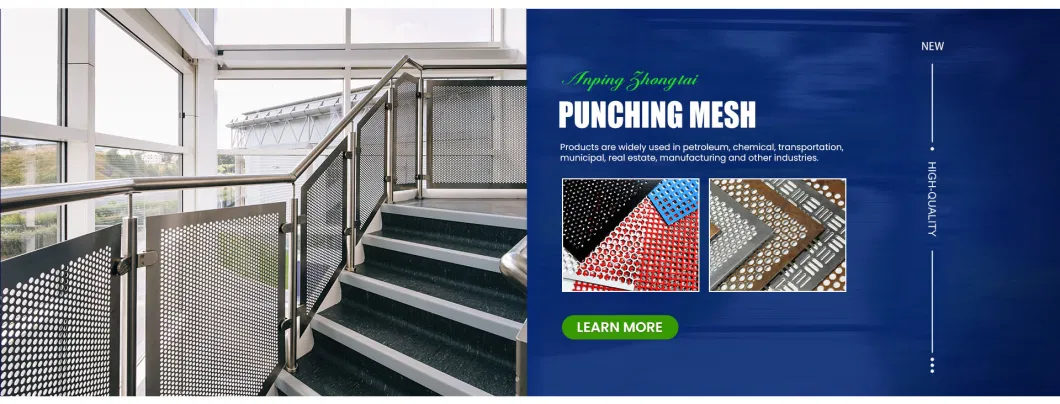

Product Introduction

In order to improve the valuation process and order fulfillment, below we present a specific scope of data that a complete order should contain:

