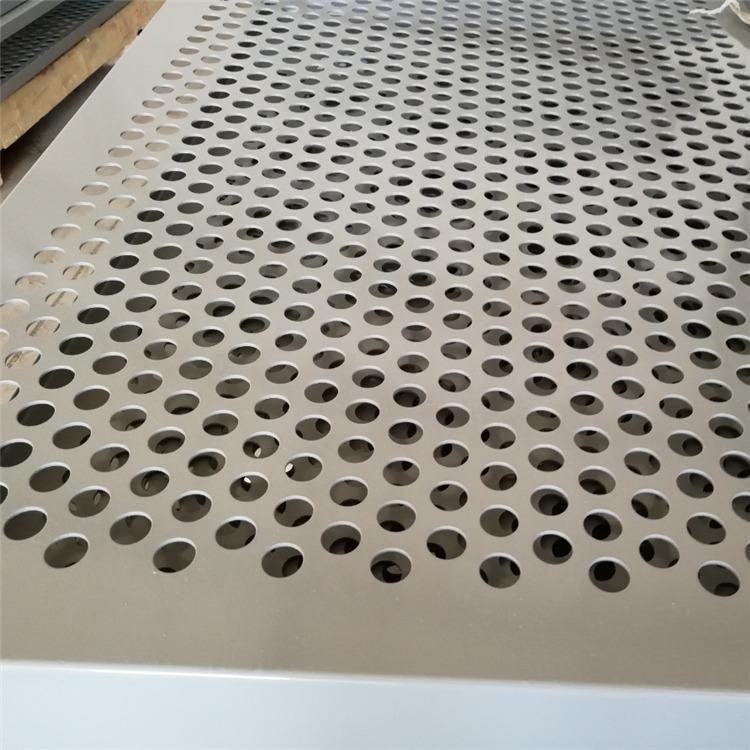

3D Galvanized Steel Perforated Sheets for Durable Fencing Solutions

At Zhangjiagang Tianwei Wire Mesh Co., Ltd., we specialize in providing innovative fencing solutions that combine strength, durability, and aesthetic appeal. Our 3D Galvanized Steel Perforated Metal Sheets are engineered to meet the demanding requirements of modern construction and industrial applications. These sheets offer exceptional resistance to corrosion, making them ideal for both indoor and outdoor fencing projects.

Product Overview

The 3D Galvanized Steel Perforated Metal Sheet is a versatile material designed for fencing applications. Its unique perforated structure enhances structural integrity while allowing for airflow and light penetration. The galvanization process ensures long-term protection against rust and weathering, making it a preferred choice for commercial and residential fencing.

Key Features and Benefits

- Corrosion Resistance: The galvanized coating provides a protective barrier against moisture and environmental elements, significantly extending the product's lifespan.

- Structural Strength: The 3D perforated design enhances load-bearing capacity, ensuring the fencing remains intact under various conditions.

