Round Perforated Steel Sheet is a key solution in the manufacturing industry, specifically within Fabricated metal products and Manufacturing of metal wire mesh and products. This article explores how AnPing Zhongtai Expanded Metal Mesh Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Round Perforated Steel Sheet Overview

- Benefits & Use Cases of Round Perforated Steel Sheet in Manufacturing of metal wire mesh and products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Round Perforated Steel Sheet from AnPing Zhongtai Expanded Metal Mesh Co., Ltd

Round Perforated Steel Sheet Overview

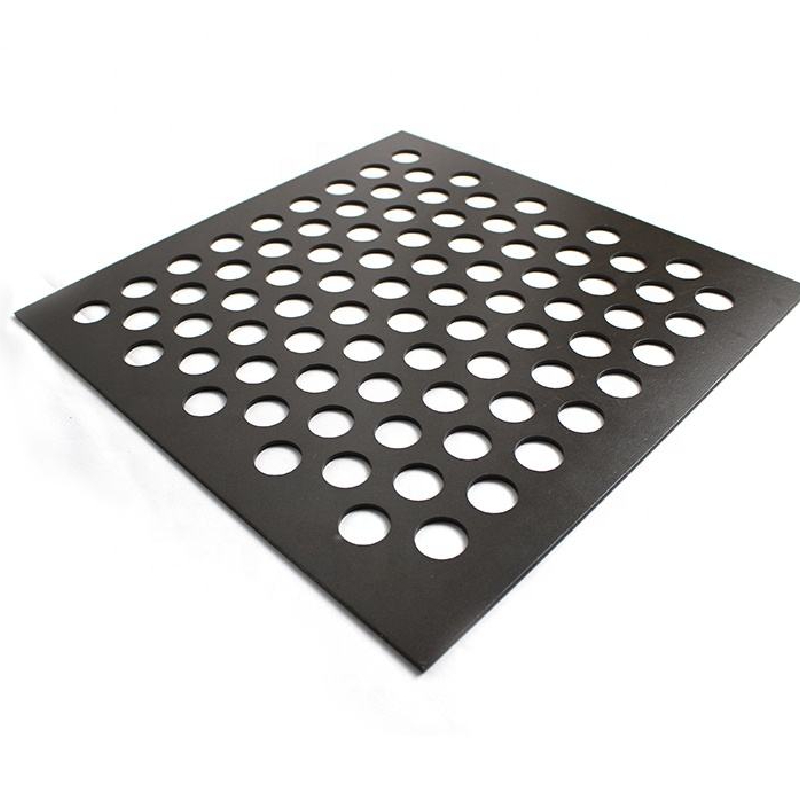

A round perforated steel sheet—also known as a round perforated sheet or round perforated metal sheet—is a flat metal panel punched with uniform round holes in straight or staggered patterns. In the fabricated metal products sector, it’s prized for controlled open area, predictable airflow, and excellent strength-to-weight ratios. Typical specifications include hole diameters from 0.5–20 mm, thickness 0.3–10 mm, pitch tailored to target open area (often 10–60%), and standard sheets such as 1000 × 2000 mm and 1220 × 2440 mm, as well as custom sizes. Materials range from cold-rolled and galvanized steel to stainless grades (e.g., 304/316) for higher corrosion resistance, often with finishes like powder coating or hot-dip galvanizing.

- Relevance: Ensures calibrated filtration, ventilation, screening, and protection in material handling, HVAC, enclosures, and process equipment.

- Technical background: 60° staggered round-hole patterns deliver superior load distribution; CNC punching supports tight tolerances and repeatability; deburring and leveling improve downstream fabrication.

- Reliable source: AnPing Zhongtai Expanded Metal Mesh Co., Ltd provides round hole perforated sheet in diverse alloys and patterns, with fast tooling, accurate nesting, and consistent quality. Explore specs here: Round hole perforated metal sheet.

Benefits & Use Cases of Round Perforated Steel Sheet in Manufacturing of metal wire mesh and products

In metal wire mesh and related products, round perforated metal is a go-to for screens, guards, acoustic panels, ventilation grilles, separation plates, and reinforcement liners. Compared with woven wire, a round hole perforated metal sheet offers fixed aperture geometry, uniform pressure drop, and enhanced formability for rolling, bending, or deep drawing. For corrosive or hygienic environments—such as food, pharma, and chemical processing—round hole perforated stainless steel sheet (304/316) ensures cleanability and longevity. In OEMs and fabricators, it is commonly integrated into machine guarding, hopper and chute liners, dust extraction ducts, architectural façades, and speaker grilles.

- Competitive advantages: predictable open area for airflow and acoustics, high rigidity versus weight, and excellent edge quality for automated assembly.

- Application highlights: filtration and screening in aggregates and recycling; air intake/exhaust covers in HVAC; perforated trays, racks, and baskets in fabrication shops.

- Supplier expertise: AnPing Zhongtai Expanded Metal Mesh Co., Ltd customizes hole size, pitch, margins, and sheet size to your drawing—supporting rapid prototyping through to scaled production of round hole perforated metal.

Cost, Maintenance & User Experience

Total cost of ownership for a round perforated steel sheet hinges on material selection, open-area targets, and finishing. Carbon steel offers the lowest upfront cost; galvanized or powder-coated options extend life in general outdoor conditions; stainless steel maximizes durability where corrosion is critical. Because round perforated metal sheet maintains its geometry under load, users see fewer deformation-related defects during forming and welding, reducing scrap and rework. Cleaning is straightforward—compressed air or washdown—thanks to smooth, deburred surfaces and consistent perforations.

- Durability & ROI: Long service life and high dimensional stability translate into lower maintenance intervals, consistent airflow/filtration performance, and predictable throughput.

- User feedback: Fabricated metal products customers typically report faster fit-up in assemblies, fewer edge-quality issues after cutting, and reliable repeatability from lot to lot—key to lean production and on-time deliveries.

Sustainability & Market Trends in manufacturing

Sustainability priorities are reshaping perforated metal choices: lightweighting to reduce energy consumption, recyclable materials to support circularity, and designs that improve airflow and acoustic control for healthier, safer workplaces. Steel and stainless steel are highly recyclable, and perforation patterns can minimize mass while retaining strength—reducing material use without compromising performance. Additionally, tightening safety and noise regulations, plus the growth of energy-efficient HVAC and advanced filtration, are expanding demand for round hole perforated sheet solutions across industrial, commercial, and architectural markets.

- Eco-conscious practices: AnPing Zhongtai Expanded Metal Mesh Co., Ltd emphasizes efficient nesting to cut scrap, supports recyclable packaging, and offers coatings aligned with modern environmental standards where specified.

- Forward-looking supply: With flexible tooling and material options—including round perforated metal in galvanized and stainless variants—buyers can balance sustainability goals with performance and cost targets.

Conclusion on Round Perforated Steel Sheet from AnPing Zhongtai Expanded Metal Mesh Co., Ltd

Round perforated steel sheet—whether specified as round perforated metal, round hole perforated metal sheet, or round hole perforated stainless steel sheet—delivers reliable airflow, filtration, and structural performance for the fabricated metal products sector. By combining precision punching, broad material options, and responsive service, AnPing Zhongtai Expanded Metal Mesh Co., Ltd streamlines your path from design to production with consistent, high-quality output.

- Count on proven value, durability, and ease of fabrication in Manufacturing of metal wire mesh and products.

- Partner with a trusted manufacturer committed to performance and support.

- Contact us: email: hht15531800319@outlook.com — Visit our website: https://www.ztwiremesh.com

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.