Understanding Stainless Steel Wire Netting: Industry Trends and Strategic Importance

In an era defined by advanced material science and stringent industrial requirements, the demand for high-performance filtration, separation, and reinforcement solutions is at an all-time high. Central to meeting these demands is Stainless steel wire netting, a versatile product critical across a multitude of B2B sectors. Its inherent properties of corrosion resistance, high tensile strength, and aesthetic appeal position it as an indispensable component in modern engineering and architectural projects.

Current industry trends indicate a robust growth trajectory for stainless steel mesh products. Factors driving this growth include:

- Increasing demand from chemical and petrochemical industries: The need for materials that can withstand aggressive chemical environments and high temperatures is paramount, driving the adoption of specialized stainless steel grades like 316L and Duplex.

- Expansion of the water treatment sector: As global water scarcity issues intensify, sophisticated filtration and screening solutions are essential, where the hygiene and durability of stainless steel are unmatched.

- Growth in the food and pharmaceutical industries: Strict hygiene regulations necessitate materials that are easy to clean, non-contaminating, and corrosion-resistant, making stainless steel an ideal choice for sieving, sorting, and processing.

- Architectural and design innovation: Stainless steel wire netting is increasingly used for modern facades, balustrades, and interior design elements, driven by its sleek appearance and durability.

The market is also seeing innovations in weaving technologies, leading to finer meshes, more consistent apertures, and enhanced material combinations, further expanding application possibilities and performance benchmarks. These advancements ensure that the product continues to meet the evolving demands of a technologically complex world.

Precision Engineering: The Manufacturing Process of Stainless Steel Wire Netting

The production of high-quality Stainless steel wire netting is a meticulous process, combining advanced metallurgy with precision engineering. The objective is to achieve a product with uniform mesh, precise wire diameter, and superior structural integrity, capable of performing reliably in demanding industrial environments. The typical manufacturing flow involves several critical stages:

-

Material Selection and Wire Drawing:

The process begins with selecting high-grade stainless steel raw materials, typically in coil form. Common alloys include AISI 304, 316, 316L, and for highly specialized applications, Duplex stainless steels (e.g., 2205, 2507) or 904L. These materials are chosen for their specific properties such as corrosion resistance, heat resistance, and tensile strength. The raw wire undergoes a cold drawing process where it is pulled through a series of dies to achieve the precise final wire diameter, optimizing its mechanical properties for subsequent weaving or welding.

-

Annealing:

After drawing, the wire may undergo an annealing heat treatment. This process involves heating the wire to a specific temperature and then slowly cooling it, which reduces hardness, increases ductility, and relieves internal stresses, making the wire more pliable and less prone to breakage during weaving or forming.

-

Weaving or Welding:

This is the core manufacturing stage.

- Weaving: Utilizes advanced looms that interlace warp (longitudinal) and weft (transverse) wires to create mesh. Common weave types include plain weave (strong, stable), twill weave (stronger, allows for finer mesh), and various Dutch weaves (for very fine filtration).

- Welding: For welded wire mesh, individual wires are resistance-welded at each intersection. This method produces a very rigid and robust mesh with consistently square or rectangular apertures.

-

Cutting, Shaping, and Fabrication:

The large rolls of woven or welded mesh are then cut to specified dimensions using automated or semi-automated cutting machines. Further fabrication may involve forming the mesh into cylinders, cones, baskets, or other custom shapes through bending, rolling, or CNC machining processes, depending on the final application.

-

Surface Treatment (Optional, but Recommended):

For enhanced performance, especially in highly corrosive or hygienic environments, surface treatments are applied.

- Passivation: A chemical treatment that removes free iron from the surface and forms a passive chromium oxide layer, significantly boosting corrosion resistance.

- Electro-polishing: An electrochemical process that smoothes the surface, removes microscopic imperfections, and further enhances corrosion resistance and cleanability, often used for pharmaceutical and food-grade applications.

-

Quality Control and Testing:

Throughout the process, rigorous quality control measures are implemented. Final product testing often includes: mesh count verification (e.g., to ISO 9044), wire diameter measurement, aperture size uniformity, material composition analysis (XRF), tensile strength tests, and visual inspection for defects. For critical applications, salt spray tests (ASTM B117) are conducted to confirm corrosion resistance.

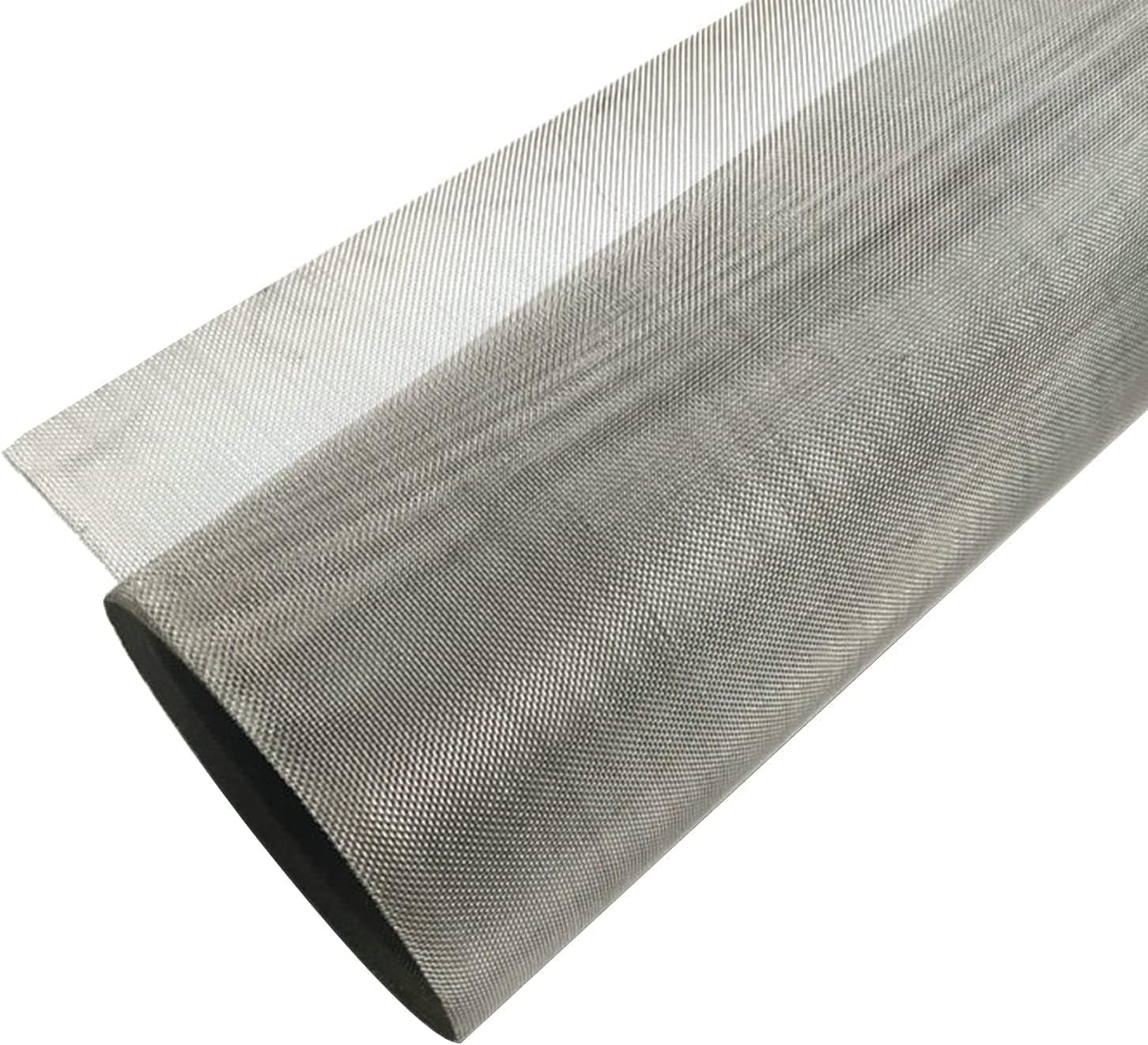

Figure 1: High-precision weaving process for stainless steel wire netting, ensuring uniform mesh and aperture.

Adherence to international standards such as ISO (e.g., ISO 9001 for quality management, ISO 9044 for industrial sieves) and ASTM (e.g., ASTM E2016 for industrial wire cloth) is paramount, ensuring products meet global benchmarks for quality and performance. This meticulous manufacturing process ensures that the finished product offers exceptional advantages in typical application scenarios, such as superior energy saving through efficient filtration, and extended service life due to outstanding corrosion resistance.

Key Technical Specifications and Performance Metrics

Understanding the technical specifications of Stainless steel wire netting is crucial for engineers and procurement specialists to ensure optimal performance in specific applications. These parameters directly influence the product's suitability for filtration, screening, structural support, and corrosive resistance.

Table 1: Typical Stainless Steel Wire Netting Specifications

| Parameter | Description | Typical Range / Values | Significance |

|---|---|---|---|

| Material Grade | Specific stainless steel alloy composition. | 304, 316, 316L, Duplex 2205/2507, 904L | Dictates corrosion resistance, high-temperature performance, and mechanical strength. 316L for enhanced pitting resistance. |

| Mesh Count | Number of openings per linear inch (or cm). | 2 to 635 mesh (0.25 to 0.02 mm aperture) | Determines filtration efficiency and particle size separation capabilities. Higher count = finer mesh. |

| Wire Diameter | Thickness of individual wires. | 0.02 mm to 6.0 mm (varies with mesh count) | Influences mesh strength, open area, and flow rate. Thicker wires provide more strength. |

| Aperture Size | Clear opening between adjacent wires. | 0.02 mm to 25 mm (20 microns to 1 inch) | Crucial for precise sizing, screening, and particle retention in filtration. |

| Weave Type | Pattern in which wires are interlaced. | Plain, Twill, Dutch (Plain/Twill), Five-Heddle, Reverse Dutch | Affects strength, stability, open area, and filter rating. Dutch weaves offer finer filtration. |

| Tensile Strength | Maximum stress the material can withstand before breaking. | 520-720 MPa (for 304/316 depending on condition) | Indicates structural robustness and resistance to deformation under load. |

| Max Operating Temp | Highest temperature for continuous safe operation. | ~870°C (for 304), ~925°C (for 316) | Crucial for high-temperature processes and exhaust systems. |

| Open Area (%) | Percentage of total mesh area that is open (not blocked by wires). | Typically 25% to 80% | Affects flow rate, filtration capacity, and pressure drop across the mesh. |

These specifications are often interdependent. For instance, increasing the wire diameter for a given mesh count will decrease the aperture size and open area, but increase the mesh's overall strength. Engineers must balance these factors to select the most appropriate configuration for their specific application challenges.

Unrivaled Advantages in Diverse Environments

The widespread adoption of Stainless steel wire netting across various industrial sectors is testament to its multifaceted technical advantages. These benefits translate directly into operational efficiencies, cost savings, and enhanced product quality for B2B clients.

-

Superior Corrosion Resistance:

The primary advantage of stainless steel is its exceptional resistance to corrosion, attributed to the passive chromium oxide layer formed on its surface. Different grades offer varying levels of resistance to specific corrosive agents:

- 304 Stainless Steel: Excellent resistance to most oxidizing acids and is widely used in general industrial, food, and architectural applications.

- 316/316L Stainless Steel: Enhanced corrosion resistance due to the addition of molybdenum, making it highly effective against chlorides, sulfuric acid, and other harsh chemicals, ideal for marine, petrochemical, and pharmaceutical environments.

- Duplex Stainless Steels: Offer a combination of high strength and superior corrosion resistance, particularly to stress corrosion cracking and pitting, suitable for offshore and highly aggressive chemical processing.

-

High Temperature Stability:

Stainless steel maintains its mechanical properties and structural integrity at elevated temperatures, far exceeding those of many other materials. This makes it indispensable for applications involving heat treatment, exhaust systems, and high-temperature filtration in metallurgy and chemical processing, where it resists oxidation and creep deformation.

-

Exceptional Durability and Mechanical Strength:

With high tensile strength and abrasion resistance, stainless steel wire netting can withstand significant mechanical stresses, impacts, and abrasive wear. This robustness ensures longevity and consistent performance, even in high-throughput or mechanically demanding applications like vibratory screens in mining.

-

Hygienic and Easy to Clean:

The non-porous surface of stainless steel resists bacterial growth and is easy to sanitize, making it the material of choice for the food, beverage, and pharmaceutical industries where stringent hygiene standards are critical. Its inert nature prevents contamination of processed materials.

-

Dimensional Stability and Precision:

Advanced weaving and welding techniques ensure precise and consistent aperture sizes, which is vital for accurate particle separation and filtration. This dimensional stability is maintained even under thermal cycling or mechanical stress, guaranteeing reliable performance over time.

-

Aesthetic Appeal:

Beyond its functional benefits, stainless steel offers a modern, clean, and professional appearance, making it a favored material in architectural and design applications where aesthetics are as important as performance.

These combined advantages underscore why Stainless steel wire netting represents a strategic investment for industries seeking durable, high-performance, and cost-effective solutions.

Versatile Applications Across Critical Industries

The inherent versatility and robust properties of Stainless steel wire netting enable its application across an expansive range of industries, each benefiting from its specific attributes:

-

Petrochemical and Chemical Processing:

Used extensively for catalyst support grids, filtration of aggressive chemicals, molecular sieves, and separation processes. The corrosion resistance of grades like 316L is crucial for extending the service life of equipment operating with acids, alkalis, and hydrocarbons.

-

Metallurgy and Mining:

Applied in screening and sizing of ores, aggregates, and other raw materials. Vibratory screens, often made from high-strength stainless steel, withstand abrasive conditions and heavy loads in mining operations. Also used in heat treatment furnaces for conveying and support.

-

Water Supply & Drainage / Environmental Engineering:

Serves as filter elements for municipal water treatment, wastewater processing, and desalination plants. Its resistance to biological fouling and corrosive water environments ensures long-term operational efficiency in screens, strainers, and filter cartridges.

-

Food & Beverage Industry:

Essential for hygienic sifting, grading, drying, and conveying of food products. Applications include flour sifters, coffee filters, conveyor belts, and insect screens for processing areas, meeting FDA and similar regulatory standards for material contact.

-

Pharmaceutical and Medical:

Utilized for precise sieving of powders, sterile filtration, and as components in medical devices. The ability to be easily cleaned and sterilized is paramount in these applications.

-

Architectural and Decorative:

Favored for its aesthetic appeal and durability in modern architecture, including building facades, balustrade infill panels, security screens, sun shades, and interior design elements. It offers a blend of functionality and contemporary design.

Figure 2: Custom-fabricated stainless steel wire netting components for industrial filtration systems.

Each application leverages the specific material properties and mesh configurations to deliver tailored solutions that optimize performance, safety, and operational longevity.

Selecting Your Partner: Vendor Comparison and Custom Solutions

When procuring high-quality Stainless steel wire netting, the choice of vendor is as critical as the product's specifications. A reliable partner offers not only superior products but also technical expertise, customization capabilities, and unwavering support. Below is a framework for vendor comparison and a detailed look into customization options.

Table 2: Vendor Comparison Matrix for Stainless Steel Wire Netting Suppliers

| Criteria | ZT Wire Mesh (Example) | Vendor B (Competitor) | Vendor C (Competitor) |

|---|---|---|---|

| Material Quality & Traceability | Premium-grade alloys (304, 316, 316L, Duplex), full material certification, batch traceability. | Standard alloys, limited traceability. | Variable quality, basic material certificates. |

| Manufacturing Precision & Standards | ISO 9001 certified, ASTM E2016 compliant, advanced weaving/welding tech, tight tolerance control. | Basic QC, general industry standards. | Inconsistent precision, minimal standard adherence. |

| Customization Capability | Full customization: mesh, wire dia., dimensions, weave, shapes (cylinders, cones), surface finish, engineering support. | Limited customization to standard sizes/grades. | Minimal customization, off-the-shelf products. |

| Lead Time & Fulfillment | Reliable standard lead times (2-4 weeks), expedited options, global logistics network. | Often delayed, less flexible. | Long, unpredictable lead times. |

| Technical Support & After-Sales | Dedicated engineering consultation, comprehensive post-sales support, robust warranty. | Basic customer service, limited technical expertise. | Minimal or no after-sales support. |

