Aluminum Sheet Metal with Holes Versatility and Applications

Aluminum sheet metal with holes is an essential material widely used in various industries due to its combination of lightweight, corrosion resistance, and high strength. The process of creating sheet metal involves transforming aluminum into flat plates, which can then be perforated to produce a variety of hole patterns. This article explores the significance, manufacturing techniques, and applications of aluminum sheet metal with holes.

Significance of Aluminum Sheet Metal

Aluminum is known for its impressive properties, including its excellent strength-to-weight ratio, thermal and electrical conductivity, and resistance to corrosion. When fashioned into sheet metal, these benefits can be further exploited. Sheet metal can be easily manipulated into different shapes and sizes, making it suitable for diverse applications. The addition of holes to the aluminum sheet enhances its functionality, allowing for ventilation, filtration, and lightweight structural support.

Manufacturing Techniques

The creation of aluminum sheet metal with holes often involves a process known as perforation. This can be done using several methods, including mechanical punching, laser cutting, and water jet cutting. Mechanical punching is the most common method for producing uniform holes, where a die is used to punch holes into the sheet. Laser cutting, on the other hand, offers more precision for complex designs and is ideal for intricate patterns. Water jet cutting utilizes a high-pressure jet of water mixed with abrasive materials, allowing for detailed cutting without altering the metal's properties due to heat.

Punching and perforating aluminum sheets not only allows for the creation of various hole sizes and patterns but also contributes to the aesthetic appeal of the finished product. Designs can range from simple round holes to complex patterns, catering to specific design requirements.

Applications

Aluminum sheet metal with holes finds application across numerous sectors

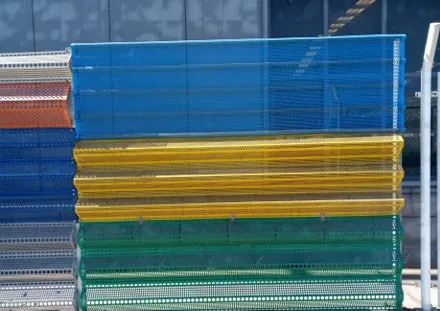

aluminum sheet metal with holes

1. Construction In building and construction, perforated aluminum is used in facades, ceilings, and decorative elements. Its lightweight nature while maintaining structural integrity makes it a preferred choice.

2. Automotive Perforated aluminum sheets are used in vehicle components for heat dissipation, reducing weight while ensuring durability. They are often found in parts like grilles and heat shields.

3. Aerospace In the aerospace industry, weight is a critical factor. Perforated aluminum sheets contribute to the overall reduction of weight without sacrificing strength, making them ideal for various aircraft components.

4. HVAC Systems Air conditioning systems and ventilation ducts often utilize perforated aluminum sheets. The holes allow for the efficient flow of air while preventing dust and debris ingress.

5. Furniture and Interior Design The aesthetic appeal of perforated aluminum has made it popular in modern furniture design, providing both functional and decorative elements.

6. Industrial Applications In factories, perforated aluminum sheets are used for screens, guards, and separators. They enable visibility and airflow while protecting sensitive machinery.

Conclusion

Aluminum sheet metal with holes is a versatile and valuable material in numerous industries. Its lightweight, corrosion-resistant properties, combined with the ability to be easily perforated, make it an ideal choice for both functional and aesthetic applications. As technology continues to advance in manufacturing techniques such as laser cutting and water jet cutting, the potential for innovative designs and applications for perforated aluminum sheets will only expand, making it a material of choice for engineers, designers, and manufacturers across the globe.

-

Versatility of Expanded Aluminum Metal for Various Applications

NewsMay.19,2025

-

The Geometry of Steel Gratings: Why It Matters

NewsMay.19,2025

-

Reinforcement Applications of Perforated Mesh in Masonry

NewsMay.19,2025

-

Essential Tools for Installing a Deck Mesh Railing

NewsMay.19,2025

-

Anti-Slip Flooring Made with Stainless Expanded Mesh

NewsMay.19,2025

-

Adjustable Steel Grating for Uneven Terrain

NewsMay.19,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.