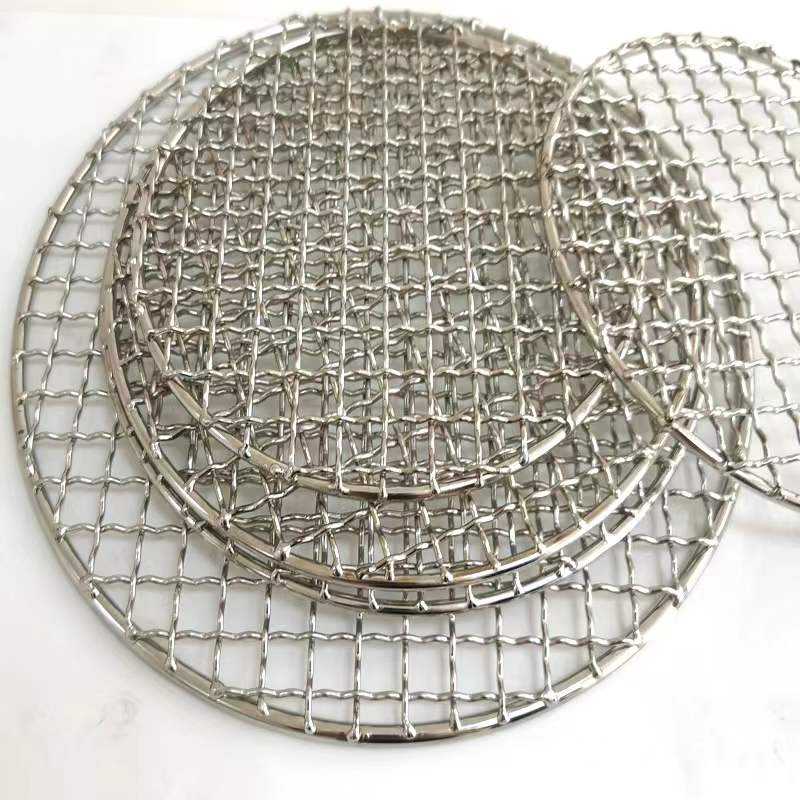

Introduction to BBQ Crimped Wire Mesh in Industrial Applications

In diverse industrial sectors, the demand for robust and reliable filtration and support structures is paramount. Among these, BBQ Crimped Wire Mesh stands out as a critical component, revered for its exceptional structural integrity, precise aperture control, and adaptability across a spectrum of challenging environments. Beyond its common association with culinary applications, this specialized mesh serves vital functions in heavy industry, chemical processing, and various engineering disciplines where precise particle separation, structural reinforcement, and high-temperature resistance are non-negotiable requirements.

This article delves into the technical intricacies, manufacturing excellence, and strategic advantages of crimped wire mesh, providing B2B decision-makers and engineers with comprehensive insights into its capabilities. We will explore its detailed process flow, adherence to stringent industry standards, and its transformative role in optimizing operational efficiency and longevity within industrial frameworks.

Industry Trends and Market Dynamics

The market for industrial wire mesh products, including specialized solutions like BBQ Crimped Wire Mesh, is experiencing sustained growth driven by global industrialization, infrastructure development, and increasing automation. Key trends include a heightened demand for materials with enhanced corrosion resistance and high-temperature performance, such as stainless steel grades (e.g., SS304, SS316), as industries strive for longer operational lifespans and reduced maintenance overheads. The rise of automation in manufacturing processes also necessitates components with tight dimensional tolerances and consistent material properties.

Furthermore, environmental regulations and safety standards are becoming more stringent, pushing manufacturers to innovate with non-toxic, sustainable materials and production methods. The shift towards customized solutions, tailored to specific application parameters rather than off-the-shelf products, also marks a significant trend, allowing for optimized performance in highly specialized environments like petrochemical filtration or precision screening in food processing. According to recent market analysis reports, the global industrial wire mesh market is projected to grow at a CAGR of approximately 4-6% over the next five years, indicating a robust and expanding sector.