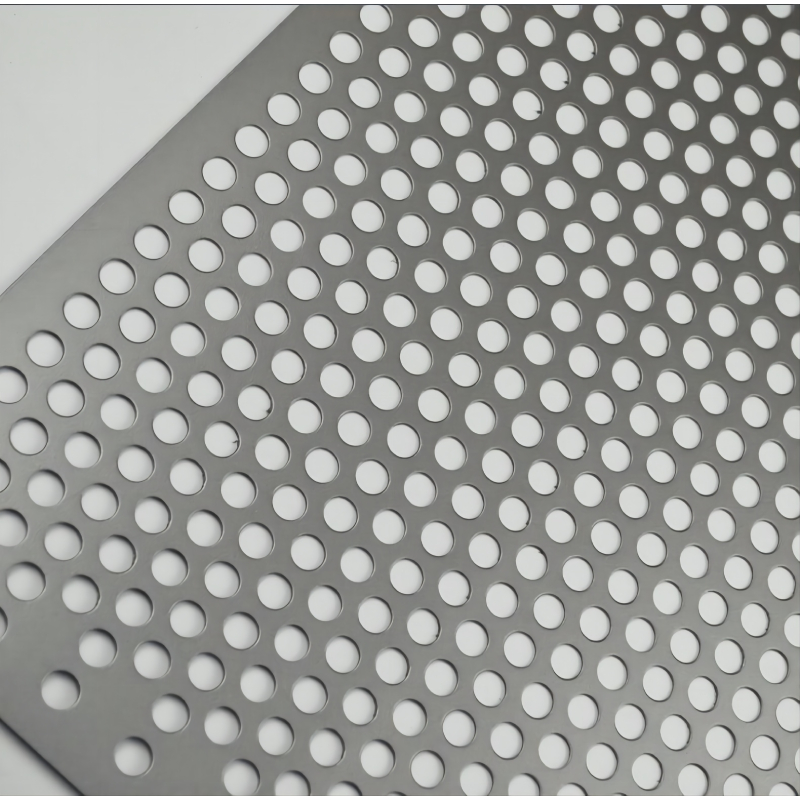

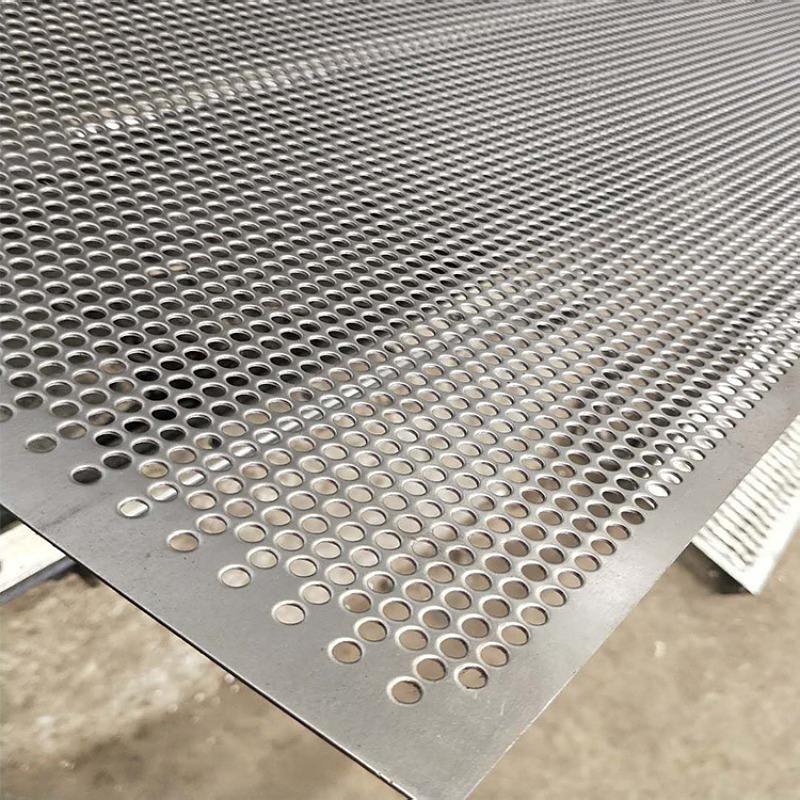

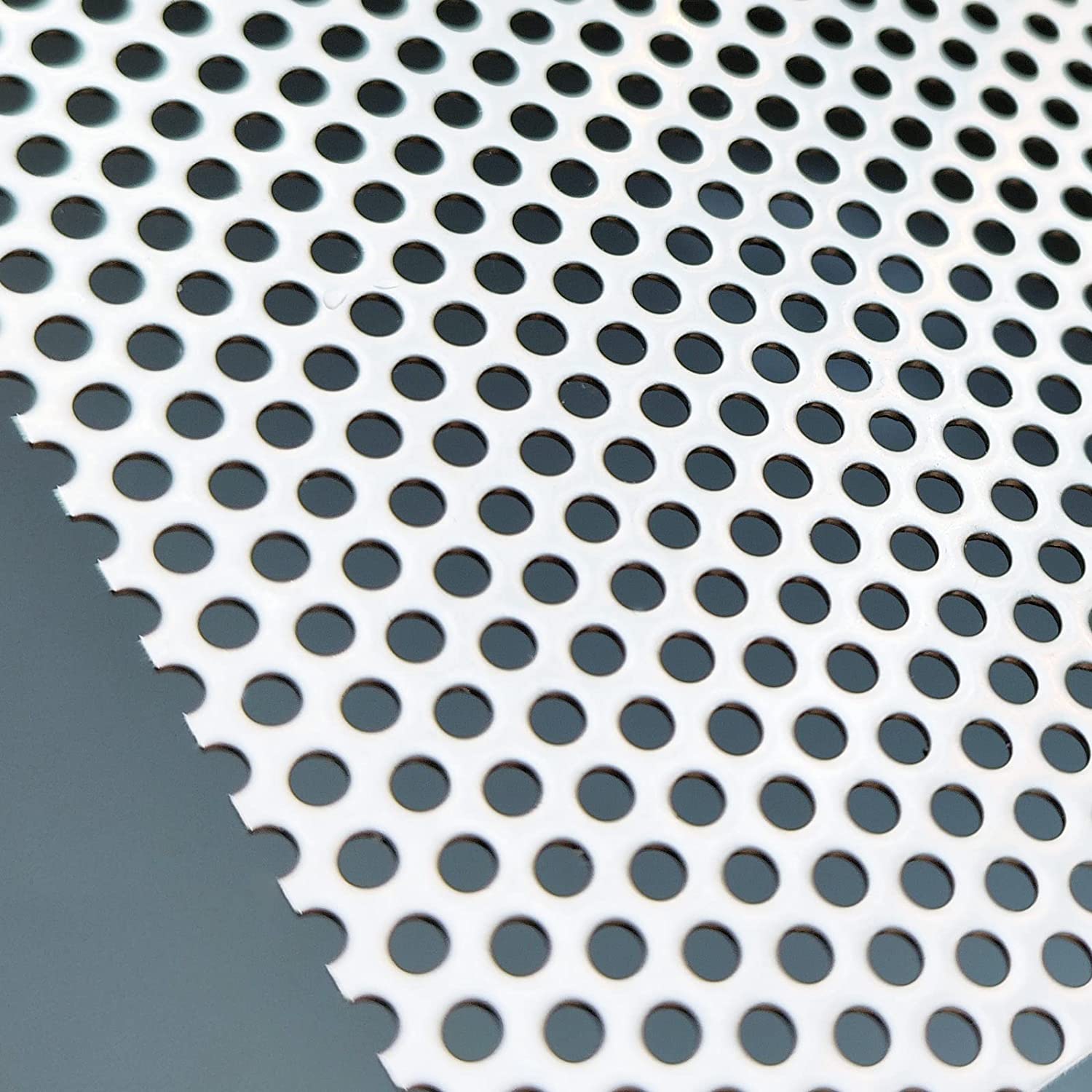

- - The arrangement of meshes (stagger, straight, or otherwise) as well as the distance between the eyelets

- Margins (area without perforation), optionally mark their absence

It would also be helpful if you could specify your needs precisely about the purpose of specific products and specify the expected goods delivery time. Please also pay attention to some key parameters and dependencies that have a significant impact on the final price of the product.

- Type and thickness of the raw material - The cheapest material is steel sheet, however, using more durable materials, you can reduce the thickness to obtain similar strength. It should also be remembered that the thinner material perforates faster.

