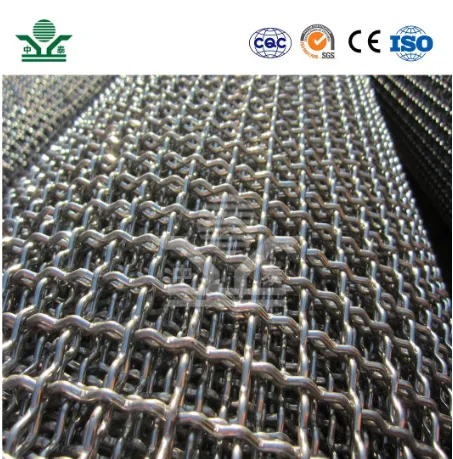

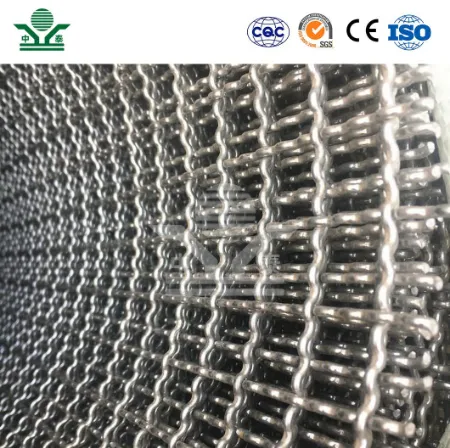

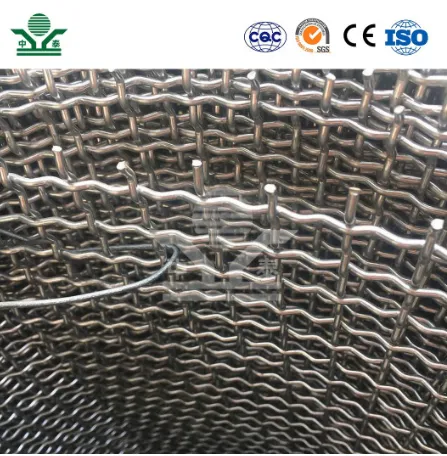

The demand for high-quality Weave Wire Mesh China Manufacturing 25 Gauge 23 Gauge 24 Gauge Double Crimp Wire Mesh has surged globally thanks to its robustness, precision functionality, and versatility in industrial settings. Within China, the manufacturing sector for wire mesh continually innovates to meet stringent application and safety standards, serving industries ranging from petrochemicals and metallurgy to architecture and water treatment. This comprehensive article explores technical features, manufacturing processes, comparative benchmarks, customization possibilities, and real-world application cases, all while aligning with the latest ISO, ANSI, and customer-driven performance standards.

Global Industry Trends: Wire Mesh Market Insights

According to Markets&Markets 2023, the global woven wire mesh market size is estimated to grow at a CAGR of 5.1% (2023–2028), with China contributing over 34% of world production. The ongoing adoption of automated manufacturing, stricter material traceability, and advanced surface treatments (galvanizing, PVC coating, etc.) are key industry drivers. Increasing demand for fine-gauge meshes (23, 24, 25 gauge) supports filtration, architectural, and security sectors, leveraging enhanced anti-corrosion and precise aperture features.

Technical Specifications for Weave Wire Mesh China Manufacturing 25 Gauge 23 Gauge 24 Gauge Double Crimp Wire Mesh

| Parameter | 23 Gauge | 24 Gauge | 25 Gauge | Double Crimp Type | Standard (ISO/ANSI) |

|---|---|---|---|---|---|

| Wire Diameter (mm) | 0.57 | 0.56 | 0.51 | 0.51~0.57 | ISO 9044 / ANSI/ASTM E2016 |

| Opening Size (mm) | 2.03 – 25.4 | 1.25 – 20.0 | 1.00 – 12.7 | Customizable | ISO 4783-3 |

| Mesh Count (per inch) | 10 – 120 | 10 – 120 | 12 – 150 | Up to 150 | ISO 9044 |

| Material | SS304/SS316, Galvanized Steel, Plain Carbon Steel | SS304/SS316, Galvanized Steel, Copper Alloy | SS304/SS316, PVC Coated, Aluminium | Low carbon steel, Stainless | ASTM A580 |

| Surface Finish | Galvanized, Polished, PVC coated | Zinc Coated, Black Annealed | Plain, Electro-galvanized | Double Crash Points | ISO 1461 |

| Tensile Strength (MPa) | 350–550 | 350–600 | 400–600 | >= 400 | ISO 6892-1 |

| Corrosion Resistance | High | Very High | Excellent | Superior | ISO 9227 |

| Temperature Resistance (°C) | Up to 800 | Up to 800 | Up to 650 | Up to 800 | ISO 7000 |

| Typical Applications | Filtration, Mining, Security | Chemical, Water Treatment | Architecture, Fencing | Decorative, Industrial | Industry Specific |