Technical Specifications and Parameters

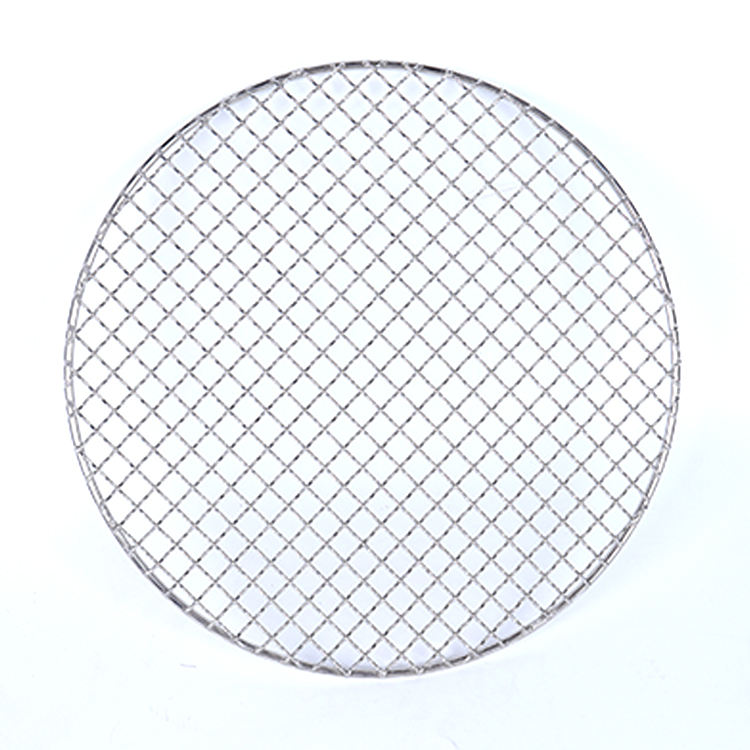

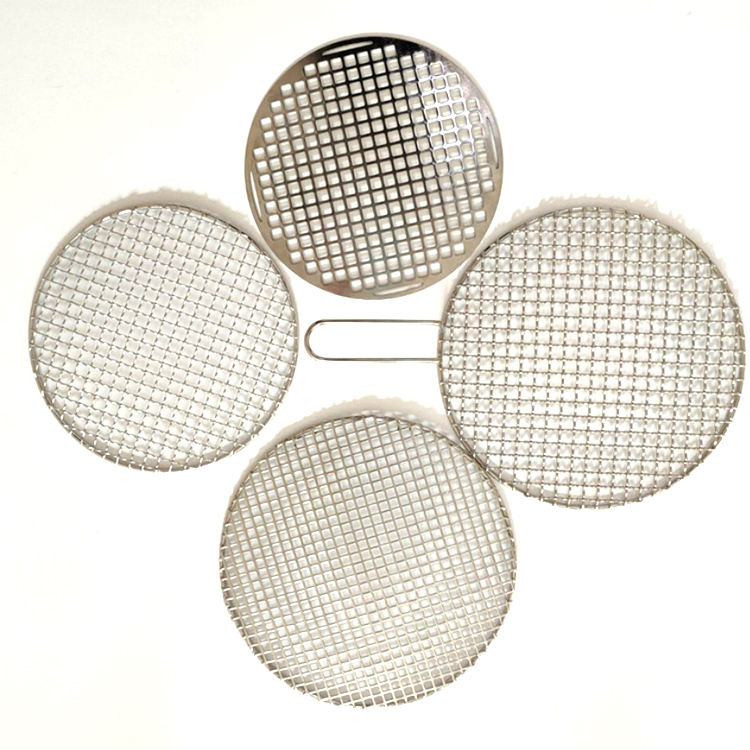

The efficacy of BBQ Crimped Wire Mesh in industrial applications is directly linked to its precise technical specifications. The crimping process, which imparts corrugations into the individual wires prior to weaving, is crucial. This pre-crimping technique ensures that warp and shute wires interlock securely, preventing mesh distortion and maintaining consistent aperture sizes under stress. Key parameters include:

- Material Composition: Typically manufactured from high-grade Stainless Steel (SS304, SS316, SS316L) for superior corrosion and heat resistance, galvanized steel for cost-effectiveness and moderate protection, or carbon steel for high strength and wear resistance in less corrosive environments.

- Wire Diameter: Ranging from 0.8 mm to 6.0 mm, dictating the mesh's robustness and load-bearing capacity.

- Mesh Opening (Aperture Size): Precisely controlled from 1 mm to 100 mm, crucial for filtration accuracy or material support.

- Crimping Patterns: Including plain crimp (single intermediate crimp), double crimp (crimps in both warp and shute), lock crimp (defined crimps at wire intersections for extreme rigidity), and flat top crimp (smooth surface for material flow).

- Panel Dimensions: Available in standard rolls or cut-to-size sheets, with typical widths up to 2 meters and lengths up to 30 meters, customizable to project requirements.