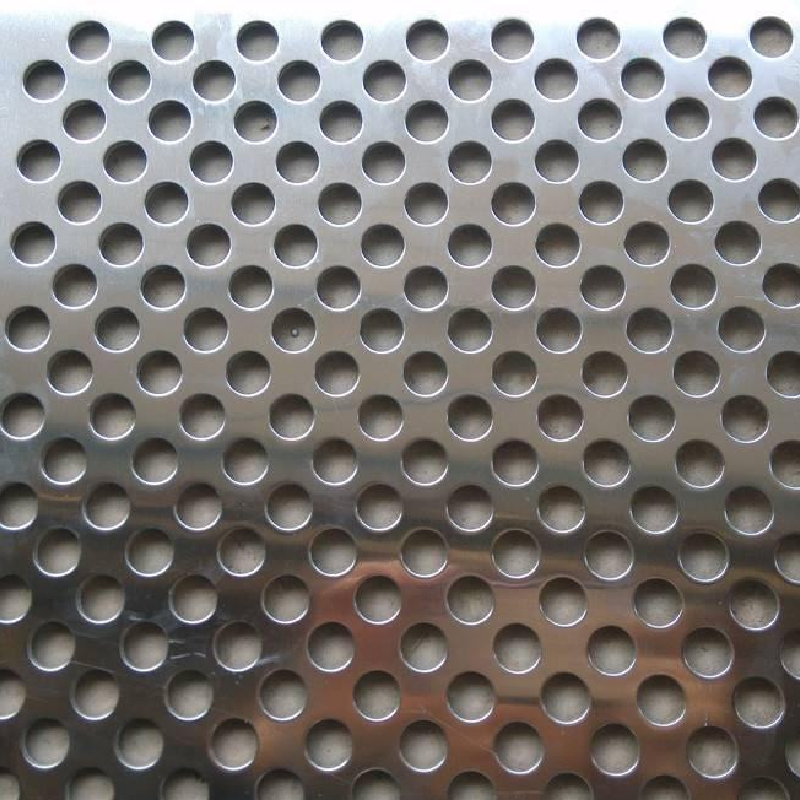

- The size of the holes - the diameter of the hole should not be smaller than the thickness of the material, and preferably if the mesh has a diameter about twice as large as the thickness of the sheet.

Perforated sheets made in accordance with the standards are cheaper and faster in perforation

- The clearance should not exceed 65% so as not to cause distortion.