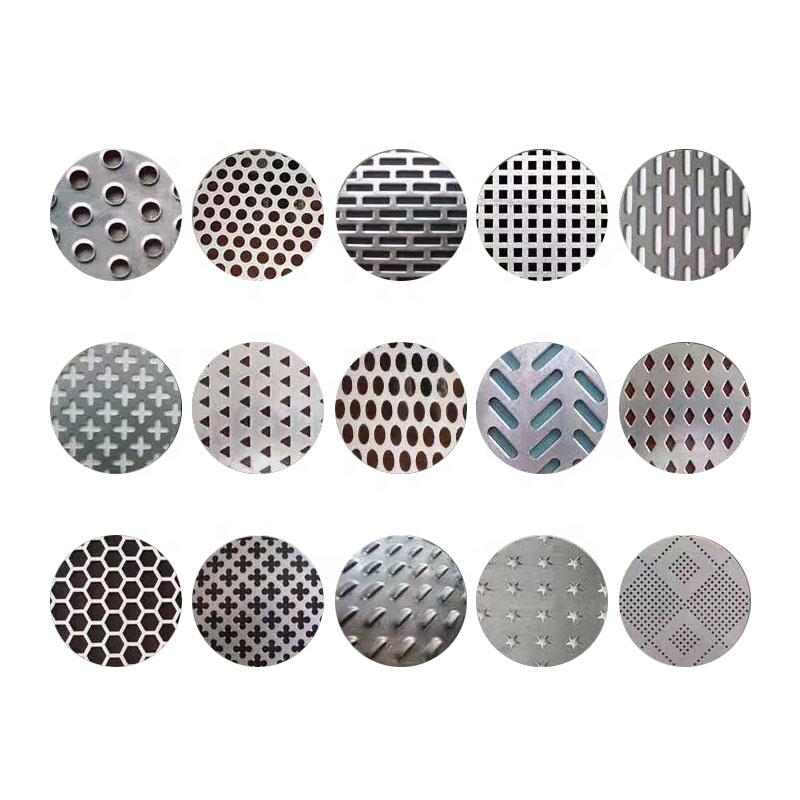

- Customizable Design: Available in multiple patterns and sizes, these sheets can be tailored to suit specific project requirements.

- Cost-Effective: With minimal maintenance needs, these sheets offer long-term cost savings compared to traditional fencing materials.

Applications

Our perforated metal sheets are widely used in various industries, including:

- Industrial fencing for warehouses and factories

- Residential security fencing

- Commercial building perimeter protection

- Greenhouse and agricultural fencing

Market Demand and Industry Pain Points

The demand for durable and low-maintenance fencing solutions has surged in recent years. Traditional materials like wood and untreated steel often face issues such as rot, rust, and structural degradation. Our 3D Galvanized Steel Perforated Sheets address these challenges by offering a robust alternative that maintains its integrity over time. The perforated design also allows for better ventilation, reducing the risk of mold and mildew in humid environments.

Company Expertise and Innovation

Zhangjiagang Tianwei Wire Mesh Co., Ltd. has established itself as a leader in the metal mesh industry, with over a decade of experience in manufacturing high-quality fencing solutions. Our state-of-the-art production facilities and rigorous quality control processes ensure that every product meets international standards.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Galvanized Steel |

| Thickness | 0.8mm - 2.0mm |

| Perforation Pattern | Customizable (e.g., round, square, hexagonal) |

| Surface Finish | Hot-dipped galvanized |

| Dimensions | Customizable to client requirements |

Customer Testimonials

Our clients consistently praise the performance and value of our 3D Galvanized Steel Perforated Sheets. One satisfied customer noted, "The durability and low maintenance of these sheets have significantly reduced our operational costs. They are a perfect solution for our industrial fencing needs."

Implementation and Customization

We offer tailored solutions to meet the unique needs of each client. Whether you require a specific perforation pattern, size, or finish, our team works closely with you to ensure the final product aligns with your project specifications. Our experts provide comprehensive guidance on installation and maintenance to maximize the product's lifespan.

Environmental and Safety Compliance

All our products comply with international environmental and safety standards. The galvanization process is eco-friendly, and the sheets are free from harmful substances, ensuring safe handling and long-term use without compromising environmental integrity.

Shipping and Packaging

Our 3D Galvanized Steel Perforated Sheets are packaged in sturdy, moisture-resistant containers to ensure safe delivery. We offer flexible shipping options to accommodate both small and large orders, with efficient logistics to meet your project timelines.

After-Sales Support

We stand behind our products with comprehensive after-sales support, including technical consultations, installation guidance, and customized solutions. Our dedicated team is always available to address any inquiries or concerns, ensuring a seamless experience from purchase to installation.

Contact Us

For more information about our 3D Galvanized Steel Perforated Sheets or to request a customized quote, please visit our product page or contact us directly at sales@ztwiremesh.com. Discover how our innovative fencing solutions can enhance your projects today!

Frequently Asked Questions (FAQ)

Q: What makes 3D Galvanized Steel Perforated Sheets different from traditional fencing materials?

A: These sheets combine the strength of steel with the corrosion resistance of galvanization, offering a longer lifespan and lower maintenance compared to wood or untreated metal.

Q: Can the perforation patterns be customized?

A: Yes, we offer customizable perforation patterns to suit specific design and functional requirements.

Q: Are these sheets suitable for outdoor use?

A: Absolutely. The galvanized coating ensures resistance to weathering, making them ideal for outdoor applications.

Q: How long does the galvanization process last?

A: With proper maintenance, the galvanized coating can last up to 20 years, depending on environmental conditions.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.