Introduction to Advanced Flow Forge Grating Solutions

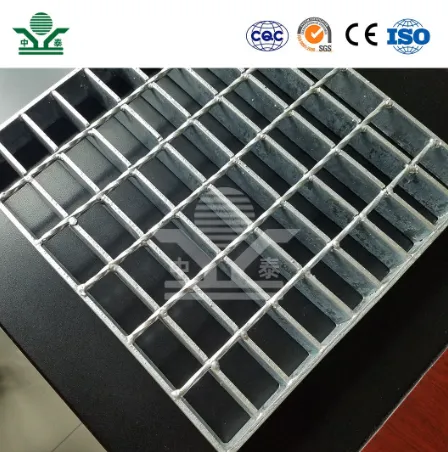

In the realm of industrial infrastructure, the selection of robust and reliable flooring and surface materials is paramount. Among the diverse options available, flow forge grating stands out as a superior engineered solution, critical for ensuring safety, durability, and operational efficiency across a multitude of B2B applications. This high-performance grating is distinguished by its unique manufacturing process, offering unparalleled strength, corrosion resistance, and load-bearing capabilities. Engineered for environments demanding maximum structural integrity and longevity, it serves as an indispensable component in everything from heavy industrial platforms to intricate drainage systems.

This comprehensive overview delves into the intricate details of its production, technical advantages, diverse applications, and critical factors for procurement, providing B2B decision-makers with the insights needed to implement optimal grating solutions for their projects.

Current Industry Trends and Market Drivers for Metal Grating

The market for metal grating, particularly in the B2B sector, is experiencing robust growth driven by escalating global investments in infrastructure, industrial expansion, and increasingly stringent safety regulations. Key trends highlight a rising demand for specialized solutions such as forge welded grating and high-performance grating systems capable of withstanding extreme conditions. The push for sustainable and long-lasting materials also fuels the adoption of solutions like galvanised metal grating, known for its extended service life and reduced maintenance requirements.

Technological advancements in manufacturing processes, including automation and precision engineering, are leading to higher quality and more cost-effective grating products. Furthermore, there's a significant focus on ergonomic design and anti-slip properties to enhance worker safety, making products like galvanized steel walkways and heavy duty steel bar grating essential components in modern industrial facilities. The increasing complexity of industrial environments, from offshore platforms to wastewater treatment plants, necessitates customized grating solutions that can adapt to specific load requirements, chemical exposures, and environmental factors, driving innovation in material composites and surface treatments. This trend underscores the importance of resilient, adaptable, and specification-compliant grating for future industrial development.

The Advanced Manufacturing Process of Flow Forge Grating

The production of flow forge grating involves a sophisticated sequence of engineering and metallurgical processes designed to create a product of superior strength and integrity. This method distinguishes itself from conventional grating manufacturing by creating a robust, monolithic structure that is highly resistant to impact, fatigue, and environmental degradation.

Key Stages of the Process:

- Material Selection and Preparation: High-quality raw materials, typically mild steel (e.g., Q235, Q345) or stainless steel (e.g., SS304, SS316), are chosen based on the intended application's load-bearing and corrosion resistance requirements. These materials undergo strict quality inspection to ensure chemical composition and mechanical properties meet international standards (e.g., ASTM A36, JIS G3101).

- Slitting and Cutting: Bearing bars, which form the primary load-carrying elements, are precisely cut from steel sheets or coils to specified dimensions. This ensures uniformity and adherence to design parameters.

- Notching and Punching (Optional): For specific designs requiring enhanced grip or drainage, bearing bars may be notched or punched.

- Cross Bar Preparation: Round or square twisted cross bars are prepared, often by cold rolling or hot forging, to create their characteristic shape.

- Forging and Welding Integration (Key Process): This is the defining stage for forge welded grating. Bearing bars are precisely spaced and aligned, and the pre-formed cross bars are inserted into pre-cut slots in the bearing bars. Under immense heat and pressure, the cross bars are hydraulically forced into the bearing bars. This forging action, combined with simultaneous resistance welding, permanently fuses the two components together. The process creates a highly robust, integral structure where the cross bars are deeply embedded into the bearing bars, eliminating the need for fillet welds and enhancing load distribution.

- Edge Banding (Optional): For enhanced aesthetics, increased stability, or specific installation requirements, flat bars may be welded to the edges of the grating panel.