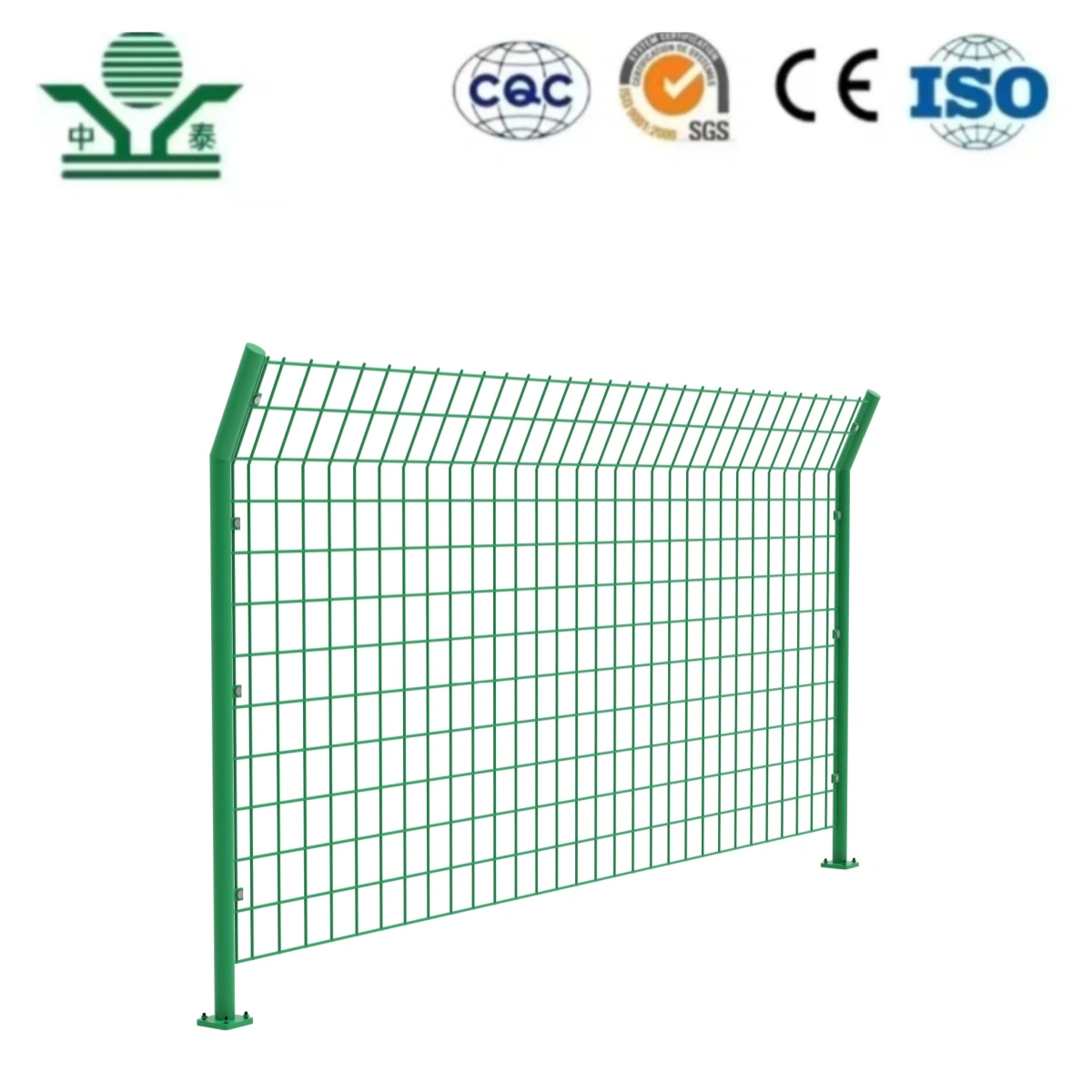

Product Categories

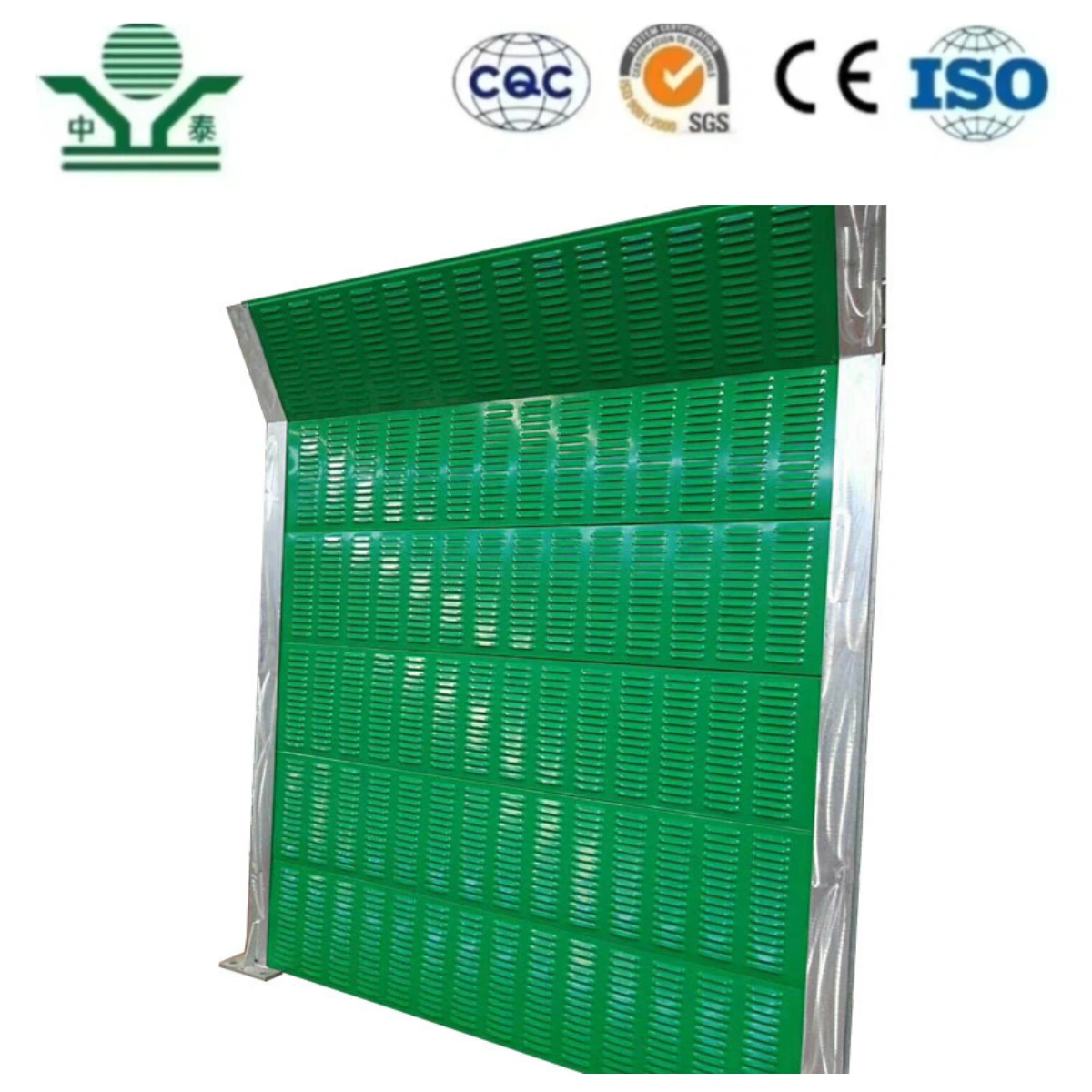

Perforated mesh is also widely used in

- Chemical machinery,

- Pharmaceutical equipment,

- Food and beverage machinery,

- Cigarette machinery, harvesters,

- Dry cleaning machine, ironing table,

- Silencer equipment,

- Refrigeration equipment (central air conditioning)

- Craft making,

- Papermaking,

- Hydraulic accessories,

- Filtration equipment and other industries.

- 01.Technical parameters

Matériel: ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers.

Format:

thickness up to 18 mm, width up to 2.000 mm, length up to 6,000 mm. For some assortments, it is possible to perforate the coils in the coils (coil width Format: up to 1600 mm).

Pour certains types de perforations, il peut y avoir des restrictions sur l'épaisseur et la largeur de la feuille et la nécessité de laisser des marges technologiques non perforées.

Standard operations:

redressage unique, découpe sur mesure et conditionnement sur palettes.

Additional operations:

bending, rolling, pressing, trapezoidal, framing, welding, welding, powder coating, wiping/cleaning with oil, etc.