Manufacturing Process Flow: Weave Wire Mesh China Manufacturing 25 Gauge 23 Gauge 24 Gauge Double Crimp Wire Mesh

SS304/SS316 or carbon steel wire, verified by spectroscopic analysis per ASTM A580.

Drawn to precise gauge using CNC-controlled dies; annealed to achieve uniform ductility & tensile strength.

Each wire is pre-crimped at precise intervals on computer-regulated machines ensuring double-interlock strength.

Automatic looms weave crimped wires at defined mesh count and aperture, checked via ISO 9044 gauge.

Surface treated (galvanized, PVC coated) per ISO 1461; aperture, strength & corrosion tests per ISO 9227 & ASTM E2016.

Technical Advantages: Why Choose Weave Wire Mesh China Manufacturing 25 Gauge 23 Gauge 24 Gauge Double Crimp Wire Mesh?

- Uniform Aperture Stability: Double crimping ensures consistent mesh geometry, minimizing deformation under load.

- Superior Corrosion Resistance: Advanced galvanization, black annealing, or PVC coating technologies withstand harsh chemical & marine environments per ISO 9227 test protocols.

- Enhanced Load Capacity: Double interlock crimp structure increases point welding strength by up to 27% compared to plain woven meshes [1].

- Extensive Material Versatility: Compatible with multiple alloys, including SS304 (industrial standard for filters), SS316 (chloride environments), and high-carbon steels for abrasion resistance.

- Certification Ready: Manufactured to meet ISO 9044, ISO 4783-3, ASTM E2016, and custom regional standards.

- Dimensional Precision: Computer-controlled weaving guarantees aperture tolerance within ±2% (validated by laser gauge inspection).

- Extended Service Life: With proper treatment, tested average life >10 years in industrial environments.

Application Scenarios in Various Industries

- Petrochemical: Catalyst support grids, sand filtration, anti-splash screens due to high temperature and corrosion resistance.

- Metallurgy: Sintering trays, metal particle separation, process screens owing to robust load capacity.

- Water Treatment: Primary/secondary filtration meshes, debris screening panels because of long-term anti-fouling characteristics.

- Architecture: Facade cladding, infill panels, sunshades, and balustrades benefiting from aesthetic amp; structural versatility.

- Agriculture & Industrial: Grain drying trays, livestock fencing, mechanical sieves thanks to customizable aperture design and durability.

- Security: Window guards, fencing, machine guarding for strong anti-vandal performance.

Mesh Gauge Comparison & Performance Data Visualization

Manufacturer Comparison: China vs. Global Producers

| Factor | Top Chinese Factory (ZT Wire Mesh) | International Leader (W.S. Tyler, Germany) | Regional Standard |

|---|---|---|---|

| Annual Output (2023) | 5,500+ tons | 4,200 tons | N/A |

| Max Mesh Width (m) | 4.0 | 3.5 | ISO 4783-4 |

| Certification | ISO 9001, ISO 14001, SGS | ISO 9001, DIN 17100, TÜV | ISO/DIN/SGS |

| Automation Level | 95%, with full CNC weaving | 88%, semi-auto | N/A |

| Custom Production? | Full: Any gauge, size, material | Limited: Standard catalog | On demand |

| Delivery Cycle | 7–18 days | 21–35 days | N/A |

| Sample Service | Yes, free sample within 48H | Yes, 1–2 weeks | N/A |

Weave Wire Mesh China Manufacturing 25 Gauge 23 Gauge 24 Gauge Double Crimp Wire Mesh producers in China, particularly ZT Wire Mesh, have a competitive edge due to faster lead times, superior customizability, and decades-long export experience verified by ISO and SGS certifications.

Customization Options & Service Cases

Clients can specify material (stainless, carbon, copper alloy…), aperture size, mesh count, panel dimension, or surface treatment. Each order undergoes CAD drawing validation, pre-production sample approval, and full-scale mass production tracked by ERP traceability systems.

