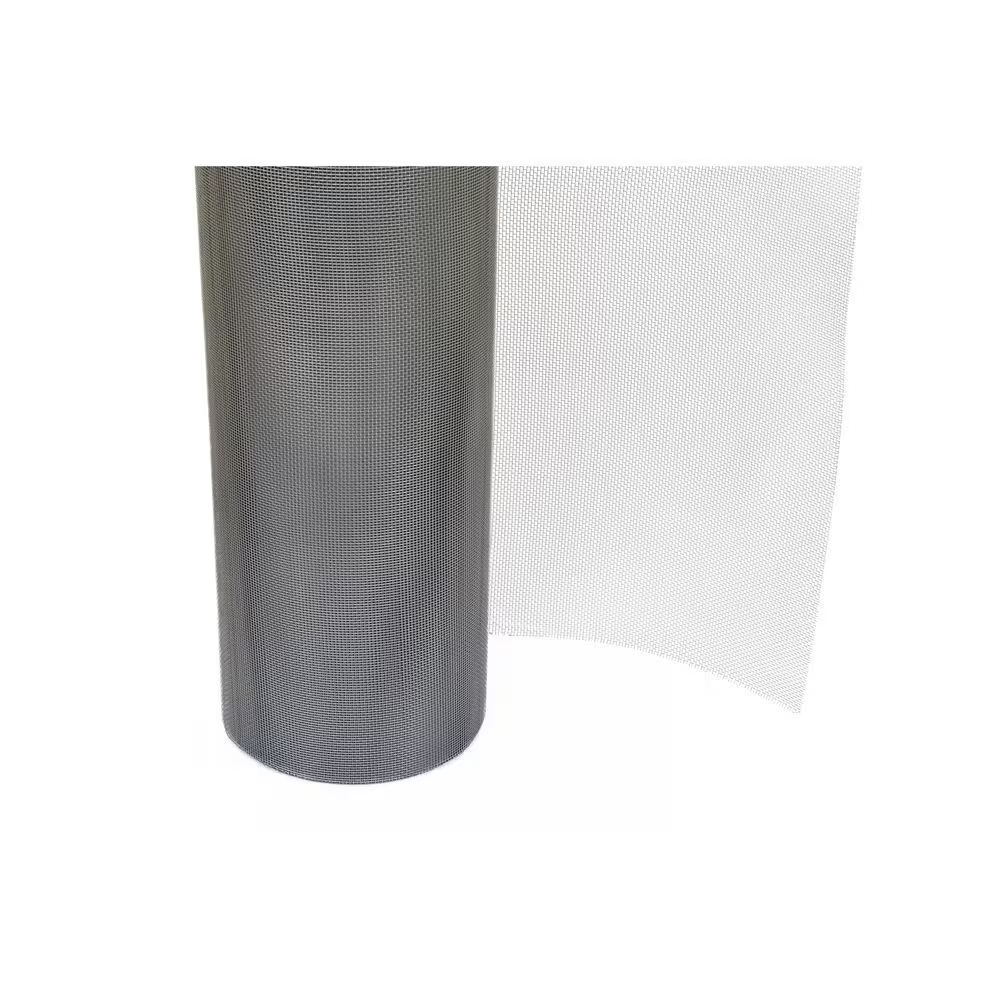

A Field Note on Stainless steel wire netting : specs, trends, and real-world use

I’ve toured enough mills and coastal job sites to know one thing: when insects, corrosion, and wind pressure all gang up on a building, plain aluminum screens tap out early. That’s where Stainless steel wire netting quietly earns its keep—stronger, cleaner edges, and, to be honest, better over time in tough climates. Origin-wise, the material discussed here ships from No. 12, Jingwu Road, East District, Industrial Park, Anping County, Hengshui, Hebei, China—an area that’s basically the global nerve center for wire mesh.

What it is (and why buyers are switching)

It’s a woven or welded metal screen made from stainless steel wires (304/316/316L are the usual suspects). Compared with fiberglass or aluminum, Stainless steel wire netting resists denting, holds tension better, and shrugs off coastal air. Many customers say they picked it for security doors and hurricane-prone openings—and stayed for the clean look.

Industry trends

- Coastal projects: rising demand for 316/316L due to salt spray.

- Fine mesh for passive-house ventilation and insect control without big airflow penalties.

- Food, pharma, and cleanroom retrofits asking for traceability and ISO 9001-backed QA.

Process flow and testing (the short version)

Materials: SS304 for general use; SS316/316L for marine or chemical environments; SS430 where magnetism is acceptable and budgets are tight.

Methods: wire drawing → annealing → weaving (plain/twill) or spot welding → leveling → edge trimming → degrease/passivation → final tensioning and inspection.

Testing standards used by better shops: ASTM E2016 (woven wire cloth), ISO 9044 (industrial wire screens), ASTM A580/A580M (stainless wire), and salt spray per ASTM B117 or ISO 9227. In fact, reputable vendors log mesh count, wire diameter tolerance, tensile strength, flatness, and burr checks. Service life? Around 10–20 years in normal urban use; coastal exposure varies with grade and maintenance.

Typical product specs

| Grade | Mesh (per inch) | Wire Ø (mm) | Aperture (mm) | Open Area ≈ | Weave/Finish | Standards |

|---|---|---|---|---|---|---|

| SS304 | 18×16 | 0.25 | ≈1.15 | ≈65% | Plain / Bright | ASTM E2016 |

| SS316 | 20×20 | 0.23 | ≈1.02 | ≈64% | Plain / Passivated | ISO 9044 |

| SS316L | 30×30 | 0.18 | ≈0.67 | ≈40–50% | Plain / Matte | ASTM A580 |

Note: values are typical; real-world use may vary by batch and tension settings.

Where it’s used (a few quick scenarios)

- Windows and security doors in coastal apartments (316/316L preferred).

- Food plants and clinics seeking cleanability and low lint.

- Vent and soffit screens for insect control without ugly sagging.

- HVAC intakes and light-duty filtration; greenhouses that hate rust.

Two fast case notes

- Marina retrofit, Florida: swapped aging aluminum with 316L plain weave; after 1 year of ISO 9227-equivalent exposure checks, no red rust and minimal tea staining at cut edges (cleaned quarterly). The facility manager—who was skeptical—now wants it on stair enclosures.

- Bakery packaging area, EU: chose SS304 passivated, 20×20 mesh; wipe-down sanitation improved and mesh held tension better vs. fiberglass screens, reducing replacements by about a third (their words, not mine).

Vendor snapshot (what buyers usually compare)

| Vendor | Origin | MOQ | Lead Time ≈ | Certs/QA | Customization | Notes |

|---|---|---|---|---|---|---|

| ZT Wire Mesh | Anping, Hebei | ≈ 10 rolls | 10–20 days | ISO 9001; ASTM/ISO testing logs | Mesh, width, grade, passivation | Strong coastal track record |

| Marketplace Supplier A | Mixed | Low (varies) | 7–30 days | Claims vary | Limited options | Check wire grade provenance |

| Local Fabricator B | Domestic | Small | Fast on stock | Shop QA | Cut-to-size frames | Great for quick replacements |

Buying tips, quickly

- For salty air, pick 316/316L and ask for passivation records.

- Verify mesh count and wire diameter against ASTM E2016 or ISO 9044.

- Request basic salt-spray or at least material certs per ASTM A580.

Citations

- ASTM E2016 – Standard Specification for Industrial Woven Wire Cloth.

- ISO 9044 – Industrial wire screens and woven wire cloth — Technical requirements and tests.

- ASTM A580/A580M – Standard Specification for Stainless Steel Wire.

- ASTM B117 / ISO 9227 – Salt spray (fog) testing for corrosion resistance.

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.