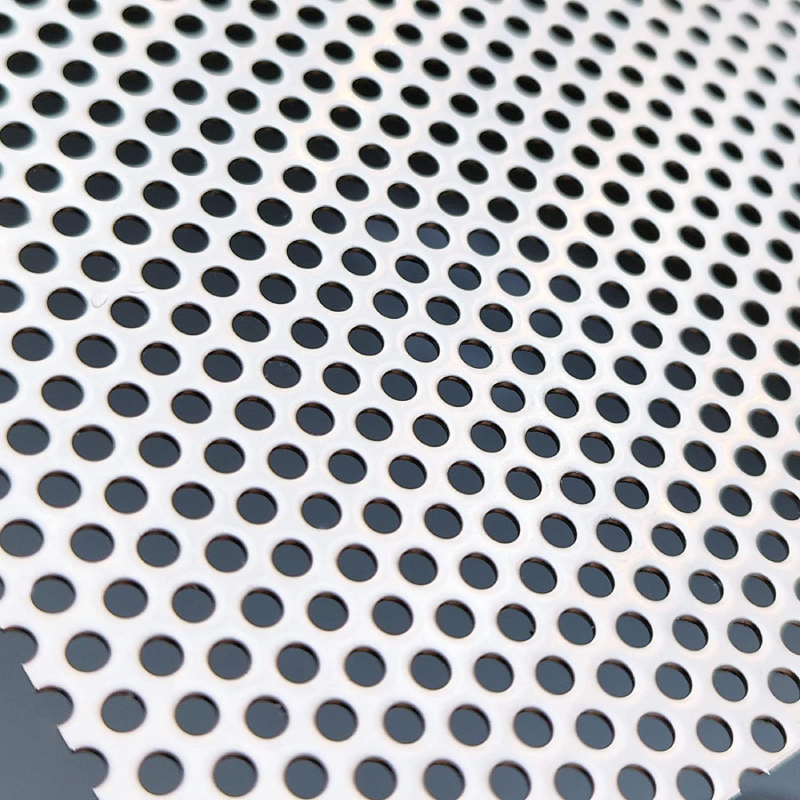

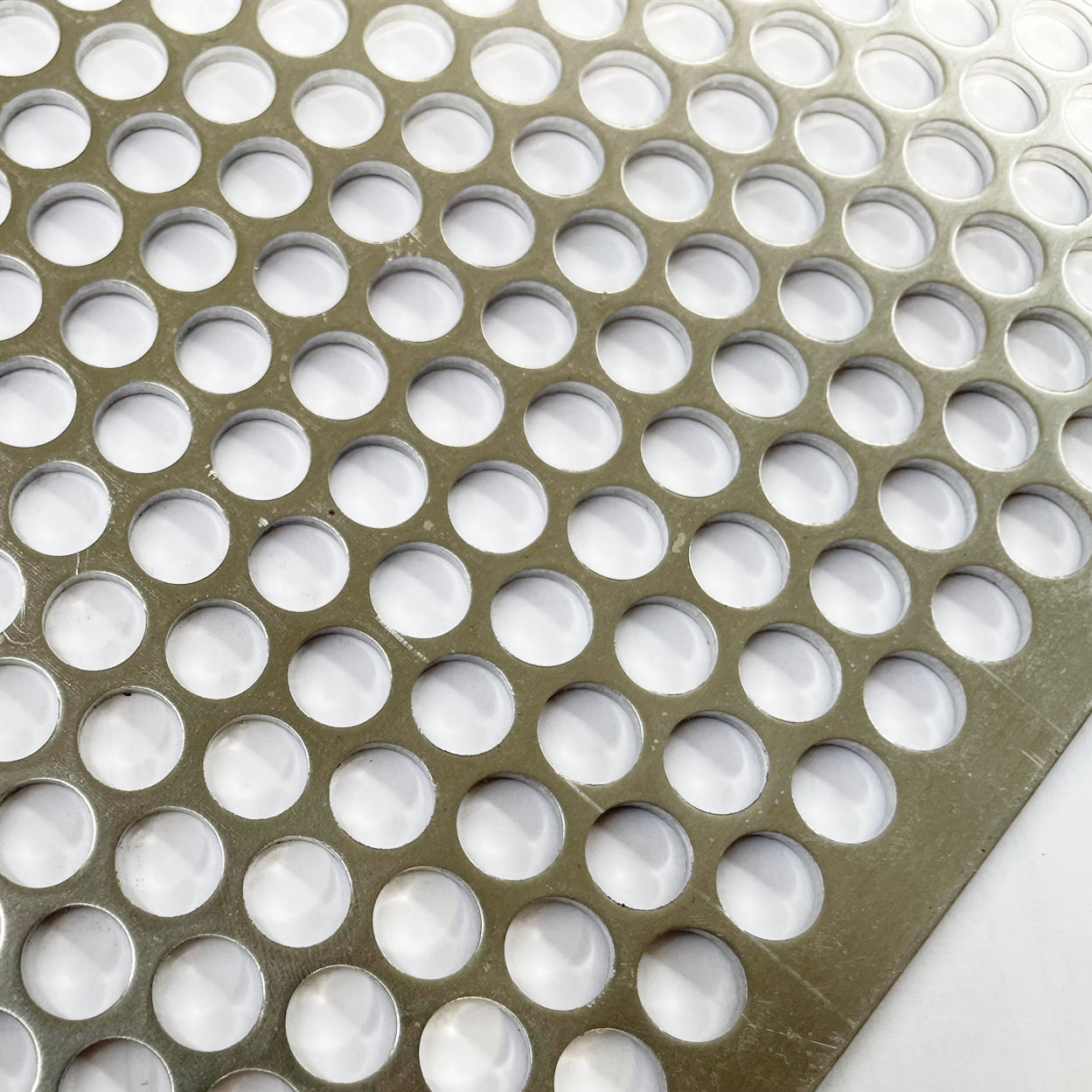

- 02.The structure of the hole

Le trou dans la tôle se compose de trois parties, créées au cours du processus de production :

