The Versatility and Benefits of Welded Steel Grating

Welded steel grating is a widely used product in various industrial and commercial applications, renowned for its strength, durability, and versatility. Fabricated from high-quality steel bars, this type of grating is designed by welding the cross bars to the main bearing bars at their intersections, creating a robust mesh-like structure that offers numerous benefits. This article delves into the features, advantages, and applications of welded steel grating.

Features of Welded Steel Grating

Welded steel grating typically consists of horizontal bearing bars and vertical cross bars. The spacing between these bars can be customized, making it suitable for various load requirements and environmental conditions. The manufacturing process involves high temperatures and pressure, ensuring a strong bond and a product that can withstand significant physical stresses. Available in different sizes and load capacities, welded steel grating can be tailored to meet specific needs, from light-duty applications to heavy industrial usage.

Advantages of Welded Steel Grating

One of the primary advantages of welded steel grating is its exceptional durability

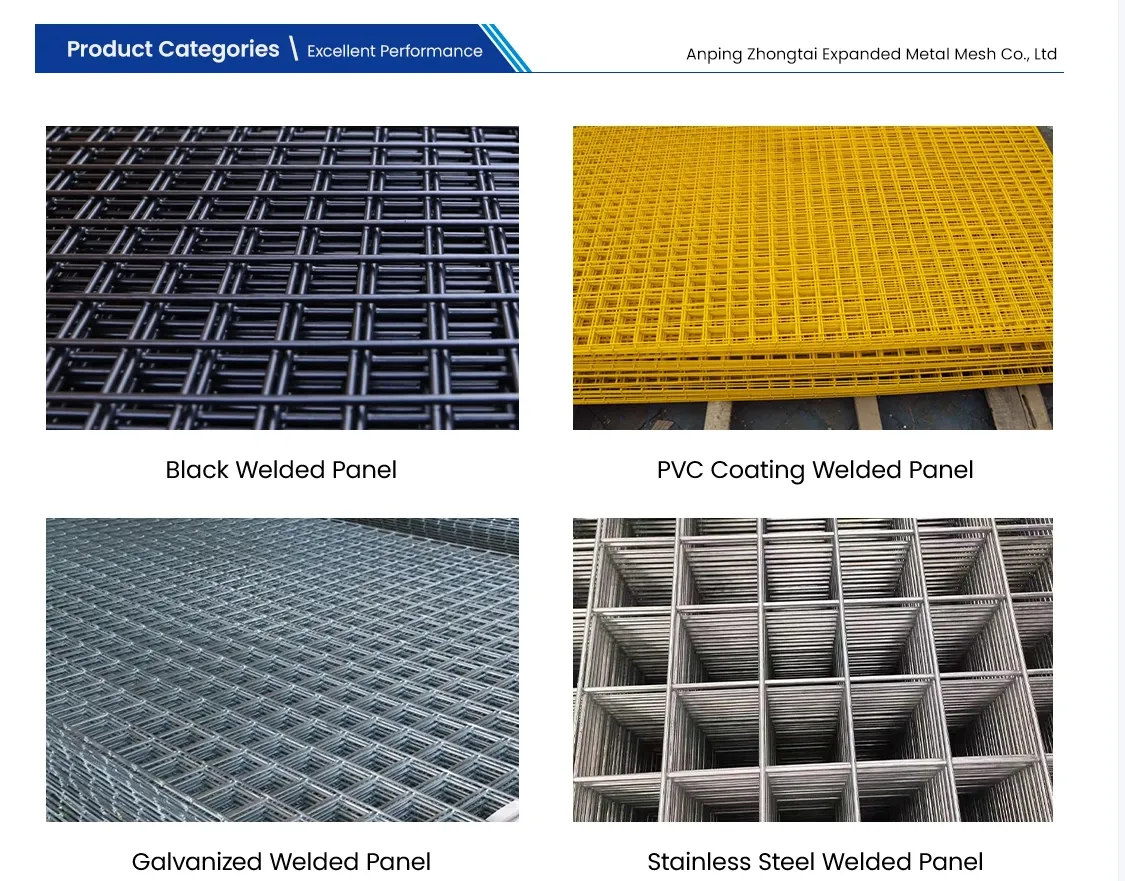

. The welding process provides a sturdy structure that resists bending and deformation, making it ideal for high-traffic areas where heavy loads are common. Additionally, the open-grid design allows for excellent drainage, preventing water accumulation and reducing slip hazards. This feature is particularly beneficial in outdoor environments where rain or spills can occur.Another significant benefit of welded steel grating is its aesthetic appeal. The clean lines and uniform structure of the grating can enhance the overall appearance of various installations, making it an attractive choice for architectural and landscaping projects. Furthermore, its versatility extends to surface treatments; it can be galvanized or painted to improve corrosion resistance, extending its lifespan and reducing maintenance costs.

welded steel grating

Welded steel grating is also environmentally friendly. It is 100% recyclable, contributing to a circular economy and making it a sustainable choice for construction and industrial applications. By selecting welded steel grating, companies can align their operations with modern environmental standards and showcase their commitment to sustainability.

Applications of Welded Steel Grating

The applications of welded steel grating are extensive and diverse. In industrial settings, it is commonly used for flooring in manufacturing plants, walkways, platforms, and safety barriers. Its strength and slip-resistant surface make it an ideal choice for locations where worker safety is a priority, including in mining, oil and gas, and chemical processing facilities.

In commercial contexts, welded steel grating is often utilized for stair treads, parking structures, and ventilation grilles. Its aesthetic appeal allows architects and designers to incorporate it into modern designs without compromising on functionality.

Conclusion

In summary, welded steel grating stands out as a durable, versatile, and aesthetically pleasing solution for various needs across multiple industries. Its robust construction, excellent drainage capabilities, and adaptability make it a reliable choice for both industrial and commercial applications. With the added advantage of sustainability, welded steel grating not only meets the demands of today’s projects but also contributes positively to the environment. Whether for heavy-duty industrial use or lighter commercial applications, welded steel grating remains a top choice for professionals seeking quality and reliability.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.