Verified by SGS test report #SGS-CQ2022/39A; customer reference available upon request.

Professional FAQ: Key Terminology Explained

-

Q: What material options are available for Weave Wire Mesh China Manufacturing 25 Gauge 23 Gauge 24 Gauge Double Crimp Wire Mesh?

A: The mesh can be produced from SS304/316 stainless steel (offering high corrosion and temperature resistance); galvanized low-carbon steel (for economic and structural applications), and special alloys (such as copper or Monel for non-magnetic and conductive uses). All wires are tested for chemical composition per ASTM A580 standards. -

Q: How is mesh gauge defined and which gauge is best for which application?

A: Gauge defines wire thickness (23 G ≈ 0.57mm, 24 G ≈ 0.56mm, 25 G ≈ 0.51mm). 23G and 24G are optimal for industrial filtration and screens, while 25G is suited for architectural and fine filtration tasks where minimal visual obstruction is needed. -

Q: What certification and testing standards are provided?

A: Products are supplied with ISO 9001 manufacturing quality certification, ISO 1461 galvanized finish, ASTM E2016 mesh dimension tests, and salt spray (corrosion) resistance tests per ISO 9227. Third-party testing by SGS or equivalent available. -

Q: What is double crimp, and why is it beneficial?

A: Double crimp involves two perpendicular sets of wires pre-crimped before weaving, securing each intersection and ensuring high mesh stability and resistance to deformation under tension or load—essential for heavy-duty and precise filtration uses. -

Q: How is mesh installed in industrial settings?

A: Mesh is typically supplied in rolls or pre-cut panels with edge finishing (welded, hooked, or framed). Installation follows industry codes such as ASTM F2006 for security, or project-specific specs. Mounting fixtures, tension bars, and clamps are supplied per customer request. -

Q: What is the lead time and delivery process?

A: Standard production cycle is 7–18 days depending on gauge and order size. All shipments undergo 100% inspection and are packed for sea/air freight with full traceability and export customs certifications attached. -

Q: What warranties and after-sales support are available?

A: All Weave Wire Mesh China Manufacturing 25 Gauge 23 Gauge 24 Gauge Double Crimp Wire Mesh comes with a 2–5 year product warranty (depending on environment and treatment), comprehensive installation guidance, and rapid-response technical support via online, phone, or on-site engineer services.

Delivery Cycle, Warranty & Customer Support

| Service Item | Details |

|---|---|

| Lead Time | 7–18 working days (custom sizes/materials up to 20 days) |

| Warranty | 2 years standard; up to 5 years for SS316/PVC coated under industrial conditions |

| Sample Policy | Free sample panels (A4) dispatched worldwide in 48 hours |

| Technical Support | 24/7 hotline, e-mail, on-site engineering, and video installation guidance |

| Certifications | ISO 9001, ISO 14001, SGS, and application-specific testing (ISO 9227, ASTM E2016) |

| After-Sales Response | Guaranteed reply in ≤6h, urgent dispatch for replacement parts |

Conclusion & References

The Weave Wire Mesh China Manufacturing 25 Gauge 23 Gauge 24 Gauge Double Crimp Wire Mesh stands as a proven, certified, and adaptable solution for demanding technical applications. Backed by industry-leading automation, material science, and client support infrastructure, Chinese manufacturers such as ZT Wire Mesh ensure reliability from initial inquiry to after-market service.

For further in-depth industry data and peer-validated application feedback, refer to:

- Mechanical Characteristics of Woven Wire Mesh (Advanced Engineering Materials, Wiley, 2018)

- WireNet Industrial Forum – Industry Statistics & Field Cases

- ASTM E2016-20: Standard Specification for Industrial Woven Wire Mesh

- Product Technical File: ZT Wire Mesh Official Product Page

- Durability Performance of Galvanized Woven Mesh (ResearchGate, 2022)

-

Why Galvanized Trench Cover Steel Grating Resists Corrosion

NewsJul.10,2025

-

The Versatility and Strength of Stainless Expanded Metal Mesh

NewsJul.10,2025

-

Load Calculations in Steel Grating Platforms

NewsJul.10,2025

-

Keeping Pets and Kids Safe with Chicken Wire Deck Railing

NewsJul.10,2025

-

Hole Diameter and Pitch for Round Perforated Metal Sheets

NewsJul.10,2025

-

Aluminium Diamond Mesh in Modern Architecture

NewsJul.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.