La structure du trou

1. Zone of dents

2. Cutting zone

3. Extraction area

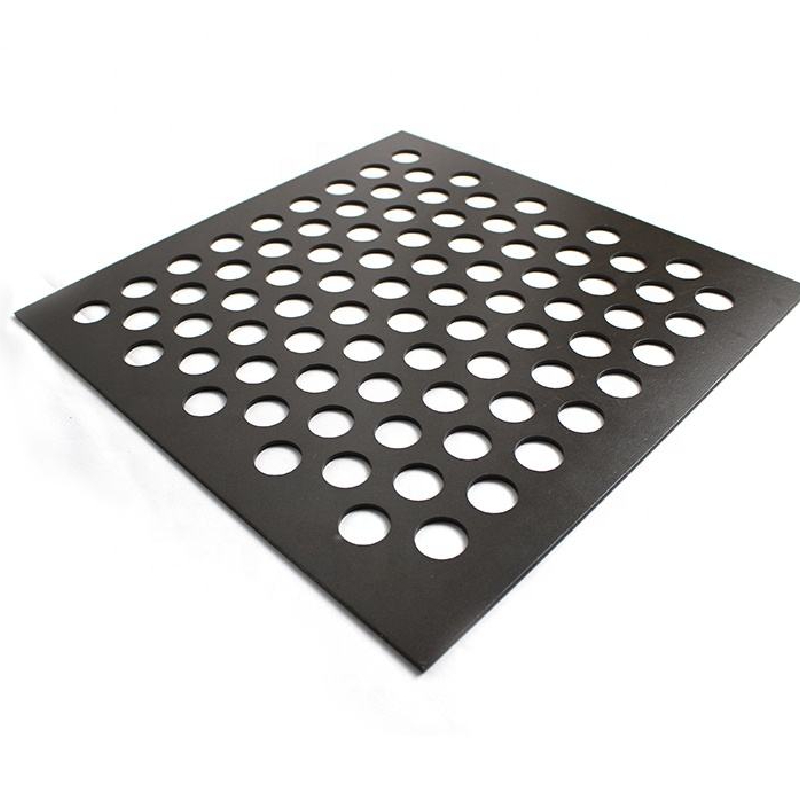

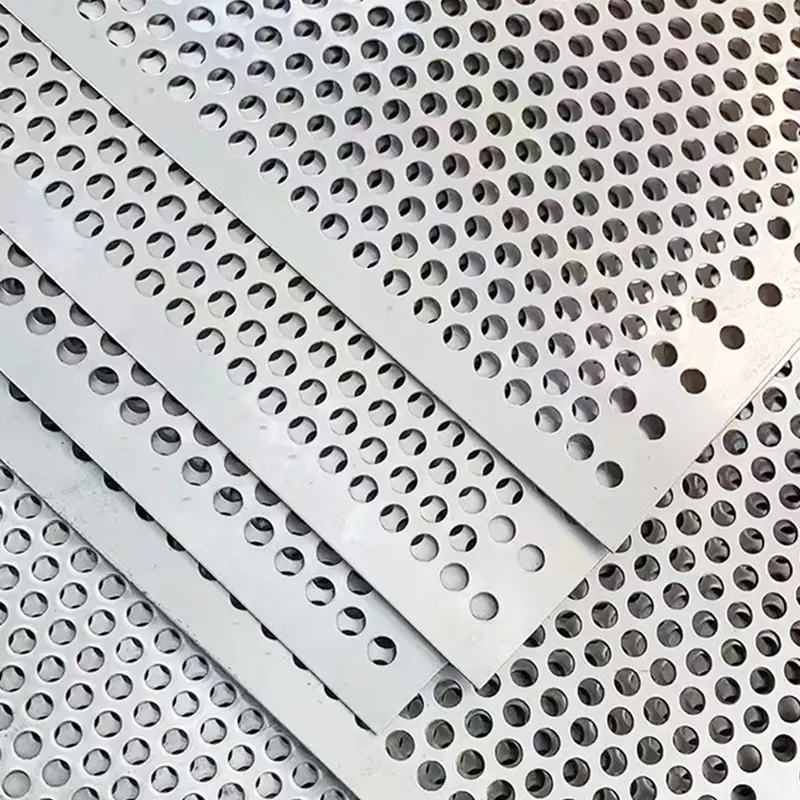

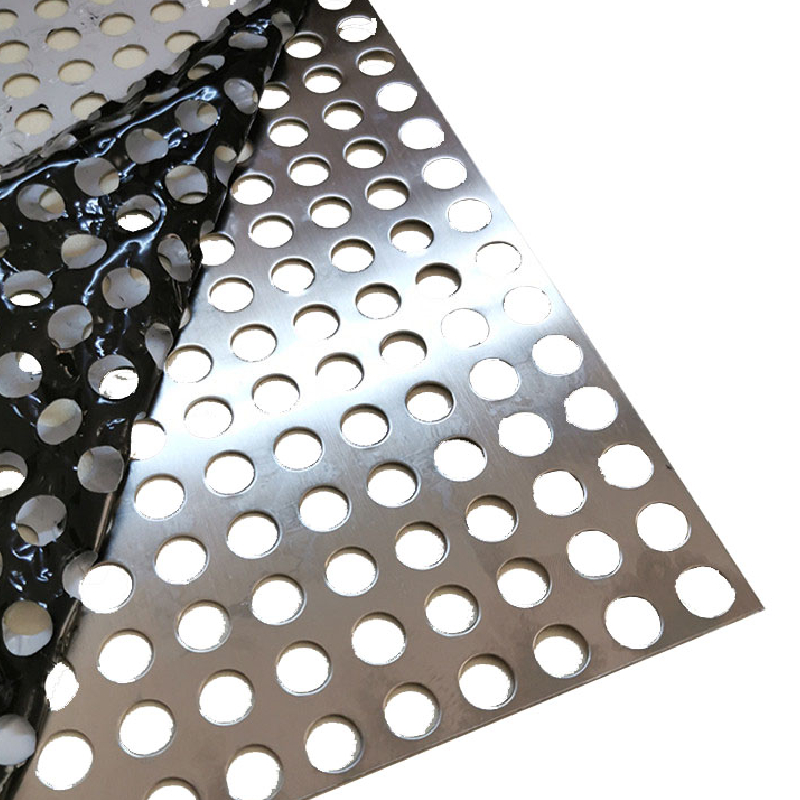

03. Product description

Les feuilles typiques sont produites avec des marges transversales et longitudinales non perforées.

Il existe également la possibilité de perforation selon les dessins du client et les feuilles avec un champ de perforation complet - après consultation. En standard, toutes les feuilles sont redressées après perforation. De plus, nous proposons des services de traitement ultérieur du produit, ce qui permet aux clients d'acheter des composants prêts à l'emploi.