- Surface Treatment: The finished grating panels are often hot-dip galvanized according to standards like ASTM A123/A123M or ISO 1461. This process provides an exceptionally durable zinc coating that offers superior corrosion resistance, crucial for products like galvanised metal grating used in harsh environments such as petrochemical plants and marine applications. Other treatments may include painting or powder coating for specific aesthetic or protective requirements.

- Quality Control and Testing: Each panel undergoes rigorous testing, including visual inspection, dimensional checks, load-bearing tests (to standards like ANSI/NAAMM MBG 531), and adhesion tests for galvanized coatings. Adherence to ISO 9001 quality management systems is standard across reputable manufacturers.

This meticulous process ensures that the final flow forge grating exhibits exceptional strength, longevity, and structural integrity, contributing to its suitability for demanding applications across target industries such as petrochemical, metallurgy, power generation, and water supply & drainage. The monolithic structure inherently offers superior energy absorption characteristics and enhanced resistance to fatigue compared to alternative grating types, promoting extended service life often exceeding 20-30 years in typical industrial settings when properly maintained.

Technical Specifications and Parameters of Flow Forge Grating

Understanding the precise technical specifications of flow forge grating is critical for engineers and procurement specialists to ensure optimal performance and safety. These parameters dictate the grating's load-bearing capacity, span capabilities, and suitability for various environmental conditions. Manufacturers adhere to international standards to provide consistent quality and verifiable performance data.

Standard Product Specification Table:

| Parameter | Description | Typical Range/Value | Relevant Standard |

|---|---|---|---|

| Material Grade | Standard materials for industrial applications | Mild Steel (Q235, Q345, A36), Stainless Steel (SS304, SS316) | ASTM A36, JIS G3101, EN 10025 |

| Bearing Bar Size | Height x Thickness of load-carrying bars | 25x3mm to 100x8mm (common for heavy duty mild steel grating) | ANSI/NAAMM MBG 531 |

| Bearing Bar Pitch | Center-to-center spacing of bearing bars | 30mm, 40mm, 60mm (for grating steel floor) | ISO 9440, AS 1657 |

| Cross Bar Pitch | Center-to-center spacing of cross bars | 50mm, 100mm, 75mm | ISO 9440, AS 1657 |

| Surface Treatment | Corrosion protection | Hot-Dip Galvanized, Painted, Self-Color | ASTM A123/A123M, ISO 1461 |

| Panel Size | Maximum standard panel dimensions | Up to 6000mm (length) x 1000mm (width) | Manufacturer Specific |

| Load Capacity | Distributed and concentrated load performance | Varies significantly by bar size and pitch (e.g., up to 200 kN/m² for heavy duty steel bar grating) | ANSI/NAAMM MBG 531, BS 4592 |

These specifications enable precise engineering for applications demanding high structural integrity, such as industrial flooring, trench covers, and maintenance platforms. For instance, a grated metal floor with 30x5mm bearing bars at 30mm pitch, hot-dip galvanized, offers exceptional load capacity and corrosion resistance for demanding industrial environments.

Unparalleled Technical Advantages of Flow Forge Grating

The unique manufacturing process of flow forge grating imbues it with a suite of technical advantages that make it a preferred choice for demanding industrial and commercial applications. These benefits translate directly into enhanced operational safety, extended service life, and optimized total cost of ownership.

- Superior Strength-to-Weight Ratio: The forge welding process creates an integral, robust structure that maximizes load-bearing capacity while maintaining a relatively light weight. This makes it ideal for platforms and walkways where structural integrity is critical without imposing excessive loads on supporting structures.

- Exceptional Load Distribution: The deeply embedded cross bars distribute loads efficiently across the bearing bars, preventing localized stress concentrations and enhancing the overall structural stability, crucial for heavy duty steel bar grating.

- Corrosion Resistance: When hot-dip galvanized (galvanized steel walkways), flow forge grating offers outstanding resistance to rust and corrosion, even in aggressive chemical environments or outdoor conditions. The sacrificial zinc coating protects the steel, ensuring a long service life and minimal maintenance.

- Anti-Slip Properties: The twisted cross bars and optional serrated bearing bars provide excellent anti-slip characteristics, significantly reducing the risk of slips and falls in wet or oily industrial settings, improving worker safety on any grating steel floor.

- Optimized Ventilation and Light Penetration: The open mesh design allows for effective air circulation, which is vital in areas with heat or fumes. It also permits light to penetrate to lower levels, reducing the need for artificial lighting and contributing to energy savings in large facilities.

- Ease of Fabrication and Installation: Despite its strength, flow forge grating can be readily cut, fabricated, and installed to suit complex layouts, including cut-outs for pipes and machinery. Its modular nature allows for quick and efficient assembly on-site.

