Introduction to Advanced Perimeter Solutions

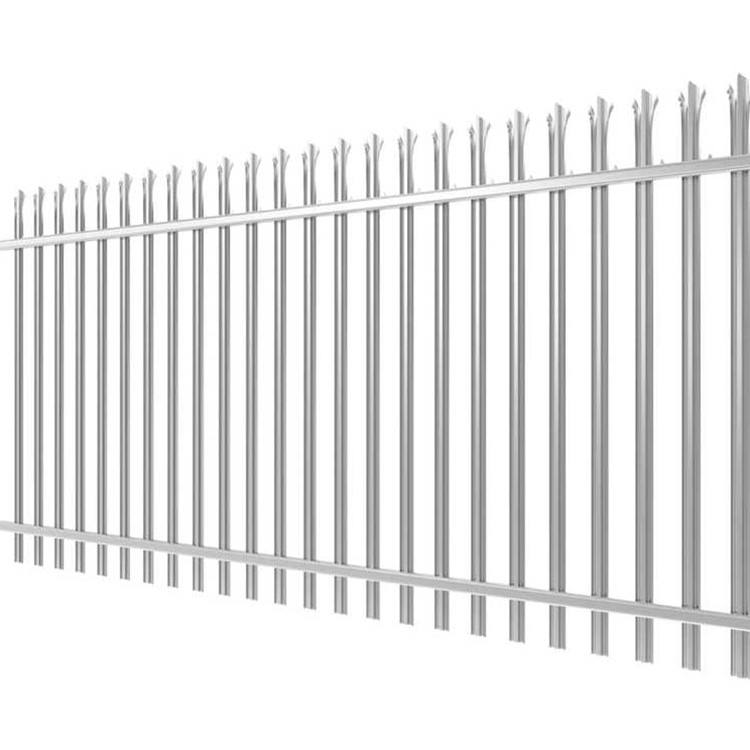

In contemporary industrial and commercial landscapes, the demand for robust, aesthetically pleasing, and highly durable perimeter security solutions is paramount. Among the diverse offerings, the European fence stands out as a preeminent choice, engineered to provide optimal protection while seamlessly integrating with various architectural and environmental contexts. This advanced fencing system, renowned for its rigidity, longevity, and versatile design, addresses critical security and aesthetic requirements across a multitude of sectors, from petrochemical facilities to public infrastructure projects. Its sophisticated construction and superior surface treatments ensure an extended operational lifespan and minimal maintenance, establishing it as a cost-effective and reliable investment for discerning B2B decision-makers.

Industry Trends and Market Dynamics in Perimeter Security

The global perimeter security market is currently experiencing significant growth, driven by escalating security threats, stringent regulatory compliance, and increasing urbanization. Key trends include the integration of smart technologies, such as IoT sensors and AI-powered surveillance, with physical barriers. There is a growing preference for solutions that offer enhanced durability and corrosion resistance, particularly in challenging environmental conditions, which directly benefits high-quality systems like the European fence. Furthermore, sustainability and aesthetic integration are becoming crucial factors, pushing manufacturers to innovate with eco-friendly materials and visually appealing designs. The demand for modular, easy-to-install systems that minimize disruption during deployment is also on the rise, underscoring the shift towards efficiency and long-term value in infrastructure projects.

Emerging markets in Asia-Pacific and Latin America are showing robust demand for high-grade fencing solutions as industrialization and infrastructure development accelerate. In mature markets like Europe and North America, the focus is increasingly on upgrading existing security infrastructure with advanced, maintenance-free options. The average annual growth rate for the perimeter security market is projected to be around 8-10% from 2023 to 2028, indicating a healthy environment for premium products.

Detailed Manufacturing Process Flow of European fence

The production of a European fence involves a meticulously controlled, multi-stage process designed to ensure unparalleled strength, durability, and corrosion resistance. Adherence to international standards such as ISO 9001 for quality management and relevant EN standards for steel wire products (e.g., EN 10223-4) is rigorously maintained at each step.

1. Material Selection

High-grade low-carbon steel wire (e.g., Q195 or Q235, as per ASTM A641) is selected for its optimal balance of strength and ductility. Strict material traceability protocols are in place to ensure compliance with specified metallurgical compositions, guaranteeing the foundational quality for long service life, typically 15-25 years under normal conditions.

2. Wire Drawing & Straightening

The steel rods undergo a precise wire drawing process to achieve the desired wire diameters (e.g., 4.0mm, 5.0mm, 6.0mm). Subsequent straightening ensures perfect linearity, crucial for consistent mesh formation and panel integrity. This process prepares the wire for uniform welding, impacting overall panel flatness and strength.

3. Automated Welding

Using advanced automated welding machines, the horizontal and vertical wires are resistance-welded at their intersections to form rigid mesh panels with precise mesh openings (e.g., 50x200mm, 50x100mm). This ensures maximum joint strength, preventing panel deformation and enhancing anti-climb characteristics.

4. Bending (3D Panels)

For 3D European fence panels, strategic V-bends are integrated using specialized bending machinery. These bends significantly enhance the panel's rigidity and anti-climb properties, contributing to structural stability and aesthetic appeal, particularly important in urban and commercial applications.

5. Surface Treatment (Galvanization)

Panels undergo hot-dip galvanization (EN ISO 1461) or electro-galvanization. Hot-dip galvanization creates a robust zinc coating (typically 40-80 g/m² for electro, 200-600 g/m² for hot-dip) that provides cathodic protection, significantly extending service life and offering superior corrosion resistance, crucial for industries like petrochemical and water treatment.

6. Powder Coating

Following galvanization, panels are often polyester powder-coated (typically 80-120 microns thickness) in various RAL colors. This adds a secondary layer of protection against UV degradation and corrosion, while providing an attractive finish. The dual-layer protection system offers exceptional longevity and reduced maintenance costs.

7. Quality Control & Packaging

Each panel undergoes rigorous quality checks, including weld strength tests, coating thickness measurements, and dimensional verification, complying with ISO and ANSI standards. Approved panels are then carefully bundled and packaged to prevent damage during transit, ensuring product integrity upon delivery to target industries such as metallurgy and general infrastructure.

Technical Specifications and Parameters

Understanding the precise technical parameters of a European fence is crucial for ensuring its suitability for specific project requirements. The robust design is characterized by specific wire gauges, mesh apertures, panel dimensions, and post specifications, all engineered for maximum security and durability.

Technical Advantages of European fence

- ✓ Superior Durability & Longevity: The combination of high-grade steel and advanced dual-layer surface treatment (hot-dip galvanization and polyester powder coating) provides exceptional resistance to rust, UV radiation, and harsh weather conditions. This significantly extends the service life beyond traditional fencing, often exceeding 15-20 years, minimizing replacement and maintenance costs.

- ✓ Enhanced Security Features: The rigid welded mesh panels, often with integrated V-bends, provide a formidable barrier. Small mesh apertures make climbing difficult, while the robust construction resists cutting and tampering. This makes it an ideal solution for critical infrastructure requiring high-level perimeter protection.

- ✓ Low Maintenance Requirements: Thanks to its robust construction and corrosion-resistant coatings, the European fence requires minimal ongoing maintenance. This translates to reduced operational expenditures for businesses and public entities, offering significant long-term savings.

- ✓ Aesthetic Appeal: Available in a wide range of RAL colors, this fencing system offers a professional and modern appearance that can be tailored to complement the architectural design of any facility. Its sleek design maintains an open view while providing formidable security.

- ✓ Ease and Speed of Installation: The modular design, featuring pre-fabricated panels and posts, facilitates quick and straightforward installation. This reduces labor costs and project timelines, making it a highly efficient choice for large-scale deployments.

Application Scenarios Across Diverse Industries

The versatility and robust performance of the European fence make it suitable for a broad spectrum of applications, providing reliable perimeter security and delineation across various industries. Its design allows it to adapt to different environmental and operational demands.

- Industrial & Manufacturing Facilities: Securing factories, warehouses, logistics centers, and power plants against unauthorized access, safeguarding valuable assets and ensuring operational continuity.

- Petrochemical & Energy Sector: Providing corrosion-resistant barriers for refineries, pipelines, and renewable energy sites where environmental resilience and stringent safety protocols are paramount. Its protective coatings are critical for longevity in chemically active zones.

- Public Infrastructure & Utilities: Protecting airports, railway lines, bridges, water treatment plants, and telecommunication facilities. For water supply and drainage systems, the fence's resistance to moisture and pollutants is a distinct advantage, ensuring long-term structural integrity.

- Commercial & Residential Developments: Enhancing security and aesthetics for office parks, retail centers, schools, universities, and multi-unit residential complexes.

- High-Security Zones: Ideal for data centers, military installations, and government buildings requiring robust physical barriers and integration with advanced security systems.

In scenarios such as a bustling urban development, the clean lines and customizable colors of a European fence offer an unobtrusive yet effective boundary solution. For remote mining operations or metallurgical sites, its enhanced corrosion resistance ensures reliable performance even when exposed to harsh industrial pollutants and extreme weather conditions, preventing costly security breaches and maintaining operational efficiency.

Vendor Comparison: Evaluating European fence Providers

Selecting the right supplier for a European fence system is critical for project success and long-term value. Key differentiators include manufacturing quality, material sourcing, customization capabilities, and post-sales support. Below is a comparative overview based on typical industry offerings.

Customized Solutions for Unique Project Requirements

While standard configurations of European fence systems offer significant advantages, many B2B projects demand tailored solutions to meet specific site conditions, security threat profiles, and aesthetic preferences. Customization capabilities are a hallmark of a proficient supplier, ensuring optimal integration and performance.

Our expertise allows for extensive customization, including adjustments to panel dimensions (heights and widths), wire diameters for increased anti-cut resistance, and variations in mesh apertures to enhance anti-climb characteristics or optimize visibility. Clients can specify unique RAL color codes for powder coating to align with corporate branding or local architectural guidelines. Furthermore, post configurations can be customized to include specific fixing methods, base plates for concrete mounting, or extended lengths for deeper ground insertion in unstable terrains.

Beyond basic dimensions and aesthetics, advanced customization extends to integrating additional security features. This includes provisions for razor wire or barbed wire extensions, specialized security fasteners to deter tampering, and conduit pathways within posts for seamless integration of CCTV, fiber optic intrusion detection systems, or access control modules. Such bespoke solutions ensure that the European fence acts not merely as a physical barrier but as a comprehensive component of a layered security strategy.

Application Case Studies

The proven performance of European fence systems is best illustrated through real-world applications, demonstrating their adaptability and effectiveness in diverse operational environments.

Case Study 1: High-Security Data Center Perimeter

A leading European cloud service provider required a robust, anti-climb perimeter solution for their new data center. They specified a 2.4m high European fence with 50x100mm mesh and 6mm wire diameter, hot-dip galvanized and powder coated in RAL 7016. The solution included custom-designed posts with integrated conduits for fiber optic intrusion detection cables and CCTV mounts. The project was completed within a 6-week timeframe, providing a physically impenetrable and electronically monitored barrier that met stringent regulatory compliance for data security. The client reported a significant enhancement in perimeter integrity and operational confidence.

Case Study 2: Coastal Industrial Park Fencing

An industrial park located near a coastal region faced persistent issues with corrosion on their existing fencing, leading to high maintenance costs and reduced security. They opted for a specialized European fence system featuring an enhanced hot-dip galvanization (minimum 400 g/m² zinc coating) combined with a marine-grade polyester powder coating. The 2.0m high panels with 50x200mm mesh were installed across 5km of perimeter. After three years, independent inspections confirmed zero signs of corrosion, validating the superior protective qualities and demonstrating significant long-term savings in maintenance and replacement for the park management.

Case Study 3: Urban School Perimeter Upgrade

A municipal education board required a durable, aesthetically pleasing, and safe perimeter solution for a newly constructed urban school. The criteria included robust security without creating an overly institutional feel. A 1.8m high European fence in RAL 6005 (moss green) was chosen, providing secure boundaries for playgrounds and facilities. The modular system allowed for rapid installation during the school holiday period. The clean lines and durable finish enhanced the school's overall appeal while providing reliable safeguarding for students and staff, meeting all safety standards and local regulations.

Trustworthiness, Lead Times, Warranty, and Support

Our commitment to quality, reliability, and customer satisfaction underpins every aspect of our operations. We ensure compliance with the highest industry standards and provide comprehensive support throughout the project lifecycle.

- Certifications: Our manufacturing processes adhere strictly to ISO 9001:2015 quality management systems. Our products also meet relevant European (EN) and American (ASTM) standards for materials and coatings, ensuring consistent, high-grade output. We are proud partners with leading construction and infrastructure firms globally, attesting to our product reliability and service excellence cultivated over decades in the industry.

- Lead Time & Fulfillment: For standard European fence configurations, typical lead times range from 3-4 weeks from order confirmation to dispatch. Custom orders, depending on complexity and material availability, generally require 5-7 weeks. Our robust production capacity and efficient logistics network ensure timely and reliable delivery, minimizing project delays for our B2B clients.

- Warranty Commitments: We provide industry-leading warranties on our European fence products. A standard 10-year warranty covers material defects and coating integrity against corrosion for standard galvanized and powder-coated finishes. Extended warranties of up to 20 years are available for specialized coatings used in harsh environments, demonstrating our confidence in product longevity.

- Customer Support & After-Sales Service: Our dedicated project managers and technical support team are available from initial consultation through to post-installation. We offer expert advice on product selection, site assessment, CAD design services, and detailed installation guidance. After-sales support includes troubleshooting, spare parts provision, and maintenance recommendations, ensuring sustained performance and customer satisfaction.

Frequently Asked Questions (FAQ)

A1: With proper installation and the standard hot-dip galvanized and powder-coated finish, a European fence typically has a service life of 15-25 years, often exceeding this in less aggressive environments. Our extended warranties reflect this exceptional longevity.

A2: The European fence offers significantly higher security. Its rigid welded mesh construction, smaller apertures, and often integrated V-bends make it much harder to cut or climb compared to flexible chain link. The dual-layer coating also provides superior anti-corrosion protection, maintaining structural integrity over decades.

A3: Absolutely. Our European fence systems are designed for seamless integration with a wide range of security technologies, including CCTV cameras, intrusion detection sensors (e.g., fiber optic cables), access control systems, and lighting. Posts can be customized with internal conduits for discreet cable management.

A4: We offer extensive customization for the European fence, including varying panel heights and widths, wire diameters, mesh sizes, and a full spectrum of RAL colors for powder coating. Post types, fixing methods, and additional security elements like barbed wire extensions can also be tailored to specific project needs.

A5: Due to its high-quality construction and superior protective coatings, the European fence requires minimal maintenance. Periodic cleaning may be necessary in certain environments to maintain its aesthetic appeal, but structural integrity and corrosion protection are designed for decades of trouble-free performance.

References

- ISO 9001:2015 - Quality management systems - Requirements. International Organization for Standardization.

- EN 10223-4: Steel wire and wire products for fences and netting - Part 4: Steel wire welded mesh fencing. European Committee for Standardization.

- EN ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles - Specifications and test methods. International Organization for Standardization.

- ASTM A641/A641M - 19a: Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire. ASTM International.

- AkzoNobel Powder Coatings: Interpon D series technical data sheets. AkzoNobel.

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.