Customized Solutions: Tailored to Your Exact Needs

For many B2B applications, standard off-the-shelf products simply do not suffice. True value is often found in bespoke solutions. A leading supplier will offer extensive customization options, collaborating closely with clients from concept to delivery:

- Material Grade and Alloy Variations: Beyond standard 304/316, access to exotic alloys like Duplex, Super Duplex, or Nickel alloys for extreme conditions.

- Precision Mesh and Wire Diameter: Manufacturing capabilities to produce specific mesh counts with exact wire diameters, optimizing open area and filtration efficiency for a particular particle size distribution.

- Weave Pattern Selection: Tailoring the weave (e.g., plain, twill, various Dutch weaves) to achieve specific characteristics such as increased strength, precise pore size distribution, or improved flow rates.

- Dimensions and Shapes: Fabrication into custom rolls, sheets, discs, cylinders, cones, baskets, or complex 3D forms, including laser cutting and welding for intricate designs.

- Edge Treatments and Reinforcements: Custom edge finishing (e.g., selvage, welded edges, U-channel reinforcement) for easier installation and enhanced durability.

- Surface Finishes: Options for specialized passivation, electro-polishing, or coating for enhanced corrosion resistance, hygiene, or aesthetic requirements.

- Engineering and Prototyping Support: Providing CAD/CAM services, material science consultation, and rapid prototyping to develop and test solutions before full-scale production.

This level of customization ensures that the final product is perfectly matched to the operational demands, extending service life and maximizing performance in even the most challenging industrial settings.

Real-World Impact: Case Studies and Client Success

The practical application of high-quality stainless steel wire netting is best demonstrated through real-world case studies, showcasing its impact on operational efficiency, safety, and longevity for our clients.

Case Study 1: Enhanced Filtration in a Petrochemical Refinery

A major petrochemical client was experiencing premature failure of their existing filtration screens in a sulfuric acid alkylation unit. The screens, made from a lesser-grade stainless steel, were succumbing to severe crevice corrosion and stress corrosion cracking, leading to frequent shutdowns and costly replacements. Our engineering team collaborated with the client to design custom 316L stainless steel wire netting with a specialized Dutch weave pattern. The improved alloy composition and precise weave enhanced both chemical resistance and mechanical stability. Post-implementation, the new screens exhibited over three times the service life of their predecessors, drastically reducing maintenance costs and increasing plant uptime. This project highlighted the critical importance of selecting the correct material grade and weave for highly corrosive environments.

Case Study 2: Optimized Sifting for a Pharmaceutical Manufacturer

A leading pharmaceutical company required ultra-fine and highly consistent sieving screens for powdered active pharmaceutical ingredients (APIs). The challenge was to maintain strict particle size distribution while ensuring absolute material purity and preventing cross-contamination. We provided electro-polished 304L stainless steel wire netting, fabricated into custom-sized vibrating sieve frames. The precise aperture control of our woven mesh minimized oversize particles, while the electro-polished surface ensured no residue accumulation and facilitated effortless, sterile cleaning. This solution not only met stringent FDA guidelines but also significantly improved product consistency and accelerated processing times.

Client Testimonial:

"ZT Wire Mesh has been an invaluable partner. Their deep technical understanding of stainless steel wire netting, combined with their ability to deliver custom solutions on time, has significantly enhanced our operational reliability. Their products consistently exceed our expectations in challenging industrial settings."

Figure 3: Quality assurance and final inspection of finished stainless steel wire netting products.

These examples underscore our commitment to delivering not just a product, but a comprehensive, high-value solution engineered for specific industrial challenges.

Ensuring Trust and Reliability: Certifications, Support, and FAQs

Building long-term B2B relationships requires more than just product excellence; it demands transparency, accountability, and unwavering support. Our commitment to Authoritativeness and Trustworthiness is demonstrated through robust certifications, clear guarantees, and comprehensive customer service.