- Temperature Resistance: Stainless steel variants can withstand temperatures up to 800°C (1472°F) or higher depending on the grade, making them suitable for high-temperature furnaces or catalytic converters.

Product Specification Table: BBQ Crimped Wire Mesh (SS304)

| Parameter | Specification (Typical) | Notes |

|---|---|---|

| Material | Stainless Steel 304 (UNS S30400) | Excellent corrosion resistance, good formability |

| Wire Diameter Range | 1.5 mm - 4.0 mm | Standard industrial range |

| Mesh Opening Range | 5 mm - 50 mm | Filter media, protective barriers |

| Crimping Type | Double Crimp / Lock Crimp | For enhanced stability and rigidity |

| Temperature Resistance | Up to 800°C (1472°F) | Suitable for high-heat environments |

| Standards Compliance | ASTM E2016, ISO 9001 (QMS) | Ensures material and manufacturing quality |

These specifications are crucial for engineers to select the appropriate mesh for demanding applications, ensuring optimal performance and safety.

Manufacturing Process Flow

The production of high-quality BBQ Crimped Wire Mesh involves a meticulously controlled multi-stage process, ensuring precision, durability, and adherence to industry standards.

-

1. Material Selection and Preparation:

Raw materials, primarily high-grade stainless steel coils (e.g., SS304, SS316, SS316L), galvanized steel, or carbon steel, are meticulously selected based on the end-application's environmental and mechanical requirements. These materials are certified to meet international standards such as ASTM A240 for stainless steel, ensuring consistent chemical composition and mechanical properties.

-

2. Wire Straightening and Cutting:

The raw wire coils are fed into precision straightening machines to eliminate any curvature or imperfections. Subsequently, the wires are cut to specific lengths required for the weaving process, maintaining tight dimensional tolerances.

-

3. Crimping Process:

This is a defining step. Individual wires undergo a precise crimping process using specialized machinery. Depending on the desired mesh stability and rigidity, various crimp patterns are applied:

- Pre-crimping: Wires are crimped before weaving, ensuring uniform mesh openings and robust intersections.

- Double Crimp: Provides extra rigidity, suitable for heavy-duty applications.

- Lock Crimp: Offers maximum stability, where each wire is crimped at the point of intersection.

-

4. Weaving:

Crimped wires are then fed into heavy-duty weaving looms. The pre-crimping ensures that the warp (longitudinal) and shute (transverse) wires interlock perfectly, forming a stable and precise mesh pattern. This process is crucial for maintaining consistent aperture size and mesh integrity.

-

5. Shearing and Edging:

The woven mesh panels are then cut to the required dimensions using precision shearing equipment. Edging or selvedge treatment, such as welded edges or folded edges, can be applied to prevent fraying and provide additional structural stability, enhancing safety and ease of handling.

-

6. Cleaning and Surface Treatment:

For stainless steel meshes, passivation or electropolishing may be performed to remove surface contaminants, enhance corrosion resistance, and achieve a desired aesthetic finish, particularly for food-grade or medical applications. Galvanized meshes undergo hot-dip galvanization for robust zinc coating.

-

7. Quality Inspection and Testing:

Every batch undergoes rigorous quality control. This includes visual inspection for defects, dimensional checks (mesh opening, wire diameter, panel size), and mechanical tests (tensile strength, flatness). Products adhere to international testing standards such as ISO 9001 for quality management systems and ASTM E2016 for industrial woven wire mesh, ensuring reliability and performance consistency.

-

8. Packaging and Shipment:

Finished mesh products are carefully packaged to prevent damage during transit, often in wooden crates or rolls wrapped in protective materials, ready for global distribution.

Application Scenarios and Target Industries

The robust and versatile nature of BBQ Crimped Wire Mesh makes it indispensable across a multitude of industrial sectors. Its ability to maintain structural integrity and precise aperture in demanding conditions is highly valued.

- Petrochemical Industry: Used in catalytic cracking units, gas-liquid separators, and support grids for various filtering media. The corrosion resistance of stainless steel variants is critical in aggressive chemical environments.

- Metallurgy & Mining: Employed in vibratory screens for grading minerals, aggregates, and coal. The high tensile strength and abrasion resistance ensure extended service life in harsh mining conditions.

- Food Processing & Pharmaceutical: For applications requiring hygienic surfaces, stainless steel crimped mesh is used in drying trays, sorting screens, and filtration systems, adhering to FDA compliance for food contact materials.

- Water Supply & Drainage: Functions as filtration screens in water treatment plants, intake screens for pumps, and particulate removal in wastewater management, offering significant corrosion resistance.

- Architecture & Construction: Utilized for decorative facades, balustrades, security screens, and infill panels, providing both aesthetic appeal and structural safety.

- Automotive & Mechanical Engineering: Found in engine air filters, soundproofing panels, and protective guards for machinery.

- Heat Treatment & Furnaces: High-temperature resistant alloys are used as support trays or baskets in industrial furnaces and heat treatment processes.

Technical Advantages and Performance Benefits

The inherent design and material properties of BBQ Crimped Wire Mesh confer several distinct advantages in demanding industrial environments:

- Superior Structural Stability: The pre-crimping of wires before weaving ensures a "locked" mesh structure. This prevents wire movement, maintains consistent aperture size, and significantly enhances the mesh's rigidity and load-bearing capacity, crucial for screening heavy materials or acting as robust support.

- Precise Filtration and Separation: Due to its stable apertures, crimped mesh offers highly accurate particle separation, minimizing bypass and ensuring consistent product quality in filtration or sizing applications.

- Extended Service Life: Materials like SS304 and SS316 provide exceptional corrosion resistance against acids, alkalis, and oxidative environments, drastically extending the mesh's operational life compared to conventional materials. Its robust construction also offers superior abrasion resistance.

- High-Temperature Resistance: Stainless steel variants are ideal for applications involving extreme heat, maintaining their mechanical properties and structural integrity in high-temperature furnaces, dryers, and heat exchangers, contributing to energy saving by enabling efficient heat transfer.

- Enhanced Safety and Hygiene: For food and pharmaceutical applications, the smooth, non-porous surface of electropolished stainless steel crimped mesh inhibits bacterial growth and simplifies cleaning, supporting HACCP compliance and operational hygiene.

- Versatility in Application: Available in a wide range of wire diameters, mesh openings, and materials, it can be tailored to various specific needs, from fine screening to heavy-duty support structures.

Vendor Comparison and Customization

Selecting the right vendor for industrial BBQ Crimped Wire Mesh is critical for ensuring product quality, reliability, and cost-effectiveness. Key factors in vendor comparison include manufacturing capabilities, quality certifications, customization options, and after-sales support.

Vendor Comparison Matrix

| Feature | Leading Supplier A (e.g., ZT Wire Mesh) | Supplier B (Generic) | Supplier C (Budget) |

|---|---|---|---|

| Quality Certifications | ISO 9001:2015, ASTM, FDA (for specific grades) | ISO 9001 (basic) | Internal QA |

| Customization Capabilities | Full range: material, wire dia, mesh, crimp, panel size, edging, surface treatment | Limited options for standard sizes | Minimal, only standard products |

| Material Traceability | 100% material certs, full traceability | Partial traceability | Limited or none |

| Technical Support | Dedicated engineering team, design consultation | Basic product information | Self-service |

| Lead Time Reliability | High, established supply chain, proactive communication | Moderate, potential delays | Unpredictable |

Customized Solutions

Recognizing that industrial applications often demand unique solutions, leading manufacturers offer extensive customization. This includes:

- Material Specification: Beyond standard SS304/316, custom orders for alloys like Duplex Stainless Steel, Nickel Alloys, or specialty high-carbon steel are often accommodated for extreme conditions.

- Dimensional Precision: Exact wire diameters, mesh openings, and panel sizes (length, width) are produced to integrate seamlessly into existing systems.

- Edge Finishing: Specialized edge treatments such as bent edges, welded frames, or reinforced borders for specific installation requirements.

- Surface Treatments: Options like PTFE coating for non-stick properties, powder coating for aesthetics and added corrosion resistance, or specialized passivation for ultra-clean environments.

- Fabrication: Ability to fabricate mesh into specific shapes, baskets, cylinders, or integrated components with other materials.

Application Case Studies

Real-world applications demonstrate the tangible benefits of properly engineered BBQ Crimped Wire Mesh.

Case Study 1: Enhanced Filtration in Chemical Processing

A major petrochemical client was experiencing frequent failures of their filtration screens in a highly corrosive acid catalyst recovery system. The existing welded mesh panels were prone to fatigue and aperture distortion under the extreme temperature (250°C) and corrosive chemical exposure. Upon consultation, we provided custom-fabricated SS316L crimped wire mesh panels with a 5mm square opening and 3mm wire diameter, featuring a double crimp pattern for enhanced rigidity. The intrinsic stability of the crimped weave, combined with the superior corrosion resistance of SS316L, resulted in a 300% increase in screen service life, significantly reducing downtime and maintenance costs, saving the client an estimated $150,000 annually.

Case Study 2: Optimized Screening in Aggregate Mining

An aggregates producer faced challenges with premature wear and inconsistent sizing on their vibratory screens, leading to increased material recirculation and reduced throughput. Analysis revealed that standard plain weave mesh lacked the necessary rigidity to withstand the constant abrasive impact of crushed stone. We implemented heavy-duty carbon steel crimped wire mesh, specified with a lock crimp design and 5.0 mm wire diameter for a 40 mm aperture. The lock crimp construction ensured that the wires remained firmly in place, resisting wear and maintaining precise sizing. This led to a 25% improvement in screening efficiency and a doubling of screen lifespan, directly contributing to increased plant productivity.

Frequently Asked Questions (FAQ)

-

Q: What is the primary advantage of crimped wire mesh over plain weave mesh?

A: The pre-crimping process in BBQ Crimped Wire Mesh locks the wires in place, providing superior structural rigidity, preventing wire movement, and maintaining consistent aperture sizes under vibration and stress, unlike plain weave which can distort.

-

Q: Which material is best for high-temperature applications?

A: For high-temperature environments (up to 800°C+), Stainless Steel grades like SS304, SS316, or specialized high-nickel alloys are recommended due to their excellent heat and oxidation resistance.

-

Q: How do I determine the correct mesh opening and wire diameter for my application?

A: This depends on the particle size to be separated, the required flow rate, and the load/abrasion it will endure. Our technical team can assist you in selecting the optimal specifications based on your operational parameters and process requirements.

-

Q: Are your products certified for food contact?

A: Yes, our stainless steel BBQ Crimped Wire Mesh products (specifically SS304 and SS316) can be manufactured to meet FDA compliance standards for food contact applications, often with additional surface treatments like electropolishing.

Lead Time, Warranty, and Customer Support

Understanding the logistical and support aspects of industrial component procurement is crucial for B2B operations. We are committed to transparency and reliability.

Lead Time and Fulfillment

Standard BBQ Crimped Wire Mesh products typically have a lead time of 2-4 weeks, depending on order volume and specific customizations. For urgent requirements, expedited production and shipping options are available upon request. We maintain robust inventory levels of raw materials and operate efficient production lines to minimize delays and ensure timely delivery. Detailed lead time estimates are provided at the quotation stage.

Warranty Commitments

All our crimped wire mesh products come with a standard 12-month warranty against manufacturing defects and material failures under normal operating conditions. This warranty reflects our confidence in the quality and durability of our products, manufactured under strict ISO 9001 quality management systems. Extended warranty options can be discussed for specific high-value or long-term projects.

Customer Support and After-Sales Service

Our dedicated customer support team provides comprehensive technical assistance from product selection to post-installation queries. We offer:

- Technical Consultation: Expert advice on material selection, mesh configuration, and application-specific solutions.

- Order Tracking: Real-time updates on your order status and shipping.

- Troubleshooting: Assistance with any operational challenges or performance issues.

- Replacement Parts: Efficient processing of warranty claims and replacement part orders.

Our goal is to build long-term partnerships through reliable products and responsive service.

Conclusion

The industrial application of crimped wire mesh represents a sophisticated solution to diverse engineering challenges, offering unparalleled durability, precision, and adaptability. Its critical role across sectors from petrochemical to food processing underscores its value as a fundamental component for operational efficiency and safety. By combining advanced manufacturing processes, adherence to stringent quality standards, and a focus on customized solutions, leading suppliers are continuously elevating the performance benchmarks for this essential material. Investing in high-quality crimped wire mesh is an investment in long-term reliability and superior industrial performance.

References

- ASTM International. (2018). ASTM E2016-11(2018) Standard Specification for Industrial Woven Wire Cloth. West Conshohocken, PA: ASTM International.

- ISO 9001:2015 Quality management systems – Requirements. International Organization for Standardization.

- Davis, J.R. (Ed.). (1994). Stainless Steels. ASM Specialty Handbook. ASM International.

- Materials Performance & Characterization Journal. (Various Issues). ASTM International.

- Manufacturing Engineering & Technology. (Various Editions). McGraw-Hill Education.

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.