- Long Service Life: Due to its robust construction and effective corrosion protection, flow forge grating boasts an exceptionally long service life, often exceeding several decades, minimizing replacement costs and downtime.

These advantages collectively position flow forge grating as a premium solution for B2B clients seeking reliable, high-performance grating systems that contribute to operational safety, efficiency, and long-term value.

Diverse Application Scenarios for Flow Forge Grating

The versatility and inherent strength of flow forge grating make it suitable for an expansive array of industrial, commercial, and public infrastructure applications. Its adaptability to various load conditions and environmental exposures ensures optimal performance across diverse sectors.

Key Application Sectors:

- Petrochemical and Chemical Plants: Used extensively for platforms, stair treads, and maintenance walkways due to its corrosion resistance (especially galvanized steel walkways) and ability to withstand harsh chemical exposures and high temperatures.

- Power Generation Facilities: Essential for boiler platforms, turbine decks, and access ways in power plants (coal, gas, nuclear), where high load capacity and anti-slip properties are critical for safety.

- Water Treatment and Wastewater Facilities: Ideal for trench covers (like the Traffic Trench Drain Grate China Manufacturing Metal Security Window Grates), sumps, and filter beds, offering excellent drainage and corrosion resistance in constantly wet environments.

- Mining and Mineral Processing: Heavy duty mild steel grating and heavy duty steel bar grating are deployed in processing plants for conveyor walkways, screening areas, and crusher platforms, where extreme abrasion and heavy loads are common.

- Marine and Offshore Structures: Utilized for offshore oil rigs, ship decks, and port facilities due to its superior strength and corrosion resistance in saline and humid atmospheres.

- Transportation Infrastructure: Applied as bridge walkways, pedestrian overpasses, and specifically as grated metal floor for traffic trenches and drainage systems, where it must support vehicular loads and provide efficient water runoff.

- Food and Beverage Industry: Stainless steel flow forge grating provides hygienic and durable flooring solutions, able to withstand frequent wash-downs and chemical sanitization processes.

- Architectural Applications: Increasingly used for aesthetic purposes in facades, sunscreens, and decorative elements due to its clean lines and robust appearance.

The ability of flow forge grating to combine exceptional strength, safety features, and adaptability makes it an indispensable material for a wide range of critical infrastructure projects, underpinning operational continuity and worker protection.

Tailored Excellence: Customized Solutions for Flow Forge Grating

While standard flow forge grating offers broad applicability, many industrial projects necessitate bespoke solutions to perfectly align with unique structural, operational, and safety requirements. Leading manufacturers of forge welded grating excel in providing highly customized grating products, ensuring optimal fit and performance for even the most complex applications.

Customization Capabilities Include:

- Specific Dimensions and Layouts: Grating panels can be manufactured to precise lengths and widths, including intricate cuts, angles, and shapes to accommodate columns, pipes, and machinery. This minimizes on-site fabrication and waste.

- Varied Bearing Bar and Cross Bar Spacing: Adjusting the pitch of bearing bars (e.g., for different load classes of heavy duty steel bar grating) and cross bars allows for precise control over load capacity, open area percentage, and anti-slip characteristics.

- Material Alternatives: Beyond standard mild steel and stainless steel, specialized alloys can be utilized for extreme environments requiring enhanced chemical resistance or high-temperature stability.

- Surface Finishes: Custom finishes include various galvanizing thicknesses, specialized paint systems (e.g., epoxy, polyurethane) for specific chemical resistance or aesthetic requirements, and anti-slip treatments such as serrated bearing bars for superior traction in wet or oily conditions.

- Integrated Features: Custom designs can incorporate toe plates, kick plates, special banding, lifting eyes, or access panel cut-outs directly into the grating panels during fabrication, simplifying installation and enhancing functionality.

- Load-Specific Designs: Engineering teams can design grating galvanized steel solutions for very specific point loads, distributed loads, or dynamic loads, often performing finite element analysis (FEA) to validate structural integrity.

By offering comprehensive customization, suppliers ensure that clients receive a grating solution that is not merely functional but perfectly integrated into their project's unique demands, optimizing both performance and cost-effectiveness. This approach enhances the overall longevity and safety of industrial installations, particularly for bespoke applications like specialized trench drain covers or intricate industrial platforms.

