Introduction to High-Security Perimeter Solutions

In an era where robust security infrastructure is paramount, the selection of perimeter fencing plays a critical role in safeguarding assets, personnel, and sensitive sites. The evolution of security threats necessitates advanced fencing solutions that offer not only physical deterrence but also resistance against sophisticated breach attempts. Among these, the 358 Security Fence stands out as a leading choice for high-security applications, renowned for its formidable anti-climb and anti-cut properties. Its unique design, characterized by a tight mesh aperture, effectively thwarts penetration attempts, making it an indispensable component of modern security strategies across various industries.

This comprehensive overview delves into the technical intricacies, manufacturing excellence, diverse applications, and inherent advantages of this specialized fencing system, providing B2B decision-makers with the insights needed to make informed procurement decisions for their critical infrastructure projects.

Industry Trends and Market Dynamics in High-Security Fencing

The global security fencing market is experiencing significant growth, driven by escalating security concerns, increasing investment in critical infrastructure, and stricter regulatory compliance. Projections indicate a compound annual growth rate (CAGR) of over 6% for the high-security fencing segment, with market valuation expected to reach approximately $7 billion by 2027. Key trends shaping this market include:

- Integration of Smart Technologies: The emergence of smart fencing solutions, incorporating sensors, CCTV, and access control systems, is enhancing perimeter security beyond physical barriers.

- Demand for Anti-Climb and Anti-Cut Solutions: Industries are increasingly prioritizing fences that are exceptionally difficult to breach, a need perfectly addressed by systems like the 358 Security Fence.

- Sustainability and Durability: A focus on longer service life and environmentally friendly coating processes is becoming standard, reducing maintenance costs and ecological footprint.

- Customization: Growing demand for tailor-made solutions to meet specific site requirements, threat profiles, and aesthetic considerations.

This robust market environment underscores the importance of specifying high-performance, resilient fencing, making solutions like 358 Security Fence increasingly vital for modern security architecture.

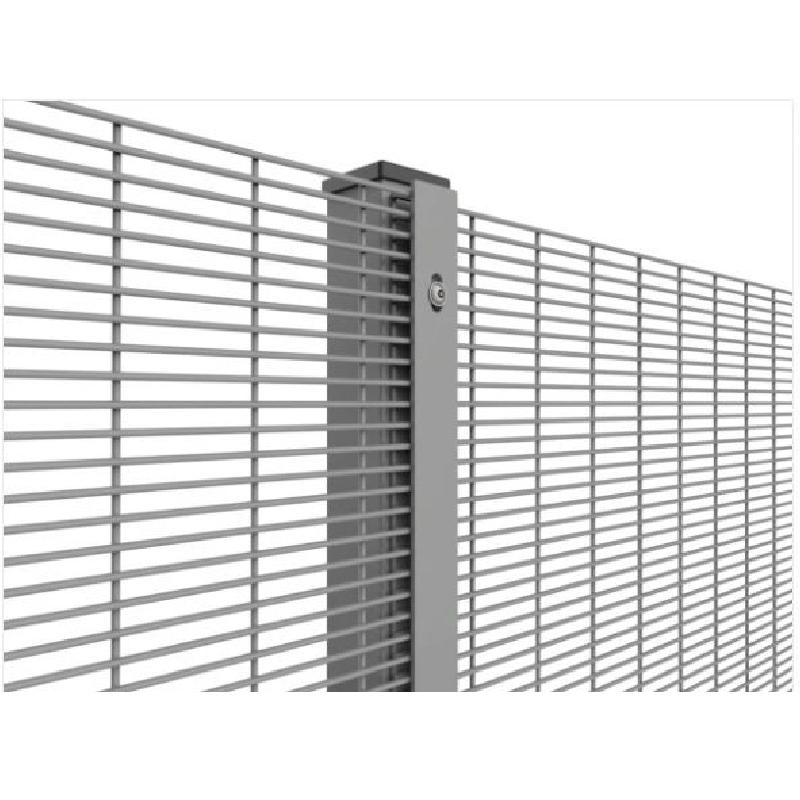

Technical Specifications and Construction of 358 Security Fence

The designation "358" refers to the mesh aperture: 3 inches x 0.5 inches x 8 gauge wire, which translates to approximately 76.2mm x 12.7mm x 4mm wire diameter. This incredibly small mesh opening is the core of its anti-climb and anti-cut capabilities.

Core Specifications

| Parameter | Typical Specification | Technical Detail |

|---|---|---|

| Mesh Aperture | 76.2mm x 12.7mm (3" x 0.5") | Prevents finger and foot holds, making climbing extremely difficult. |

| Wire Diameter | 4.0mm (8 Gauge) | High tensile steel, offering resistance against cutting tools. |

| Panel Height | 1.8m to 6.0m (customizable) | Adaptable for various security requirements, from standard to ultra-high. |

| Panel Width | 2.5m to 3.0m | Optimized for structural integrity and installation efficiency. |

| Material | High-grade steel wire | Ensures structural strength and long-term performance. |

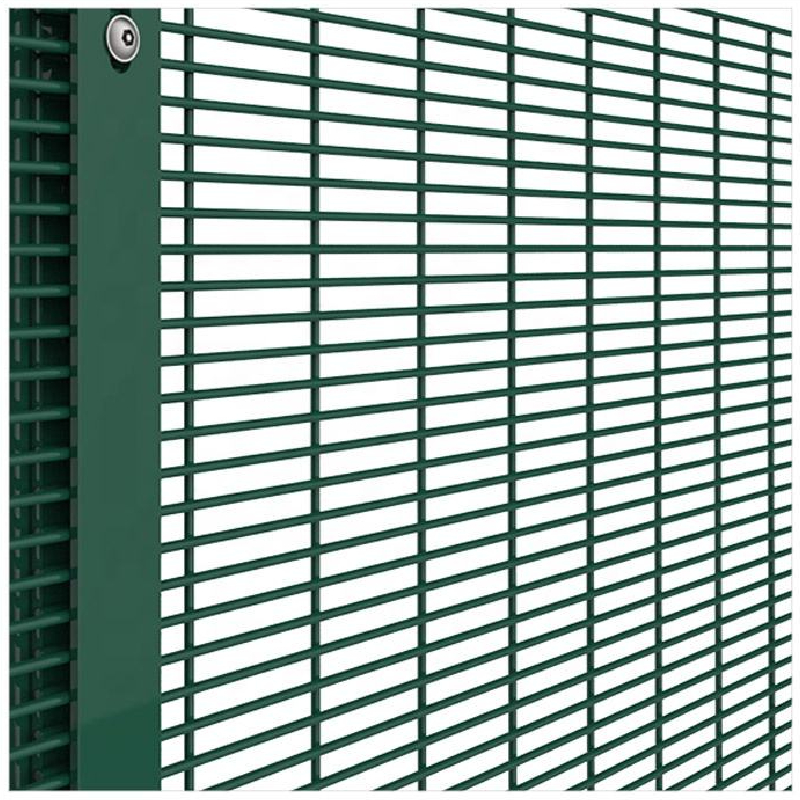

| Surface Treatment | Hot-dip Galvanized, Powder Coated (RAL colors), PVC Coated | Provides superior corrosion resistance and aesthetic integration. |

| Post System | Square hollow section (SHS), Rectangular hollow section (RHS), or C-post | Designed for maximum panel rigidity and resistance to forced entry. |

The robust construction of the 358 Security Fence, combined with various anti-tamper fixings and extensions like barbed wire or razor wire, creates an impenetrable barrier against unauthorized access. The tight mesh also offers excellent visibility, crucial for CCTV monitoring and surveillance, without compromising security.

Manufacturing Process: Precision Engineering for 358 Security Fence

The production of a high-quality 358 Security Fence involves a meticulously controlled, multi-stage process, ensuring durability, strength, and adherence to international standards.

Process Flow

-

1. Material Sourcing & Wire Drawing: High-carbon or low-carbon steel rods are selected for their tensile strength. These rods undergo a wire drawing process, reducing their diameter to the precise 4.0mm (8 gauge) required, enhancing their strength and flexibility.

Material: High-tensile low-carbon steel wire (e.g., Q195, Q235, or equivalent). Adheres to ASTM A641/A853 standards.

-

2. Precision Welding: The drawn wires are then precisely positioned and joined using advanced automated resistance welding machines. This creates the characteristic 76.2mm x 12.7mm mesh aperture. Each intersection is welded to form a rigid, unyielding panel.

Process: Automated resistance spot welding, ensuring uniform weld strength (typically >50% of wire tensile strength) across all intersections.

- 3. Panel Straightening & Trimming: Post-welding, panels are meticulously checked for straightness and flatness. Any excess wire is trimmed to ensure clean edges and dimensional accuracy.

-

4. Surface Treatment (Corrosion Protection): This is a critical stage for longevity.

- Hot-dip Galvanization: Panels are immersed in molten zinc (450°C), creating a metallurgical bond that offers sacrificial cathodic protection against rust. Coating thickness typically meets ISO 1461 or ASTM A123 standards, providing 15-20 years of service life in moderate environments.

- Powder Coating: Electrostatically applied polymer powder is cured at high temperatures, forming a durable, aesthetically pleasing, and corrosion-resistant layer. Often applied over galvanization for dual protection. Adheres to ISO 12944-6 standards, offering enhanced corrosion resistance and UV stability.

- PVC Coating: Panels are coated with a layer of Polyvinyl Chloride, offering superior protection against aggressive chemicals and extreme weather conditions.

Testing: Coating thickness gauges, adhesion tests (cross-cut, pull-off), salt spray tests (ASTM B117) for corrosion resistance. Service life for well-coated fences often exceeds 25 years.

- 5. Quality Control & Final Inspection: Throughout the process, panels undergo rigorous quality checks for mesh dimensions, wire diameter, weld integrity, coating thickness, and overall finish. This ensures compliance with international standards (e.g., ISO 9001:2015 for manufacturing quality, relevant ASTM standards for materials and coatings).

The emphasis on high-grade materials and advanced manufacturing techniques ensures the inherent strength and extended service life of each 358 Security Fence panel, making it a reliable investment for long-term security needs. The sophisticated surface treatment processes are particularly advantageous in environments requiring exceptional corrosion resistance, such as coastal areas or industrial zones exposed to chemical agents.

Technical Advantages and Performance Metrics

The design and material science behind the 358 Security Fence confer several distinct technical advantages, optimizing its performance in critical security applications.

- Superior Anti-Climb Capability: The small mesh aperture (76.2mm x 12.7mm) effectively prevents individuals from gaining finger or toe holds, rendering the fence virtually impossible to climb without specialized equipment. This "prison mesh" design is a cornerstone of its high-security rating.

- Robust Anti-Cut Resistance: The use of 4.0mm (8 gauge) high-tensile steel wire, combined with the dense mesh pattern, makes the fence extremely difficult to cut with standard hand tools like bolt cutters or wire snips. Multiple cuts are required, significantly increasing the time-to-breach.

- High Visibility and Surveillance Compatibility: Despite its strength, the open mesh design allows for excellent line-of-sight through the fence, facilitating unobstructed CCTV surveillance and visual monitoring, which is crucial for perimeter security.

- Exceptional Corrosion Resistance: Through hot-dip galvanization and subsequent powder or PVC coating, the fence achieves outstanding resistance to rust, weathering, and UV degradation. This ensures a long service life, typically exceeding 20-25 years, minimizing maintenance costs and maximizing return on investment. This corrosion resistance is particularly vital in harsh industrial, petrochemical, and marine environments.

- Structural Rigidity: The fully welded mesh matrix and robust post systems (often secured with anti-tamper bolts) provide high resistance to impact and deformation, maintaining structural integrity even under attack.

- Aesthetic Integration: Available in various RAL colors, the fence can be blended into different environmental or architectural contexts, offering an unobtrusive yet highly secure barrier.

These combined attributes make the 358 Security Fence a preferred choice for applications demanding uncompromising security performance and longevity.

Application Scenarios and Case Studies

The unparalleled security features of the 358 Security Fence make it suitable for a wide array of high-stakes environments, spanning numerous target industries.

Target Industries:

- Petrochemical & Energy: Refineries, power plants, solar farms, and gas storage facilities require robust perimeter security to prevent sabotage and theft. The corrosion resistance and anti-climb features are critical in these often hazardous environments.

- Data Centers & IT Infrastructure: Protecting sensitive digital assets from physical intrusion is paramount. The fence provides a formidable physical barrier, often integrated with advanced electronic security systems.

- Military & Defense: Used for military bases, training grounds, and secure government facilities where perimeter integrity is non-negotiable.

- Correctional Facilities: Widely employed in prisons and detention centers due to its high anti-climb effectiveness, significantly reducing escape attempts.

- Transportation Hubs: Airports, seaports, and railway depots utilize this fencing for secure boundary protection, preventing unauthorized access to critical areas.

- Critical Infrastructure: Water treatment plants, telecommunications sites, and nuclear facilities benefit from its enhanced security attributes.

Application Case Studies:

Case Study 1: High-Security Data Center in Northern Europe

A leading cloud service provider required an uncompromising perimeter solution for its new data center in a harsh, cold climate. They opted for a 3.6m high 358 Security Fence, hot-dip galvanized and then powder-coated in dark grey. The client reported a significant increase in perceived security and zero successful perimeter breaches since installation, noting the fence's exceptional resistance to both climbing and cutting attempts, even during extreme weather conditions. The fence also seamlessly integrated with their existing CCTV and motion sensor systems due to its high visibility.

Case Study 2: International Airport Perimeter Expansion

An international airport needed to expand its perimeter security around a new cargo terminal. The existing chain-link fence was deemed insufficient. The airport chose a 5.2m high 358 Security Fence with an additional 1.2m razor wire topping. The project manager praised the fence's rapid installation and its immediate impact on deterring unauthorized access. The tight mesh prevented objects from being passed through and provided an ideal platform for integrated fiber-optic intrusion detection cables. This solution met stringent aviation security regulations and contributed to enhanced operational safety.

Customized Solutions for Diverse Security Needs

Understanding that every security project presents unique challenges, manufacturers offer extensive customization options for the 358 Security Fence. These tailored solutions ensure optimal performance and seamless integration with existing infrastructure.

- Height and Width Variations: Panels can be fabricated to custom heights, ranging from 1.8m to over 6m, and widths, to accommodate specific site layouts and threat levels.

- Coating and Color Options: Beyond standard galvanization, a wide palette of RAL powder coating colors allows for aesthetic integration or high-visibility requirements. Specialized anti-graffiti coatings are also available.

- Post and Fixing Systems: Various post profiles (SHS, RHS, C-Post) and anti-tamper fixing methods (shear-nut bolts, non-removable clamps) can be chosen to match the security rating and structural demands of the site.

- Integration with Security Enhancements: The fence panels are designed to be readily integrated with additional security features such as:

- Razor wire or barbed wire toppings

- PIDS (Perimeter Intrusion Detection Systems) - e.g., fiber optic sensors, microphonic cables

- CCTV cameras and thermal imaging equipment mounts

- Access control gates and turnstiles

- Electric fence energizers

- Ground Conditions Adaptation: Solutions for varying ground conditions, including base-plated posts for concrete surfaces or extended posts for deep embedment in soft soil, ensure stable and secure installation.

Working with experienced manufacturers allows clients to define precise specifications, ensuring a truly bespoke security solution that maximizes protection while adhering to budgetary and operational constraints.

Vendor Comparison: Evaluating High-Security Fencing Options

When specifying high-security fencing, it is crucial to compare the performance, cost-effectiveness, and suitability of various systems. The 358 Security Fence offers a unique balance of security, visibility, and value when compared to other common fencing types.

Comparison Table: 358 Security Fence vs. Alternatives

| Feature | 358 Security Fence | Chain Link Fence (Standard) | Welded Mesh Fence (656/868) | Palisade Fence |

|---|---|---|---|---|

| Security Level (Anti-Climb/Cut) | Very High (No footholds, extremely difficult to cut) | Low (Easy to climb, cut) | Medium (Can be climbed, cut with effort) | High (Difficult to climb, but can be scaled/breached with tools) |

| Visibility for Surveillance | Excellent | Good | Good | Poor (solid pales obscure view) |

| Material & Finish Options | High-tensile steel, HDG + Powder/PVC | Galvanized steel, PVC coated | Steel, HDG + Powder | Galvanized steel, Powder coated |

| Lifespan (Typical) | 20-25+ years | 10-15 years | 15-20 years | 20-25+ years |

| Cost (Relative) | High (Due to superior security features) | Low | Medium | High |

| Typical Applications | Prisons, Airports, Data Centers, Power Plants | General residential, low-security commercial | Schools, parks, commercial perimeters | Industrial sites, utility compounds (where visibility is not critical) |

While the initial investment for a 358 Security Fence may be higher than some alternatives, its superior security performance, extended lifespan, and minimal maintenance requirements often translate into a lower total cost of ownership (TCO) over its operational life. This makes it a strategically sound investment for assets requiring the highest level of protection.

Quality Assurance, Certifications, and Authoritative References

Adherence to rigorous quality standards and industry certifications is paramount in the high-security sector, ensuring that products like the 358 Security Fence meet specified performance criteria and deliver on their promise of protection.

Certifications and Compliance:

- ISO 9001:2015: Certified manufacturers demonstrate a robust quality management system, ensuring consistent product quality from raw material sourcing to final inspection.

- ASTM International Standards: Compliance with relevant ASTM standards (e.g., ASTM F2781 for Welded Wire Mesh Fence Fabric, ASTM A641 for Zinc-Coated (Galvanized) Carbon Steel Wire, ASTM A123 for Zinc (Hot-Dip Galvanized) Coatings) signifies adherence to material composition, coating quality, and performance benchmarks.

- BS EN Standards: European standards such as BS EN 10223-4 (Steel wire and wire products for fences) and BS EN ISO 1461 (Hot-dip galvanized coatings on fabricated iron and steel articles) are also commonly met.

- Security Rating Standards: While not a single global standard, 358 Security Fence typically meets or exceeds the requirements for medium to high-level security classifications in national security frameworks (e.g., UK Centre for the Protection of National Infrastructure - CPNI guidelines for perimeter security).

Reputable manufacturers often partner with accredited testing laboratories to conduct independent verification of their products' anti-cut and anti-climb properties, ensuring real-world performance validation. Years of service and a portfolio of partner clients in critical infrastructure sectors further establish authoritativeness.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ)

Q: What makes the 358 Security Fence anti-climb?

A: Its extremely tight mesh aperture (76.2mm x 12.7mm) prevents human fingers and toes from finding purchase, making it almost impossible to climb without specialized tools.

Q: Can the 358 fence be cut?

A: While no fence is 100% uncuttable, the high-tensile 4.0mm wire and dense mesh make it incredibly difficult to cut with standard bolt cutters. It requires multiple, time-consuming cuts, significantly increasing the time taken for a breach attempt.

Q: How long does a 358 Security Fence typically last?

A: With proper hot-dip galvanization and a quality powder or PVC coating, the fence has an expected service life of 20-25 years or more, even in challenging environmental conditions.

Q: Is installation difficult?

A: Installation requires professional expertise due to the heavy-duty nature of the panels and posts, as well as the need for precise alignment to maintain security integrity. However, the modular panel design facilitates efficient installation by experienced teams.

Lead Time & Fulfillment

Standard orders for 358 Security Fence panels and posts typically have a lead time of 3-5 weeks from order confirmation, subject to current production schedules and material availability. Customized solutions or very large-scale projects may require extended lead times, which will be accurately communicated during the quotation phase. Expedited manufacturing and shipping options are available upon request for urgent projects.

Warranty Commitments

Our 358 Security Fence products are backed by a comprehensive warranty program. Standard warranties typically include a 10-year guarantee against manufacturing defects and a 15-20 year anti-corrosion warranty for hot-dip galvanized and powder-coated finishes, depending on the specific coating system and environmental conditions. Full warranty details are provided with each quotation and contract.

Customer Support and After-Sales Service

We are committed to providing exceptional customer support, from initial consultation and design assistance to post-installation service. Our dedicated technical support team offers:

- Technical guidance and product specifications.

- Installation advice and best practices.

- Troubleshooting assistance for any product-related inquiries.

- Spare parts availability and replacement assistance.

Our goal is to ensure long-term satisfaction and the continued optimal performance of your security infrastructure.

Conclusion

The 358 Security Fence represents the pinnacle of modern perimeter security, offering an unmatched combination of anti-climb, anti-cut, and anti-visibility attributes. Its robust construction, meticulously engineered manufacturing process, and diverse customization options make it the ideal choice for safeguarding critical assets across a multitude of high-security applications. Investing in this advanced fencing solution provides not just a physical barrier, but a comprehensive security strategy designed for longevity, resilience, and peace of mind.

References

- ASTM International. F2781/F2781M-20, Standard Practice for Testing Forced Entry Resistance of Welded Wire Mesh Fence Fabric. ASTM International, West Conshohocken, PA, 2020.

- ISO 9001:2015, Quality management systems – Requirements. International Organization for Standardization, Geneva, Switzerland, 2015.

- ISO 1461:2022, Hot-dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods. International Organization for Standardization, Geneva, Switzerland, 2022.

- Centre for the Protection of National Infrastructure (CPNI), Physical Security Manual – Perimeter Security. UK Government, 2023.

- MarketsandMarkets. "Security Fencing Market - Global Forecast to 2027." Industry Research Report, 2022.

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.