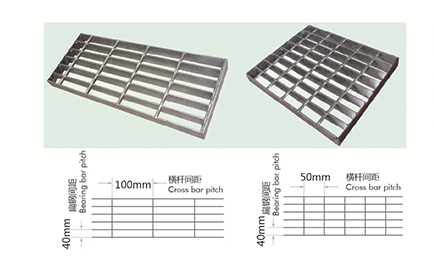

The grating with the pitch of 40mm between bearing bars is themost economical and lightest type. lt is the best choice for you oroccasions that the span is small. |

|

|

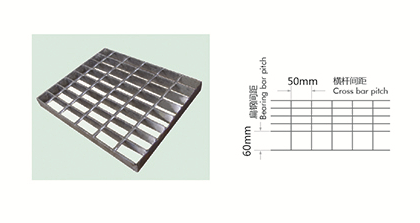

The grating with the pitch of 60mm between bearing bars and the pitch of 50mm between the cross bars is developed specially for mining industry, it solved the problem of mineral splash on the plate .So it is often appointed to use in processing works of mining industry. |

|

|

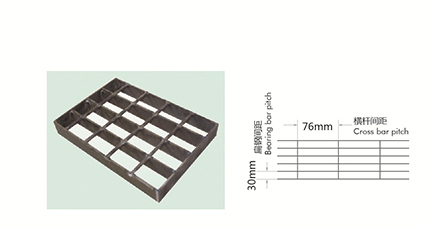

The qrating with the pitch of 30mm between bearing bars and o76mm between cross bars is the most popular iype used at homand abroad, it is proper for many applications such as walkway platforms, etc. |

|

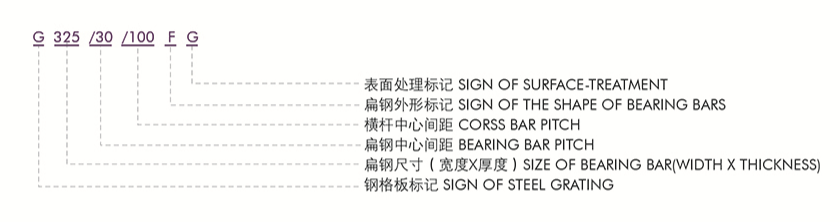

SYMBOL OF STEEL GRATING:

NOTE:

1、Bearing bar pitchesmay be 15,22,25,30, 32.5,34, 40,50,60,80,90mnof which 25,30,34 and 40mm are recommended

2、Cross bar pitches maybe 24-200mm,of which 50mm,7ómm and 100mm are recommended.

3、Sign of the shape of bearing bars:F-Plain style(may be committed in the symbol of steel grating)S-Serrated style

1-|-section style

4. Sign of surface-treatment;G-Hot dipped galvanized,mitted in the symbol of steel grating)may be

U-Untreated

MANUFACTURING PROCESS:

Steel grating is made by the world first-calss Italian ORSOGRIL equipment,which can arrange the bearing bar and cross bar in longitude and latitude order to certain distance. Cross bar is pressed into the bearing bar by high tension resistance welding which is contolled by computer. So we can produce high quality gratings with firm welding, smooth surface and high strength.

CALCULATION OF WEIGHT AND AREA:

1、The weight of gratings varies after end welded and hot galvanizing process. For normal industrial platform using 30mm pitch bearing bars ,the weight will increase 12%; 14% for 40mm pitch bearing bars and 1 6% for 60mm pitch bearing bars.

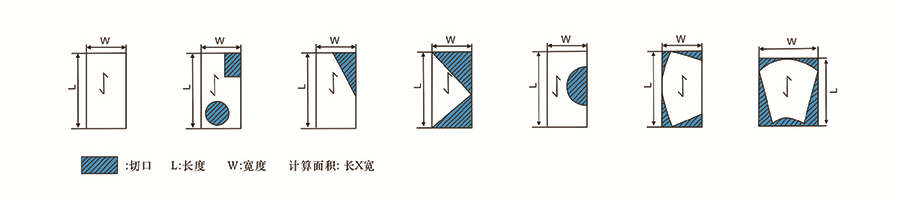

2、For those gratings processed according to the sie aupplied by customer, calculation will be based on the actual ared(includ-ing cutout and tap)

3、For those gratings processed according to customer's drawing, calculation will be based on the total outside sizelincluding

cutout and tap)

4、For unusual size of gratings cutouts shall not deduct from the length and width.

Detailed Photos