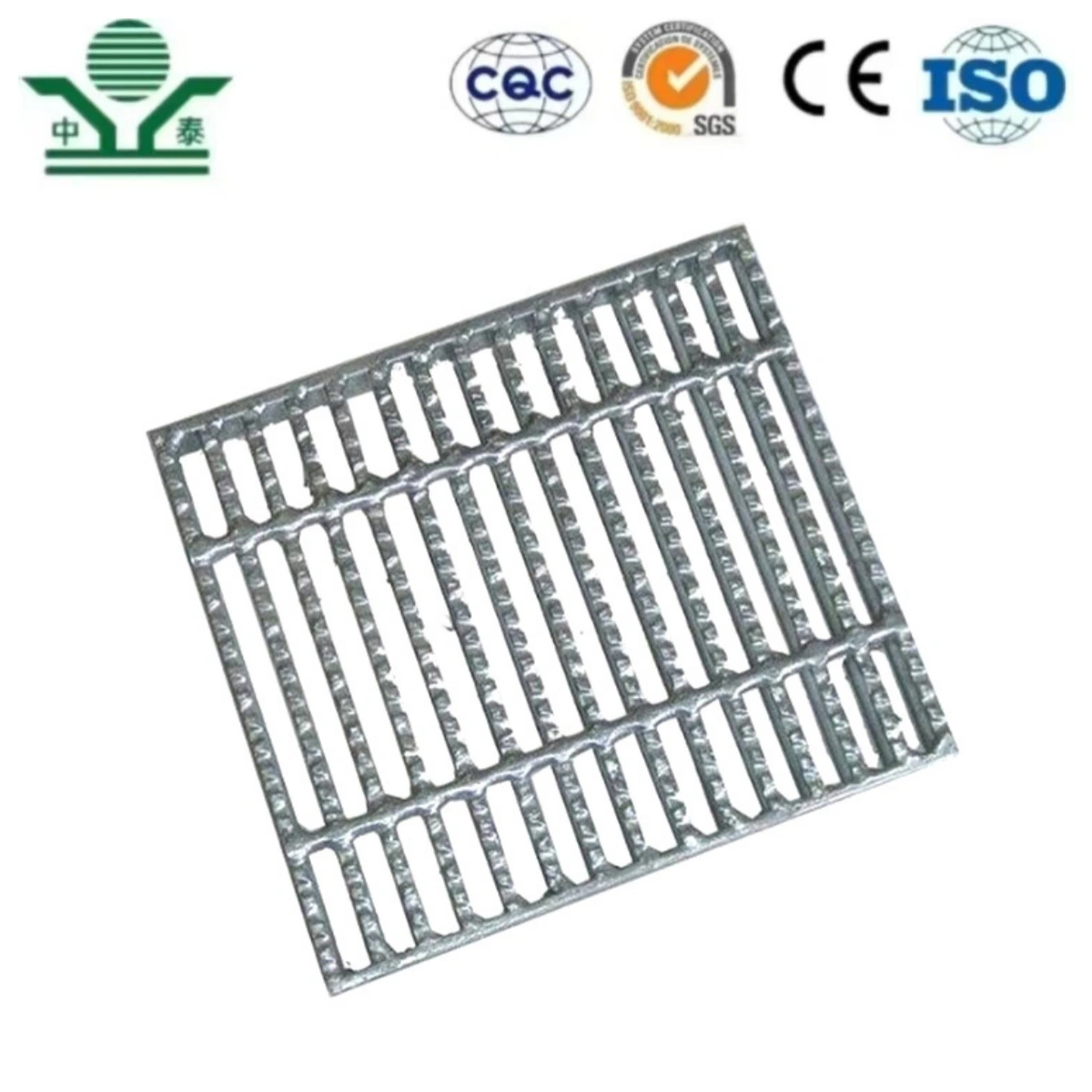

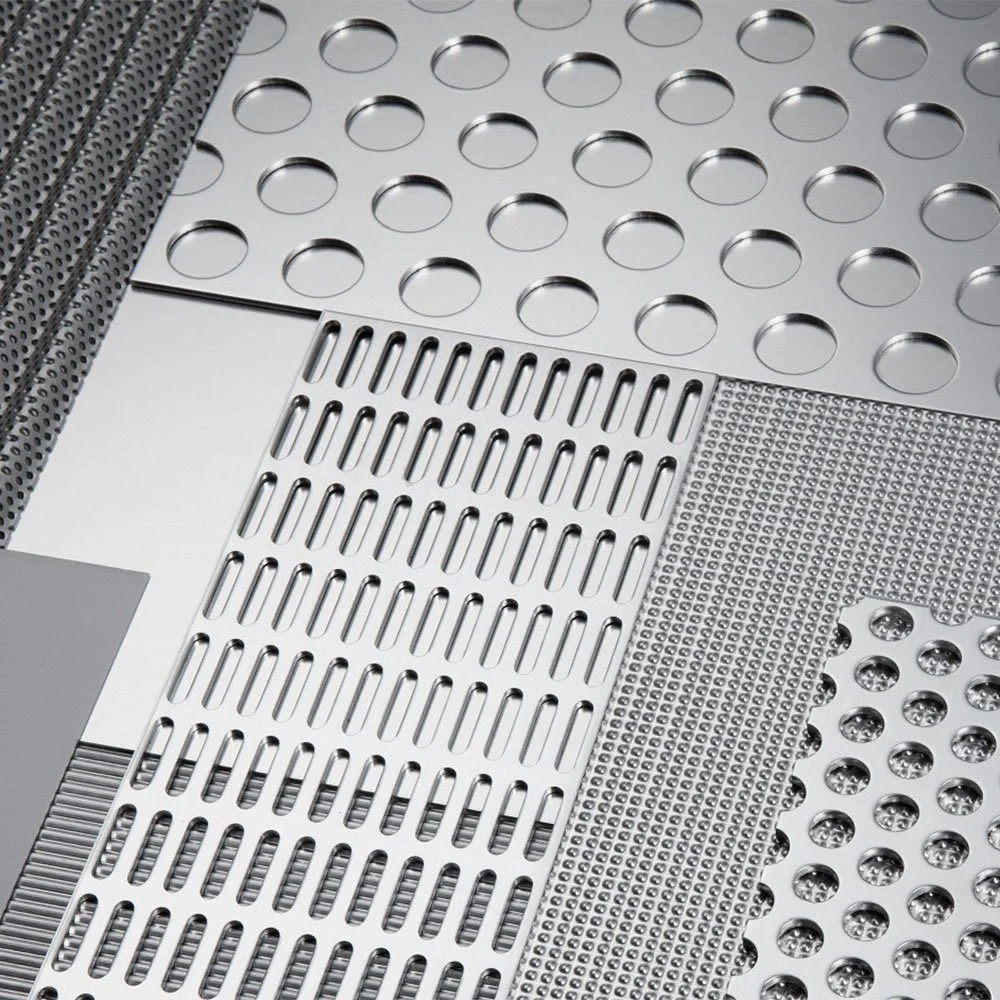

Product Parameters

|

Brand Name |

ZHONGTAI WIRE MESH |

|

Product Name |

Steel Perforated Mesh |

|

Materials |

Stainless steel plate, low carbon steel plate, galvanized plate, PVC plate, cold rolled coil, hot rolled plate, aluminum plate, copper plate, etc. |

|

Hole Shape |

Rectangular Hole, Square Hole, Diamond Hole, Round Hole, Oblong Hole, Hexagonal Hole, Cross Hole, Triangular Hole, Long Waist Hole, Plum Blossom Hole, Fish Scale Hole, Pattern Hole, Eight-Character Net, Herringbone Hole, Five-Pointed Star Hole, Irregular Holes, Bulging Holes, Special-Shaped Holes, Louver Holes, Etc. |

|

Type |

Patterned Perforated Mesh, Formed Perforated Mesh, Heavy-Duty Perforated Mesh, Extra-Thin Perforated Mesh, Micro-Perforated Mesh, Line-Cut Perforated Mesh, Laser Perforated Mesh, Etc. |

|

Specifications |

1. Coiled plate thickness: 0.2mm-1mm, length: 20m. |

|

Color |

Customized |

Detailed Photos