فبراير . 12, 2025 12:11

Back to list

Punching Hole Wire Mesh China Suppliers Perforated Sheet Metal

Perforated steel sheets, particularly those with a 3mm thickness, are highly valued across various industrial sectors for their unique set of properties and versatility. One of the most significant advantages of using perforated steel sheets is their ability to combine strength with flexibility, making them a favored choice for engineers and designers alike.

The authoritative standing of perforated steel sheets in industrial applications can be credited to their compliance with international standards and specifications. These sheets often meet and exceed industry benchmarks, ensuring reliability and trust among users. The adherence to standards such as ISO, ASTM, and BS enhances the credibility of manufacturers, and by extension, the platforms and projects that utilize these materials. This conformance not only ensures quality but also provides peace of mind to clients and project managers who can rely on the product’s consistent performance. Trustworthiness of the 3mm perforated steel sheet is further exemplified in its eco-friendly attributes. Steel, being 100% recyclable, allows for sustainable practices, making it an ideal choice for environmentally conscious projects. Manufacturers and suppliers often emphasize this aspect as part of their commitment to sustainability, enhancing the appeal of these materials in an era where ecological considerations are increasingly at the forefront of project planning. In addition to fundamental capabilities, the customization potential of perforated steel sheets plays a significant role in meeting specific project needs. Companies offer bespoke services, allowing customers to request unique perforation patterns, sizes, and finishes to suit particular aesthetic or functional requirements. This level of customization not only broadens the applications of these sheets but also enables companies to maintain a competitive edge in a crowded market. In conclusion, the 3mm thick perforated steel sheet stands out as a remarkably versatile and reliable product in the industrial landscape. Its balanced characteristics of strength, flexibility, and aesthetic potential make it an essential component in modern infrastructure, automotive design, and architectural projects. By aligning with international standards and supporting sustainable practices, it continues to hold a trustworthy position among manufacturers and users, ensuring its relevance and application for years to come.

The authoritative standing of perforated steel sheets in industrial applications can be credited to their compliance with international standards and specifications. These sheets often meet and exceed industry benchmarks, ensuring reliability and trust among users. The adherence to standards such as ISO, ASTM, and BS enhances the credibility of manufacturers, and by extension, the platforms and projects that utilize these materials. This conformance not only ensures quality but also provides peace of mind to clients and project managers who can rely on the product’s consistent performance. Trustworthiness of the 3mm perforated steel sheet is further exemplified in its eco-friendly attributes. Steel, being 100% recyclable, allows for sustainable practices, making it an ideal choice for environmentally conscious projects. Manufacturers and suppliers often emphasize this aspect as part of their commitment to sustainability, enhancing the appeal of these materials in an era where ecological considerations are increasingly at the forefront of project planning. In addition to fundamental capabilities, the customization potential of perforated steel sheets plays a significant role in meeting specific project needs. Companies offer bespoke services, allowing customers to request unique perforation patterns, sizes, and finishes to suit particular aesthetic or functional requirements. This level of customization not only broadens the applications of these sheets but also enables companies to maintain a competitive edge in a crowded market. In conclusion, the 3mm thick perforated steel sheet stands out as a remarkably versatile and reliable product in the industrial landscape. Its balanced characteristics of strength, flexibility, and aesthetic potential make it an essential component in modern infrastructure, automotive design, and architectural projects. By aligning with international standards and supporting sustainable practices, it continues to hold a trustworthy position among manufacturers and users, ensuring its relevance and application for years to come.

Latest news

-

The Strength and Versatility of Aluminum Expanded Metal Mesh

NewsJun.10,2025

-

Safety Guards and Machine Enclosures Using Expanded Mesh

NewsJun.10,2025

-

Performance with Round Hole Perforated Mesh in Wall Panels

NewsJun.10,2025

-

How Steel Grating Trench Covers Distribute Weight Efficiently

NewsJun.10,2025

-

How Deck Mesh Railing Enhances Backyard Aesthetics

NewsJun.10,2025

-

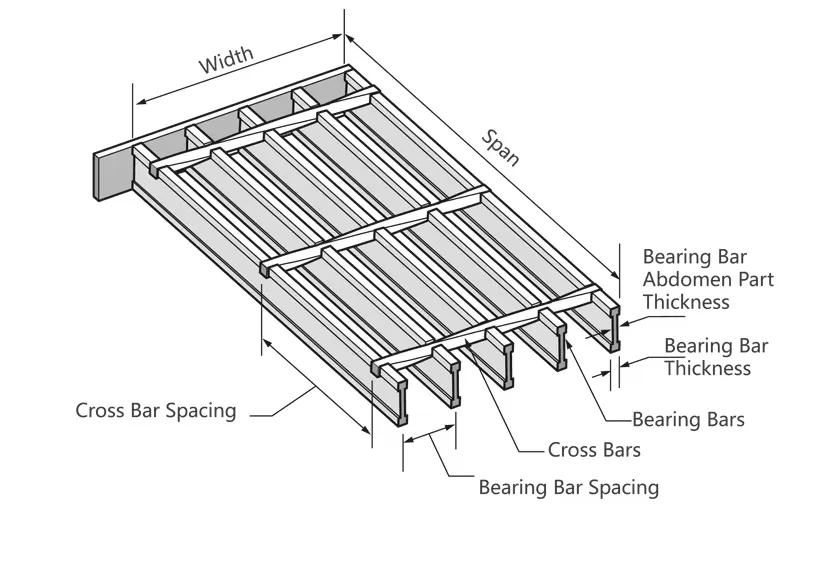

Comparing Bar Thickness and Spacing in Steel Grating

NewsJun.10,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP