Perforated Steel Sheets with Round Holes Versatility and Applications

Perforated steel sheets are essential in various industries owing to their unique design, functionality, and aesthetic appeal. Among the various patterns available, sheets with round holes stand out due to their versatility and effective functionality. These sheets consist of a flat piece of steel that has been punched with a series of holes, typically arranged in a uniform pattern. The result is a material that provides strength while allowing for ventilation, drainage, and light penetration.

One of the primary advantages of perforated steel sheets with round holes is their lightweight nature. Despite being robust and durable, the perforation process reduces the overall weight of the material without compromising its structural integrity. This makes it an ideal choice for applications where weight is a critical factor, such as in the construction of lightweight structures and enclosures.

Applications Across Industries

Perforated steel sheets are employed across various sectors, each benefiting from the combination of strength and permeability that round hole patterns provide. In the architectural field, these sheets are used for facades, sunshades, and decorative elements. The round holes can create captivating visual effects while allowing natural light and airflow into buildings, hence contributing to energy efficiency and reducing reliance on artificial lighting.

In the manufacturing industry, perforated steel sheets find use as filters, screens, and sound dampening materials. In filtration applications, the size of the round holes can be customized to allow only certain particles to pass through, making these sheets invaluable in environments that require separation, such as water treatment facilities and food processing plants.

The automotive industry also utilizes perforated steel sheets, particularly in the production of exhaust systems and grills. The round holes provide the necessary ventilation while maintaining a sleek design that enhances the vehicle's aesthetics. Moreover, in the electronics sector, these sheets are often incorporated into casings and enclosures for electronic devices, allowing for proper heat dissipation while protecting internal components.

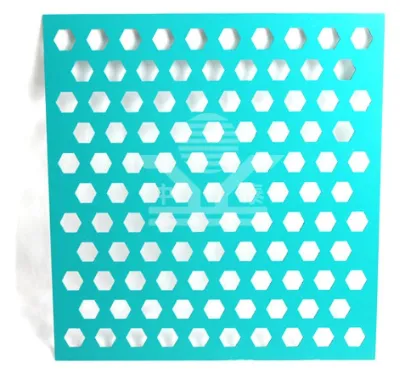

perforated steel sheet round holes

Aesthetic Appeal and Customization

Beyond their functional applications, perforated steel sheets with round holes have gained popularity in the design world due to their aesthetic appeal. Designers and architects often leverage the visual characteristics of these sheets to create striking installations and interiors. With advancements in technology, manufacturers can now offer extensive customization options, including different hole sizes, spacing, and sheet dimensions. This adaptability ensures that clients can achieve the desired look and functionality for their projects.

Durability and Maintenance

Another significant advantage of using perforated steel sheets is their durability. Typically made from high-quality steel, these sheets are resistant to rust and wear, especially when treated with protective coatings such as powder coating or galvanization. This ensures a long service life, even in harsh environments. Maintenance is also straightforward; regular cleaning and inspection are usually sufficient to keep the material in optimal condition.

Conclusion

Perforated steel sheets with round holes represent a perfect blend of strength, functionality, and aesthetic appeal. Their wide-ranging applications across various industries highlight their versatility as a material. As technology progresses and the demand for customized designs increases, perforated steel sheets will continue to be a preferred choice for architects, engineers, and manufacturers alike. Whether for practical applications in filtration and construction or innovative designs in architecture, these sheets are poised to remain a staple in modern design and engineering.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.