Field Notes on Serrated Grating: Safer Walkways, Cleaner Budgets

If you’ve spent time on industrial catwalks in the rain, you already know why serrated galvanized grating keeps winning specs. It’s bluntly practical: bite for boots, drainage for grime, zinc for longevity. Our team in Anping (No. 12, Jingwu Road, East District, Industrial Park, Anping County, Hengshui, Hebei, China) ships globally, and—honestly—most customers just want fewer slips and fewer shutdowns. Hard to argue with that.

What’s trending right now

There’s a tilt toward higher slip ratings and traceable QC. Zinc prices wobble; buyers shift to lifecycle cost thinking, not just cheapest per kg. Add-ons like kick plates, integral nosing, and BIM-ready models are standard-ish now. ESG folks push recyclability—steel helps; and for corrosive zones, GRP panels still have a place. Actually, many facilities mix both: steel for heavy loads, GRP for chemical areas.

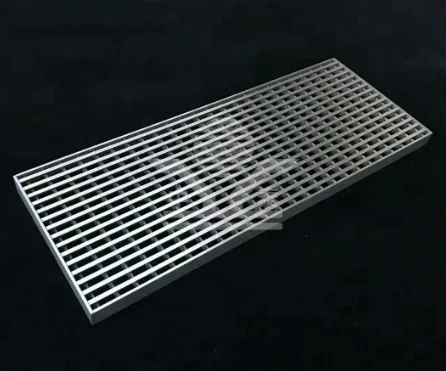

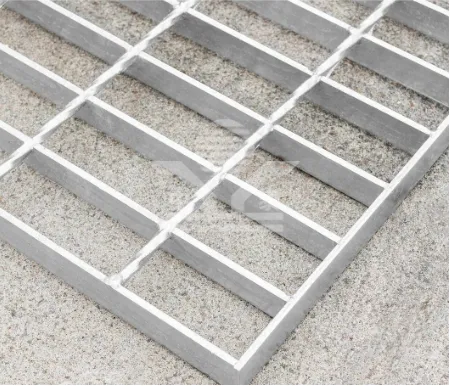

Product snapshot: Metal Grid Walkway China Suppliers GRP Floor Grating

Certified lines available: BSCI, CCC, CE, FCC, GS, ISO, RoHS, SAA. Typical uses: steel structure walkway, foot pedal, drain cover. Standard “flat” profile, with serrated bearing bars for anti-slip. Below are common specs for serrated galvanized grating used in industrial walkways.

| Material | Q235/Q345 carbon steel; optional 304/316L for special zones |

| Bearing bar size | 25×3, 32×5, 40×5 mm (others on request) |

| Bar pitch / cross pitch | 30–40 mm / 50–100 mm |

| Serration depth | ≈1.5–2.0 mm for bite in wet/oily conditions |

| Coating | Hot-dip galvanized per ISO 1461/ASTM A123; ≈70–100 μm zinc (around 460–700 g/m²) |

| Load guide | UDL ≈5 kN/m² @ 1 m span; point load data on request (real-world use may vary) |

How we build it (short version)

- Materials: slit coil to bearing bars; twist or round cross bars.

- Forming: serration roll; resistance-weld or pressure-lock grids.

- Fabrication: cut-to-size, toe plates, checker nosing, edge banding.

- Galvanizing: hot-dip per ISO 1461/ASTM A123; quench, passivate.

- Testing: coating thickness (ISO 1461), salt spray checks (ASTM B117), load/deflection vs. NAAMM MBG, slip class per DIN 51130/AS 4586.

- Service life: ≈20–30 years in C2–C3 atmospheres; derate in coastal C4–C5.

Where it works best

serrated galvanized grating shows up on refinery platforms, wastewater walkways, power plant mezzanines, food plants (washdown zones), and municipal drain covers. Many customers say the serrations “just feel safer” underfoot—especially with oil mist or algae.

Vendor snapshot (typical market view)

| Vendor | FOB price | Lead time | QC & Standards | Customization |

|---|---|---|---|---|

| Our Anping plant | ≈$0.95–$1.25/kg | 7–15 days | ISO 1461, ASTM A123; slip test report on request | CNC cut, toe plates, custom spans |

| Supplier A (Jiangsu) | ≈$0.90–$1.10/kg | 10–20 days | ISO 1461; basic load sheet | Standard panels, limited fabrications |

| Trading house (overseas) | ≈$1.10–$1.45/kg | 20–35 days | Varies; request mill certs | Depends on mill slot |

Quick case note

Petchem turnaround, humid coastal site: swapped painted plate for serrated galvanized grating with 32×5 mm bars. Post-install feedback: reported near-misses down 62% in first 6 months; zinc thickness measured ≈86 μm average; point load 4 kN at 900 mm span deflection

Customization and paperwork

- Cut-to-fit panels, curved trays, stair treads with checker or cast nosing.

- Kick plates, galvanizing per ISO 1461 or AS/NZS 4680; optional powder topcoat.

- Cert bundle: BSCI/CCC/CE/FCC/GS/ISO/RoHS/SAA as applicable.

Note: Specs above are indicative; final design should reference NAAMM MBG/EN platforms, site loads, and local codes. Real-world performance can vary with environment and maintenance.

Authoritative references

- ISO 1461: Hot dip galvanized coatings — Requirements and test methods.

- ASTM A123/A153: Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- NAAMM MBG 531: Metal Bar Grating Manual (design and loading guidance).

- OSHA 1910 Subpart D: Walking-Working Surfaces (US safety rules).

- DIN 51130 / AS 4586: Slip resistance classification of pedestrian surfaces.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.