फरवरी . 11, 2025 19:19

Back to list

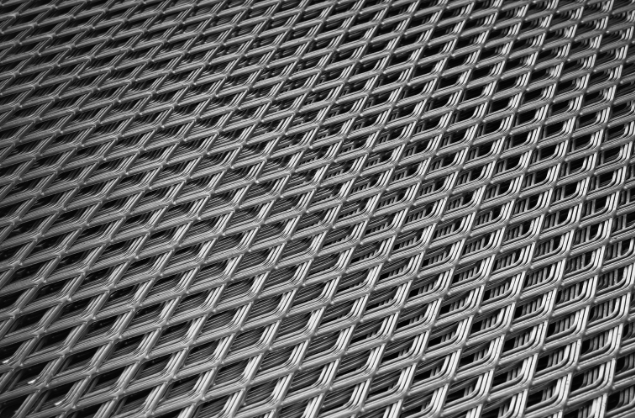

304 perforated stainless steel

Perforated stainless steel, specifically the 304 variety, has carved a niche for itself across multiple industries due to its exceptional combination of strength, versatility, and longevity. This material showcases a series of evenly distributed holes that contribute not only to its aesthetic appeal but also to its functional capacities, making it ideal for an array of applications.

Environmental sustainability is an additional aspect where 304 perforated stainless steel demonstrates its trustworthiness. The material is 100% recyclable, which mitigates environmental impact and aligns with global sustainability goals. Its long lifecycle further reduces the need for frequent replacements, ensuring resource conservation and lessening waste. Beyond its product-centric benefits, trust in 304 perforated stainless steel is bolstered by its rigorous compliance with global industry standards. Organizations such as ASTM International and the International Organization for Standardization (ISO) provide stringent guidelines that govern its production, ensuring consistent quality and performance. Customers can rely on this standardization as a testament to its safety and reliability. Experts cite its thermal properties as another advantage, making it suitable for high-temperature applications. Commercial kitchen equipment manufacturers often select 304 perforated stainless steel for oven and range components due to its ability to withstand extreme heat without warping or suffering damage. This specialized competence guarantees that end products meet rigorous operational demands while maintaining food safety standards. The adaptability of 304 perforated stainless steel extends to its ease of maintenance and cleaning. Its smooth surface inhibits bacterial proliferation, which is critical in hygienic applications like medical device sterilization trays and pharmaceutical equipment. This proficiency in maintaining sterile conditions underpins its authoritative status in healthcare environments. In conclusion, 304 perforated stainless steel stands out as a formidable material choice across diverse sectors due to its unparalleled combination of durability, adaptability, and aesthetic value. Embracing both practical and innovative applications, it continues to dominate as a go-to solution for professionals seeking reliability and excellence in product design. From construction to engineering, its proven track record substantiates its role as an industry staple, ensuring practitioners can count on its virtually limitless potential.

Environmental sustainability is an additional aspect where 304 perforated stainless steel demonstrates its trustworthiness. The material is 100% recyclable, which mitigates environmental impact and aligns with global sustainability goals. Its long lifecycle further reduces the need for frequent replacements, ensuring resource conservation and lessening waste. Beyond its product-centric benefits, trust in 304 perforated stainless steel is bolstered by its rigorous compliance with global industry standards. Organizations such as ASTM International and the International Organization for Standardization (ISO) provide stringent guidelines that govern its production, ensuring consistent quality and performance. Customers can rely on this standardization as a testament to its safety and reliability. Experts cite its thermal properties as another advantage, making it suitable for high-temperature applications. Commercial kitchen equipment manufacturers often select 304 perforated stainless steel for oven and range components due to its ability to withstand extreme heat without warping or suffering damage. This specialized competence guarantees that end products meet rigorous operational demands while maintaining food safety standards. The adaptability of 304 perforated stainless steel extends to its ease of maintenance and cleaning. Its smooth surface inhibits bacterial proliferation, which is critical in hygienic applications like medical device sterilization trays and pharmaceutical equipment. This proficiency in maintaining sterile conditions underpins its authoritative status in healthcare environments. In conclusion, 304 perforated stainless steel stands out as a formidable material choice across diverse sectors due to its unparalleled combination of durability, adaptability, and aesthetic value. Embracing both practical and innovative applications, it continues to dominate as a go-to solution for professionals seeking reliability and excellence in product design. From construction to engineering, its proven track record substantiates its role as an industry staple, ensuring practitioners can count on its virtually limitless potential.

Latest news

-

Trusted Expanded Metal Mesh For All Projects

NewsMay.08,2025

-

Stainless Steel Expanded Metal for Versatile Uses

NewsMay.08,2025

-

Reliable Steel Grating Choices

NewsMay.08,2025

-

Perforated Sheet Metal for Every Need

NewsMay.08,2025

-

Heavy Duty Expanded Metal Mesh for Robust Solutions

NewsMay.08,2025

-

Expanded Aluminum Metal for Versatile Applications

NewsMay.08,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP