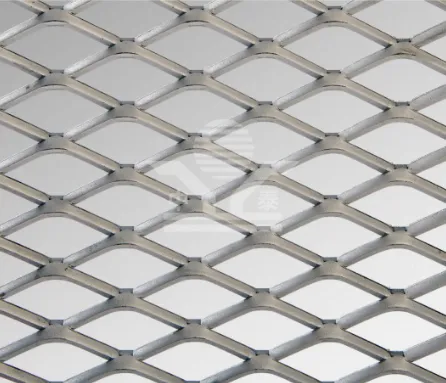

Steel Expanded Metal: a field report from the shop floor and the spec desk

If you work in architecture or plant maintenance, you’ve bumped into Steel Expanded Metal more times than you realize. It shows up as walkways, sunscreens, machine guards—quietly doing the job. I’ve been in factories where it’s cut from coil before your coffee cools, and on jobsites where site managers swear by it because it rarely slips, sags, or surprises.

What’s happening in the market

Demand is quietly shifting toward lighter gauges with higher open-area ratios for airflow and façade transparency. However, heavy-duty catwalk patterns still dominate in petrochem and mining. Many customers say they’re upgrading to stainless or hot-dipped galvanized finishes to extend service life—understandable with capex scrutiny being what it is. And yes, aluminum alternatives are gaining traction for architectural installs where weight and corrosion resistance matter.

Specs that actually matter on site

| Parameter | Typical Range (≈ / real-world may vary) | Notes |

|---|---|---|

| Material | Low-carbon steel, SS304/316; aluminum option | Vendor offers stainless and aluminum variants |

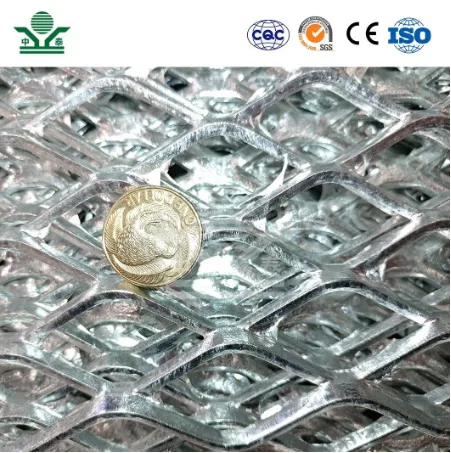

| Thickness | 0.8–6.0 mm | Heavier for platforms/guards |

| Strand Width | 0.5–8 mm | Impacts strength & stiffness |

| SWD × LWD | 10×25 to 40×100 mm diamond | Choose for grip, airflow, opacity |

| Open Area | 35–75% | Drainage vs. strength balance |

| Finish | Mill, HDG, powder coat, anodize (Al) | Corrosion protection drives life |

How it’s made (quick process flow)

Materials: steel coil/plate (ASTM A1011 or A36), stainless (ASTM A240), or aluminum plate. Methods: slitting and simultaneous stretching/expanding; then leveling, cutting, optional edging; surface treatment (HDG to ASTM A123/A153, or powder). Testing: geometry per ASTM F1267, coating thickness via ISO 2178/ASTM B499; load tests to NAAMM/EMMA guidance. Service life: ≈10–25 years outdoors (finish and environment dependent). Industries: construction, energy, OEM guards, filtration, décor.

Applications & advantages

Walkways and platforms (good grip, drainage), machine guarding (rigid, tamper-resistant), façade screens (nice shadows), fencing and cages (fast install), filters and sieving (diamond openings). The big win, to be honest, is efficiency: one piece, no welds, minimal scrap. Many maintenance leads say they chose Steel Expanded Metal for slip resistance and easy cleaning.

Vendor snapshot and comparison

Origin of the featured supplier: No. 12, Jingwu Road, East District, Industrial Park, Anping County, Hengshui, Hebei, China. I’ve toured Anping more than once; the mesh ecosystem there is, frankly, unmatched for speed on custom runs.

| Vendor | Lead Time (≈) | Customization | Certs | Notes |

|---|---|---|---|---|

| Anping maker (this product) | 7–20 days | SWD/LWD/edging, coatings | ISO 9001 (typical) | Competitive MOQs, global ship |

| Global distributor A | Stock: 2–5 days | Cut-to-size only | ISO 9001 | Great for small rush orders |

| Regional fabricator B | 10–30 days | High—weld frames, stairs | ISO 3834, ISO 9001 | One-stop assemblies |

Field notes, tests, and a couple of mini case studies

A food plant in Johor swapped painted mild steel for 316 expanded mesh; washdowns doubled and corrosion complaints dropped to near-zero within a year. Another site in Texas used HDG mesh walkways; measured wet dynamic COF around 0.63 (ASTM F1679 method) and injury incident rates fell—small sample, but telling. Load test on a 3.0 mm, 25×60 mm pattern reached ≈3.8 kN over 300 mm span before permanent set (shop test; your mileage will vary).

Customization checklist

- Specify SWD/LWD and strand width first; strength follows.

- Edge treatments: sheared, flattened, or welded banding for stiffness.

- Finish: HDG for outdoors; powder or anodize for color; stainless for hygiene.

- Compliance: ASTM F1267 geometry, OSHA 1910 guard openings, slip resistance targets.

Final thought? Steel Expanded Metal is one of those no-drama materials that rewards clear specs. Get the mesh geometry and finish right, and it just works.

Authoritative citations

- ASTM F1267 – Standard Specification for Expanded Metal.

- ASTM A123/A153 – Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ASTM A240 – Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip.

- NAAMM/EMMA expanded metal recommendations (industry guidance).

- OSHA 29 CFR 1910 – Walking-Working Surfaces and Machine Guarding.

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.