फरवरी . 20, 2025 13:50

Back to list

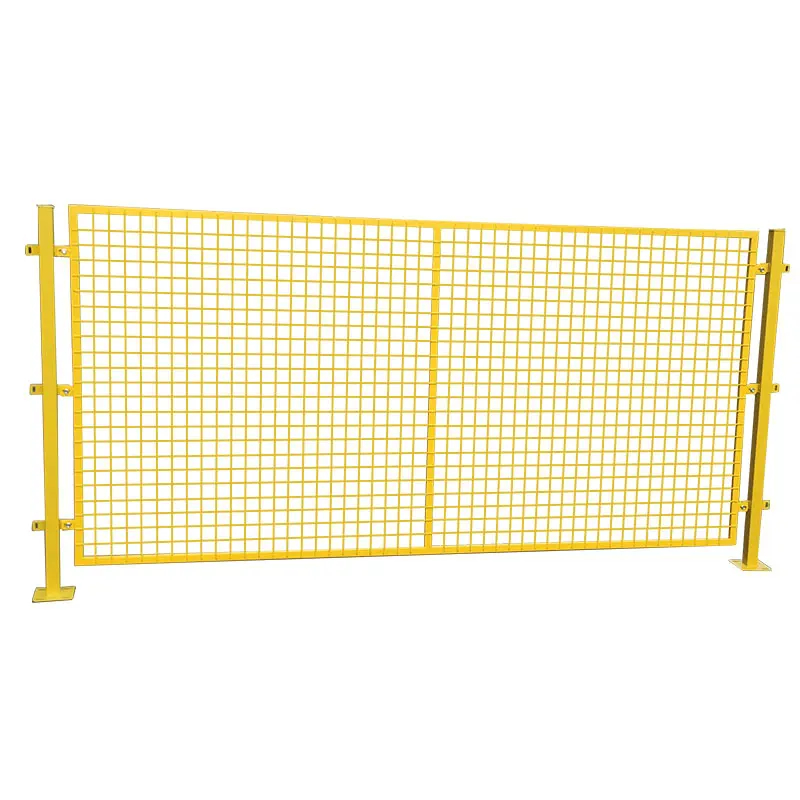

Zhongtai Grate Grill China Wholesalers Galvanized Trench Grates

When considering noise barriers for a project, understanding the pricing intricacies can greatly influence the decision-making process. As experts in the field of sound management, we frequently encounter clients seeking a blend of cost-effectiveness, durability, and performance. Here's an exploration into what affects the price of noise barriers and how to make an informed purchase that aligns with your project objectives.

Maintenance considerations are also paramount in assessing long-term costs associated with noise barriers. Some materials demand more frequent inspections and repairs, which could be both a financial and logistical burden. Opting for low-maintenance solutions can yield savings over the barrier's lifespan and minimize operational disruptions. Moreover, the strategic incorporation of innovative technologies and materials can influence both immediate and future costs. For instance, using advanced sound-absorptive technologies can result in slimmer structures that use less material, thus reducing costs without compromising on performance. Similarly, integrating solar panels or vegetation into noise barriers not only contributes to sustainability but can also open avenues for financial incentives or energy cost savings. In terms of authority and expert recommendations, consulting with acoustical engineers during the planning stages ensures that the barriers meet desired decibel reduction targets. These professionals can offer insight into material choices and installation techniques that harmonize with the project’s acoustic, aesthetic, and budgetary goals. Finally, transparency and trustworthiness in supplier selections cannot be overstated. Partnering with reputable manufacturers who offer warranties and client testimonials adds a layer of assurance in terms of product quality and company reliability. Evaluating suppliers based on their track records and client feedback helps mitigate risks associated with subpar materials or unreliable delivery timelines. In summary, the price of noise barriers is dictated by a myriad of variables, each contributing to their overall cost-effectiveness and performance. By comprehensively evaluating material options, customization needs, installation challenges, and geographical factors, clients can make informed decisions that balance their budget constraints with the desired functional and aesthetic outcomes. Engaging with industry experts, like acoustical engineers and trusted manufacturers, further solidifies the pathway to a successful noise barrier implementation, reflecting both investment prudence and performance efficacy.

Maintenance considerations are also paramount in assessing long-term costs associated with noise barriers. Some materials demand more frequent inspections and repairs, which could be both a financial and logistical burden. Opting for low-maintenance solutions can yield savings over the barrier's lifespan and minimize operational disruptions. Moreover, the strategic incorporation of innovative technologies and materials can influence both immediate and future costs. For instance, using advanced sound-absorptive technologies can result in slimmer structures that use less material, thus reducing costs without compromising on performance. Similarly, integrating solar panels or vegetation into noise barriers not only contributes to sustainability but can also open avenues for financial incentives or energy cost savings. In terms of authority and expert recommendations, consulting with acoustical engineers during the planning stages ensures that the barriers meet desired decibel reduction targets. These professionals can offer insight into material choices and installation techniques that harmonize with the project’s acoustic, aesthetic, and budgetary goals. Finally, transparency and trustworthiness in supplier selections cannot be overstated. Partnering with reputable manufacturers who offer warranties and client testimonials adds a layer of assurance in terms of product quality and company reliability. Evaluating suppliers based on their track records and client feedback helps mitigate risks associated with subpar materials or unreliable delivery timelines. In summary, the price of noise barriers is dictated by a myriad of variables, each contributing to their overall cost-effectiveness and performance. By comprehensively evaluating material options, customization needs, installation challenges, and geographical factors, clients can make informed decisions that balance their budget constraints with the desired functional and aesthetic outcomes. Engaging with industry experts, like acoustical engineers and trusted manufacturers, further solidifies the pathway to a successful noise barrier implementation, reflecting both investment prudence and performance efficacy.

Latest news

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP