perforated metal screen,perforated metal sheet,perforated metal screen panels,perforated metal panels architectural,perforated metal panels,perforated metal panel railing,perforated metal panel ceiling,perforated metal mesh sheet,perforated mesh sheet is a key solution in the manufacturing industry, specifically within Fabricated metal products and Metal mesh manufacturing. This article explores how AnPing Zhongtai Expanded Metal Mesh Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- perforated metal screen,perforated metal sheet,perforated metal screen panels,perforated metal panels architectural,perforated metal panels,perforated metal panel railing,perforated metal panel ceiling,perforated metal mesh sheet,perforated mesh sheet Overview

- Benefits & Use Cases of perforated metal screen,perforated metal sheet,perforated metal screen panels,perforated metal panels architectural,perforated metal panels,perforated metal panel railing,perforated metal panel ceiling,perforated metal mesh sheet,perforated mesh sheet in Metal mesh manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on perforated metal screen,perforated metal sheet,perforated metal screen panels,perforated metal panels architectural,perforated metal panels,perforated metal panel railing,perforated metal panel ceiling,perforated metal mesh sheet,perforated mesh sheet from AnPing Zhongtai Expanded Metal Mesh Co., Ltd

perforated metal screen,perforated metal sheet,perforated metal screen panels,perforated metal panels architectural,perforated metal panels,perforated metal panel railing,perforated metal panel ceiling,perforated metal mesh sheet,perforated mesh sheet Overview

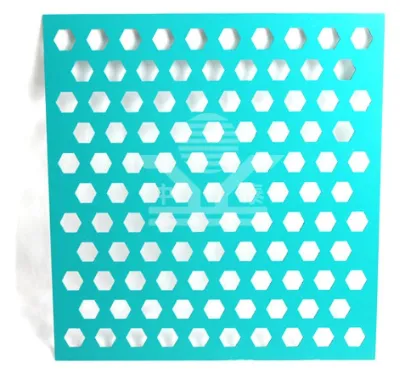

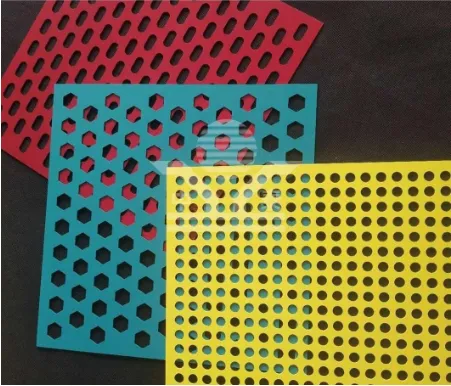

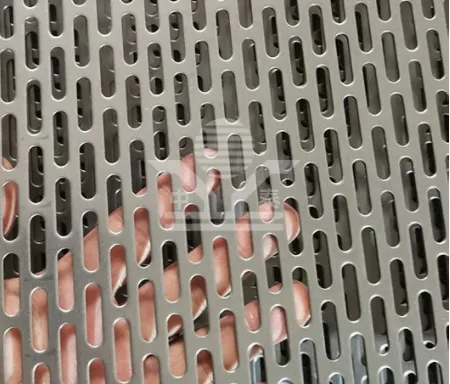

Perforated metal solutions combine structural integrity with precise open area to deliver airflow, light transmission, acoustics, and filtration in one engineered surface. A typical perforated metal sheet is produced by coil-fed CNC punching or turret presses, creating round, slotted, square, or decorative holes across carbon steel, galvanized, aluminum, or stainless grades such as 304 and 316. Common specifications include thicknesses from 0.5–5.0 mm, hole diameters from 1–50 mm, open area from 10–60%+, and standard sizes up to 1500 × 3000 mm or custom coil lengths. Finishes range from mill and brushed to powder-coated or anodized for architectural performance.

For B2B buyers, the product family spans perforated metal screen and perforated mesh sheet for process equipment and guarding, as well as perforated metal panels architectural for façades, sunshades, and acoustic claddings. AnPing Zhongtai Expanded Metal Mesh Co., Ltd engineers tight tolerances, consistent flatness, and clean edges to streamline downstream forming, welding, and installation. Whether you need a high-flow perforated metal screen panels package for HVAC or a premium aesthetic perforated metal panel ceiling system, Zhongtai’s custom patterning, tooling library, and short lead times support demanding production schedules.

Benefits & Use Cases of perforated metal screen,perforated metal sheet,perforated metal screen panels,perforated metal panels architectural,perforated metal panels,perforated metal panel railing,perforated metal panel ceiling,perforated metal mesh sheet,perforated mesh sheet in Metal mesh manufacturing

In metal mesh manufacturing, precision punching and repeatable patterning are critical to deliver predictable open area, rigidity, and surface aesthetics. Perforated metal screen components excel in equipment guarding, sieving, and acoustic enclosures where airflow, visibility, and safety ratings must align. Perforated metal panels architectural enable façade shading, daylighting, and branding through custom motifs, while perforated metal panel railing solutions provide code-compliant visibility and anti-climb performance for industrial platforms and public infrastructure. In interiors, perforated metal panel ceiling systems combine acoustic absorption (with backing) and service access.

AnPing Zhongtai Expanded Metal Mesh Co., Ltd differentiates with application-specific design support: selecting hole types, pitch, and stagger to balance strength-to-weight ratio, stiffness, and open area. For filtration and screening, a perforated metal mesh sheet or perforated mesh sheet can be matched to target particle size and pressure drop. For exterior durability, stainless perforated metal panels and marine-grade finishes maximize lifecycle. Competitive advantages include optimized nest layouts to minimize scrap, burr-free edges for safer handling, and compatibility with forming, rolling, and frame integration to reduce total assembly time.

Cost, Maintenance & User Experience

Total cost of ownership improves when materials and patterns are engineered for the environment and duty cycle. Stainless perforated metal sheet reduces repainting and corrosion-related downtime, while galvanized or coated options offer value in low-to-moderate exposure. By selecting the right open area and thickness, buyers avoid over-specifying material and cut weight, enabling faster installation and lower freight costs. Many customers in the fabricated metal products sector report reduced rework thanks to consistent flatness and tight hole tolerances that keep downstream processes predictable.

Maintenance is straightforward: periodic rinsing or wipe-downs typically restore appearance and airflow. In architectural systems, perforated metal panels resist UV and weathering; in industrial screening, their robust impact resistance and formability allow for practical refurbishment or section replacement. AnPing Zhongtai Expanded Metal Mesh Co., Ltd supports ROI with reliable lead times, packaging that protects edges and finishes, and documentation to simplify procurement. The result is a long-lived perforated metal screen panels solution with stable performance and fewer plant interruptions.

Sustainability & Market Trends in manufacturing

Perforated metals align naturally with sustainability: they are durable, readily recyclable, and enable efficiency benefits such as reduced lighting loads through daylighting, improved ventilation, and targeted acoustics with less bulk material. As green building frameworks emphasize lifecycle performance and material circularity, perforated metal panels architectural and perforated metal panel ceiling solutions help designers meet functional and environmental objectives simultaneously.

Market trends favor mass customization, digital patterning, and integrated systems—combining perforated metal panels with frames, stiffeners, and mounting hardware to shorten site labor. There is also rising demand for corrosion-resistant perforated metal screen in coastal and industrial atmospheres, and for safety-compliant perforated metal panel railing in public spaces. AnPing Zhongtai Expanded Metal Mesh Co., Ltd invests in advanced punching technology, quality control, and finish options to reduce waste, extend service life, and support evolving regulatory expectations, positioning your projects for both compliance and competitiveness.

Conclusion on perforated metal screen,perforated metal sheet,perforated metal screen panels,perforated metal panels architectural,perforated metal panels,perforated metal panel railing,perforated metal panel ceiling,perforated metal mesh sheet,perforated mesh sheet from AnPing Zhongtai Expanded Metal Mesh Co., Ltd

From process screening to signature façades, perforated metal solutions deliver strength, airflow, acoustics, and design flexibility in a single, efficient component. AnPing Zhongtai Expanded Metal Mesh Co., Ltd provides dependable quality, pattern expertise, and finishing choices that help B2B decision-makers achieve performance targets with predictable costs and timelines.

Contact us: email: hht15531800319@outlook.com

Visit our website: https://www.ztwiremesh.com

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.