The Versatility of Perforated Plastic Mesh Panels

In the world of construction, landscaping, and various industrial applications, perforated plastic mesh panels have emerged as a versatile and effective solution. These panels, made from robust plastic materials, are not only lightweight but also offer a range of functional advantages. This article explores the characteristics, applications, and benefits of perforated plastic mesh panels.

Characteristics of Perforated Plastic Mesh Panels

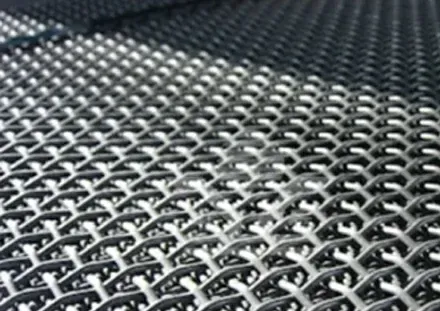

Perforated plastic mesh panels are engineered to provide a unique combination of durability and flexibility. They are composed of high-density polyethylene (HDPE) or polypropylene, materials well-known for their resistance to moisture, chemicals, and UV radiation. The perforations in the panels can vary in size and shape, which can be customized according to specific needs. This adaptability allows for optimal functionality in various environments.

One of the standout features of these panels is their breathability. The perforations enable air circulation, making them suitable for applications where ventilation is essential. Moreover, their lightweight nature simplifies transportation and installation, significantly reducing labor costs and time.

Applications of Perforated Plastic Mesh Panels

The versatility of perforated plastic mesh panels makes them suitable for a wide array of applications. In landscaping, they are often used as erosion control mats or as part of a drainage solution in gardens and green roofs. The panels allow for water to flow through while preventing soil loss, thus promoting a healthy plant environment.

In industrial settings, perforated plastic mesh panels are utilized for equipment protection, tool organization, and even as containment structures

. Their ability to withstand harsh conditions makes them ideal for factories and warehouses where traditional materials might fail.perforated plastic mesh panel

Moreover, these panels are frequently applied in agriculture. They can be used as fencing to protect crops from animals while allowing necessary sunlight and airflow. In aquaculture, perforated panels are used in tanks for filtering purposes, ensuring that water quality is maintained for aquatic life.

Benefits of Using Perforated Plastic Mesh Panels

The benefits of incorporating perforated plastic mesh panels into projects are numerous. First and foremost, their lightweight composition leads to easier handling and installation. This feature alone can significantly reduce labor costs, as fewer workers and less equipment are needed for setup.

Additionally, these panels are highly resistant to weather elements, ensuring long-lasting performance. Unlike metal or wooden alternatives, perforated plastic panels do not rust, rot, or corrode over time, which further contributes to their durability and reduces the need for frequent replacements.

Another considerable benefit is their eco-friendliness. Many perforated plastic mesh panels are made from recycled materials, making them an environment-friendly option for construction and landscaping projects. Their recyclability also means that when they are eventually no longer needed, they can be repurposed rather than ending up in a landfill.

Conclusion

In summary, perforated plastic mesh panels represent a remarkable solution for various applications across multiple industries. Their characteristics of durability, versatility, and lightweight design make them an ideal choice for landscaping, industrial uses, and agricultural settings. As sustainability becomes increasingly important in construction and design, these panels offer an environmentally friendly option without compromising on performance. As technology progresses, we can expect to see even more innovative uses for perforated plastic mesh panels, solidifying their place as a staple in modern construction and design practices.

Adopting perforated plastic mesh panels means investing in both quality and efficiency, offering a functional, cost-effective, and durable solution for today's diverse needs.

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.