Frame fence is a key solution in the construction industry, specifically within Building Materials and Components and Fencing fence. This article explores how AnPing Zhongtai Expanded Metal Mesh Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Frame fence Overview

- Benefits & Use Cases of Frame fence in Fencing fence

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in construction

- Conclusion on Frame fence from AnPing Zhongtai Expanded Metal Mesh Co., Ltd

Frame fence Overview

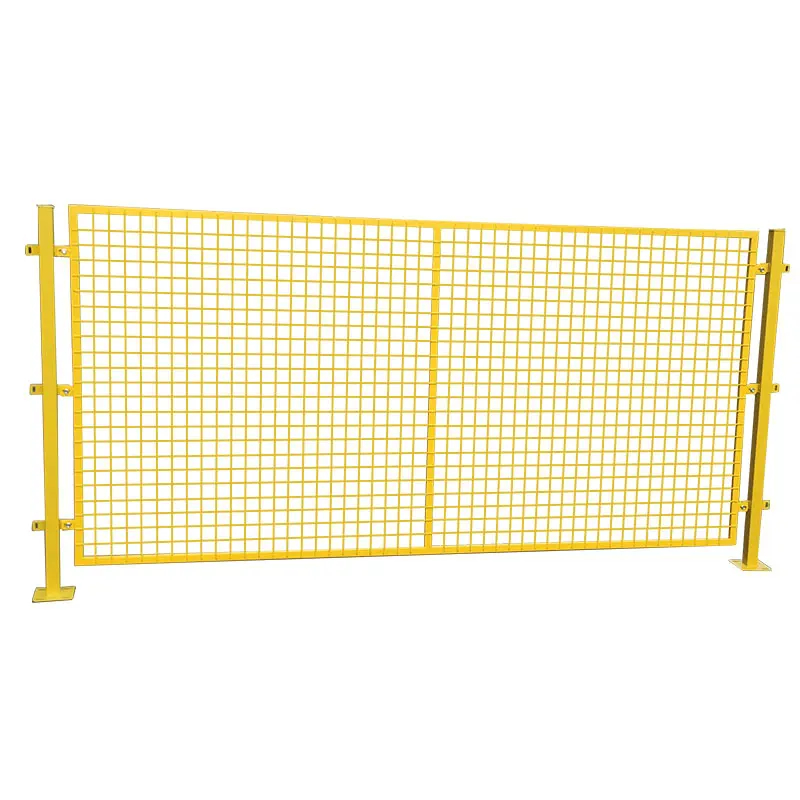

Frame fence refers to rigid, welded wire mesh panels integrated into rectangular tubular frames and mounted to posts using clamps or bolts. In construction and the wider Building Materials and Components sector, this design delivers a strong, modular perimeter solution that resists deformation, accelerates installation, and maintains a consistent visual line. Typical specifications include wire diameters of 3.0–6.0 mm, mesh apertures such as 50×150 mm or 60×120 mm, framed with 20×30, 30×30, or 40×40 mm tubes, and post options like 48–60 mm round or 60×60 mm square. Surfaces are commonly hot-dip galvanized and polyester powder coated to extend service life and color-match site branding.

AnPing Zhongtai Expanded Metal Mesh Co., Ltd manufactures frame fence systems with precision welding, tight flatness tolerances, and robust coatings engineered for outdoor performance. Panels, frames, and posts are designed to integrate with standardized brackets, base plates (for temporary or paved installs), and anti-theft fasteners. For buyers who manage multiple sites across varying terrains, Zhongtai’s modular approach offers flexible panel widths (often 2.0–3.0 m) and heights (1.2–2.4 m+), along with custom RAL finishes to meet project aesthetics and visibility requirements.

Benefits & Use Cases of Frame fence in Fencing fence

Across transportation corridors, energy substations, logistics parks, industrial plants, schools, and sports facilities, frame fence systems provide dependable demarcation and security. Their rigid frames improve panel stability in high-traffic areas and wind-prone zones, while the welded mesh maintains visibility for surveillance and safety compliance. For temporary events or construction perimeters, base plates and quick clamps enable rapid setup and removal; for permanent perimeters, embedded or flange-mounted posts provide long-term anchoring.

Key advantages include modular installation that reduces on-site fabrication, durable anti-corrosion treatments for multi-year performance, and easy integration with swing or sliding gates. Compared with chain-link alternatives, a frame fence typically offers a flatter, more uniform presentation, reduced sag over time, and straightforward panel replacement if damaged. AnPing Zhongtai Expanded Metal Mesh Co., Ltd brings deep expertise in mesh forming, framing, coating, and packaging for export. The company supports custom specifications—wire gauge, aperture, frame tube size, and finish thickness—so B2B decision makers can align performance, budget, and brand identity. The result is a balance of strength, aesthetics, and speed of deployment that fits facility upgrades and new builds alike.

Cost, Maintenance & User Experience

Total cost of ownership for a frame fence centers on material and coating quality, installation efficiency, and maintenance intervals. With prefabricated framed panels, crews spend less time cutting, aligning, and tensioning on site, which reduces labor costs and shortens shutdowns. High-quality galvanizing and UV-stable powder coating help minimize rust, repainting, and component replacement, supporting a favorable ROI over a 10-year horizon and beyond—especially in industrial or coastal environments where corrosion is a priority.

End users in the Building Materials and Components sector often highlight predictable performance: panels stay true and square, clamps keep connections tight, and damaged panels can be swapped without disturbing adjacent runs. Routine care is limited to periodic inspection of fixings and occasional washing to remove dust or salts. AnPing Zhongtai Expanded Metal Mesh Co., Ltd enhances user experience through consistent panel dimensions, clear labeling, and protective packaging that reduces transit damage. For multi-site rollouts, standardized components and replenishable spares simplify procurement and inventory management, keeping fences operational with minimal downtime and maintenance spend.

Sustainability & Market Trends in construction

Sustainability considerations increasingly shape perimeter solutions. Steel-based frame fence systems are recyclable at end of life, while durable hot-dip galvanizing and low-VOC powder coatings extend service life and reduce repaint cycles—lowering embodied environmental impact over time. Specifiers are moving toward modular, prefabricated components to limit on-site waste and reduce installation-related emissions. Growing adoption of color-stable coatings also helps maintain appearance without frequent touch-ups.

Market demand is driven by urbanization, infrastructure expansion, and stricter perimeter safety expectations across utilities, logistics, and public venues. Decision makers want solutions that combine security, transparency, and brand-aligned aesthetics with rapid deployment. AnPing Zhongtai Expanded Metal Mesh Co., Ltd responds with process improvements aimed at energy-efficient curing, scrap steel recycling, and coating recovery practices, while providing technical data to support compliance and environmental goals. The company can collaborate on CAD/BIM submittals, helping design teams model accurate take-offs and integrate gates, turns, and gradients—accelerating approvals and optimizing material usage.

Conclusion on Frame fence from AnPing Zhongtai Expanded Metal Mesh Co., Ltd

For construction professionals, a frame fence delivers a durable, modular, and visually consistent perimeter that installs quickly and performs reliably over years of service. AnPing Zhongtai Expanded Metal Mesh Co., Ltd combines precise fabrication, protective coatings, and project-ready packaging to meet the needs of infrastructure, industrial, and commercial sites worldwide. Partner with a manufacturer that understands B2B timelines, quality standards, and lifecycle value.

Contact us: email: hht15531800319@outlook.com

Visit our website: https://www.ztwiremesh.com

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.