Certifications and Industry Recognition:

We operate under stringent quality management systems, evidenced by:

- ISO 9001:2015 Certification: Our manufacturing and quality control processes adhere to internationally recognized standards, ensuring consistent product quality and customer satisfaction.

- Adherence to ASTM Standards: Our products meet or exceed relevant ASTM specifications (e.g., ASTM E2016 for Industrial Woven Wire Cloth), guaranteeing material composition and performance.

- Compliance with Industry-Specific Directives: Products for food and pharmaceutical applications comply with relevant directives such as FDA (Food and Drug Administration) material guidelines where applicable.

With over 20 years of experience in the industry, we have cultivated partnerships with leading engineering firms, major industrial contractors, and global manufacturers, establishing a reputation for reliability and innovation. All products are delivered with comprehensive test reports and material certificates, ensuring full traceability and verified performance.

Frequently Asked Questions (FAQ):

Q: What is the primary difference between 304 and 316 Stainless steel wire netting?

A: The main difference lies in the chemical composition, specifically the addition of molybdenum in 316 stainless steel. This addition provides 316 stainless steel wire netting with superior resistance to pitting and crevice corrosion, especially in chloride-rich environments like marine settings or chemical processing. While 304 is excellent for general applications, 316/316L is preferred for more aggressive corrosive conditions.

Q: How do I choose the correct mesh count and wire diameter for my application?

A: This depends on the specific requirements of your application, primarily the desired filtration or separation size. Fine mesh counts (higher numbers) with smaller wire diameters are suitable for precision filtration. Coarser mesh counts with larger wire diameters offer greater strength and open area for screening larger particles or structural support. Our technical team can provide detailed consultation based on your process parameters.

Q: Can your Stainless steel wire netting products be used in high-temperature environments?

A: Yes, stainless steel generally exhibits good high-temperature resistance. For instance, 304 can be used up to approximately 870°C and 316 up to 925°C for continuous service in certain conditions, resisting oxidation and maintaining mechanical strength. For extreme temperatures, specialized high-nickel alloys or heat-resistant stainless steels can be utilized.

Q: What are your typical lead times for custom orders?

A: Standard lead times for common specifications typically range from 2 to 4 weeks. For highly customized or large-volume orders, lead times may vary. We offer expedited manufacturing and shipping options for urgent projects and work closely with clients to meet critical deadlines.

Warranty Commitments and Customer Support:

We stand behind the quality of our Stainless steel wire netting products with a comprehensive warranty against manufacturing defects and material flaws. Specific warranty periods and terms are provided with each order, typically extending for several years from the date of purchase.

Our dedicated customer support team and technical experts are available for pre-sales consultation, engineering assistance, and post-sales support. This includes helping with product selection, installation guidance, and troubleshooting to ensure optimal performance and client satisfaction throughout the product's lifecycle. We are committed to fostering long-term partnerships built on trust and mutual success.

Conclusion

The strategic importance of high-quality Stainless steel wire netting in modern industrial and architectural applications cannot be overstated. Its unmatched combination of corrosion resistance, mechanical strength, thermal stability, and hygienic properties positions it as a premier material for critical filtration, separation, and structural tasks across diverse sectors. From the rigorous demands of petrochemical processing and metallurgy to the stringent hygiene requirements of food and pharmaceutical manufacturing, and the aesthetic needs of contemporary architecture, stainless steel wire netting offers reliable, durable, and cost-effective solutions.

By leveraging precision manufacturing processes, adherence to international quality standards, and a deep commitment to customized solutions and client support, we ensure that our products not only meet but exceed the demanding expectations of B2B decision-makers and engineers. Partnering with a trusted supplier guarantees access to expert consultation, innovative product development, and consistent performance that drives operational efficiency and long-term value.

References

- ASM International. (2001). ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys. ASM International.

- NACE International. (2018). Corrosion Engineering: Principles and Practice. NACE International.

- Stainless Steel World. (Ongoing). Technical Articles & Industry Insights. KCI Publishing BV.

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.