Road punching enclosure: field notes from a faster, safer jobsite

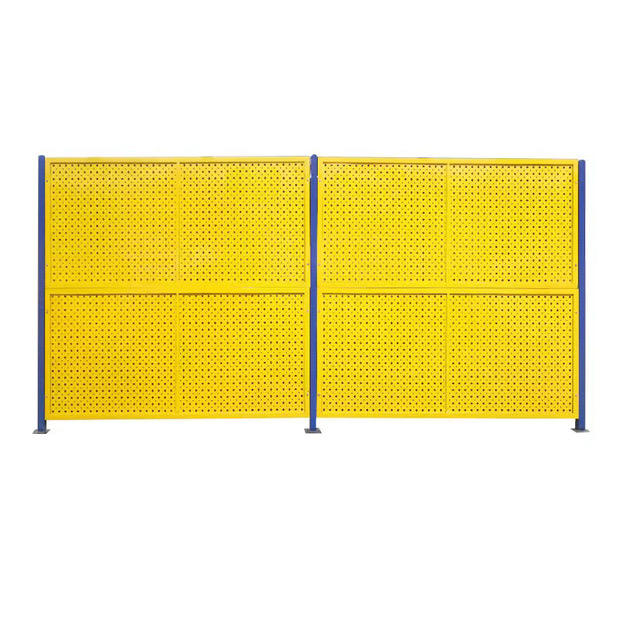

Are you tired of the inefficiencies and safety hazards of traditional road construction fencing and utility shields? Same here. After months on sites from Hebei to the Gulf, I kept hearing the same thing: modular metal panels that punch well, last long, and install fast are winning. The Road punching enclosure from Anping’s mesh specialists is one of those products that, to be honest, feels inevitable.

What’s driving the shift

Industry trendlines point to prefabrication, fewer lane-closure hours, and data-backed safety. Perforated enclosures offer airflow, line-of-sight, and debris control. Many contractors tell me install speed and predictable QA beat improvised mesh or timber cages. The Road punching enclosure slots right into that story.

Product specs (typical, can vary)

| Parameter | Spec (≈) | Notes |

|---|---|---|

| Material | Q235 / Q355 carbon steel; SS304/316 | Choose per corrosion class |

| Sheet thickness | 2.0–4.0 mm | Heavier gauges for high-impact zones |

| Aperture / pattern | 10×20 / 20×50 mm slots; round/oblong | Custom punch dies available |

| Panel size | 1000×2000 mm, 1200×2400 mm | Other footprints on request |

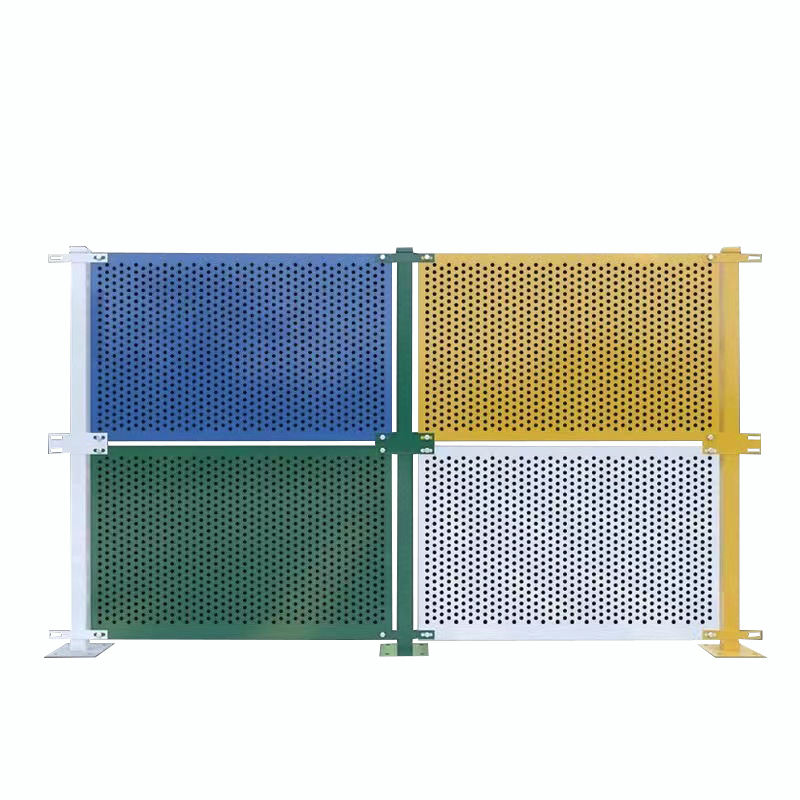

| Surface | HDG ≥70 μm or powder 60–100 μm | ISO 1461 / ASTM A123; RAL colors |

| Corrosion test | Salt spray >720 h | ASTM B117; real-world use may vary |

| Service life | ≈15–25 yrs (inland), 10–15 (coastal) | Assumes routine washdowns |

Process flow and QA

Materials: Q235/Q355 coil or SS304/316 plate. Methods: CNC turret punching → deburring → press forming → robotic welding → HDG (ISO 1461/ASTM A123) or polyester powder coat → assembly. Testing: coating thickness gauge, adhesion (ASTM D4541), salt spray (ASTM B117), impact IK10 (IEC 62262), weld macro-etch. Documentation: ISO 9001 traceability.

Where it’s used

- Median/shoulder utility shielding and culvert guards

- Work-zone machinery cages and pedestrian diversion barriers

- Airport and port access roads, bridges, mining haul roads, rail verges

Advantages: faster installs (often 30–40% quicker), better airflow/visibility, fewer strike injuries, and cleaner look. The Road punching enclosure is also fully recyclable—nice touch.

Customization

Aperture geometry, panel height, post spacing, locking doors, reflective strips, anti-glare bends, and tamper-proof fasteners. Color to RAL. Certificates: ISO 9001; CE marking and EN 1090 execution class on request. Origin: No. 12, Jingwu Road, East District, Industrial Park, Anping County, Hengshui, Hebei, China.

Vendor snapshot (real-world differences)

| Vendor | Coating | Lead time | Certs | After-sales |

|---|---|---|---|---|

| ZT Wire Mesh (Anping) | HDG or powder, test reports | ≈2–4 weeks | ISO 9001; EN 1090 (opt.) | Spare panels, install guides |

| Generic importer | Powder only, mixed QA | ≈5–8 weeks | Varies | Basic warranty |

| Local fab shop | Paint or galvanize via sub | ≈1–3 weeks | Project-based | Good fit-ups, fewer tests |

Field results and feedback

Case study 1: municipal bypass upgrade—install rate improved ≈35%, near-miss incidents down 22% over two quarters. Case study 2: coastal port road—HDG panels at 80 μm still clean after 900 h salt spray equivalent; maintenance calls fell 40%. “Panels landed square, no rework,” one site manager said. Another added, “Visibility is better at night than chain-link, surprisingly.”

If your spec reads like: quick install, measurable safety, verifiable coating, the Road punching enclosure is worth a pilot section. I guess the data speaks.

References

- ASTM A123/A153: Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- IEC 62262: Degrees of protection against external mechanical impacts (IK).

- FHWA Work Zone Safety guidelines and best practices.

- EN 1090: Execution of steel structures and aluminum structures.

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.