Vendor Comparison: Selecting the Right Partner for Flow Forge Grating

Choosing the right supplier for flow forge grating is a critical decision that impacts project timelines, product quality, and long-term operational costs. A thorough evaluation of potential vendors based on several key differentiators is essential for B2B procurement professionals.

Key Differentiators in Vendor Selection:

| Criteria | High-Performing Vendor Attributes | Considerations for Evaluation |

|---|---|---|

| Manufacturing Capability & Technology | Advanced forging machinery, robotic welding, high-capacity galvanizing lines. | Ability to handle large-scale orders, precision manufacturing, capacity for heavy duty steel bar grating. |

| Quality Certifications & Standards | ISO 9001:2015, CE marking, adherence to ASTM, ANSI, BS, AS standards. | Proof of compliance, independent audit reports, material test certificates. |

| Customization & Engineering Support | Dedicated engineering team, CAD/CAM capabilities, FEA services for bespoke designs. | Ability to provide detailed shop drawings, design for specialized grated metal floor. |

| Lead Times & Fulfillment | Consistent on-time delivery, efficient logistics, transparent scheduling. | Track record, communication protocols for delays, export capabilities for grating galvanized steel. |

| Pricing & Value Proposition | Competitive pricing, transparent cost breakdown, emphasis on long-term value. | Avoid overly cheap options (risk of quality compromise), assess total cost of ownership. |

| After-Sales Support & Warranty | Comprehensive warranty, responsive customer service, technical assistance. | Clarity on warranty terms, ease of contacting support, problem resolution history. |

By rigorously assessing these factors, B2B purchasers can identify a reliable partner capable of delivering high-quality flow forge grating solutions that meet project specifications and budget constraints while ensuring long-term performance and compliance.

Real-World Impact: Application Case Studies for Flow Forge Grating

The practical deployment of flow forge grating across various industries consistently demonstrates its value in improving safety, durability, and operational efficiency. These case studies highlight the tangible benefits of choosing this engineered solution.

Case Study 1: Petrochemical Processing Plant - Elevated Walkways

A major petrochemical complex required an extensive network of elevated walkways and platforms for maintenance and inspection access. The environment presented significant challenges, including exposure to corrosive chemicals, high humidity, and heavy foot traffic. The solution involved installing 15,000 square meters of galvanized steel walkways made from flow forge grating (bearing bar 30x5mm, 30mm pitch). The hot-dip galvanization provided superior corrosion resistance, while the forge-welded construction ensured exceptional load-bearing capacity and anti-slip properties, even when exposed to oil spills. The project achieved a significant reduction in maintenance costs over a 10-year period compared to previously used materials, with zero reported slip-and-fall incidents related to grating failure.

Case Study 2: Municipal Wastewater Treatment Facility - Trench Drain Covers

A new wastewater treatment plant in a metropolitan area needed durable and secure trench drain covers capable of withstanding constant moisture, corrosive gases, and occasional vehicle traffic. The client selected Traffic Trench Drain Grate China Manufacturing Metal Security Window Grates, a specific configuration of grating galvanized steel. Custom-sized panels of 40x5mm bearing bars with 40mm pitch were specified to accommodate varying trench widths and ensure adequate drainage while preventing debris accumulation. The robust construction and heavy-duty galvanization ensured a projected service life of 25 years, significantly exceeding the client's initial requirements and providing a reliable grated metal floor solution for critical drainage areas.

Case Study 3: Heavy Mining Operation - Industrial Flooring

In a large open-pit mining facility, the flooring in crushing and processing areas was subject to extreme impact loads from falling rock, heavy machinery traffic, and abrasive ore dust. Conventional materials were failing prematurely. The engineering team opted for a bespoke heavy duty steel bar grating solution, utilizing 60x8mm bearing bars at a 30mm pitch, fabricated from high-strength mild steel and hot-dip galvanized. This specialized grating steel floor solution demonstrated superior resilience, reducing the frequency of repairs by 70% and enhancing worker safety due to its inherent strength and anti-slip surface. The improved durability translated into substantial operational savings and reduced downtime for the mining company.

Frequently Asked Questions (FAQ) about Flow Forge Grating

Q1: How does flow forge grating differ from other welded gratings?

A1: Unlike standard resistance-welded grating where cross bars are typically surface welded, flow forge grating involves forging the cross bars into pre-cut slots in the bearing bars under immense heat and pressure, creating a stronger, monolithic structure with superior load distribution and fatigue resistance. This creates a true forge welded grating.

Q2: What is the typical service life of galvanized flow forge grating?

A2: With proper hot-dip galvanization to standards like ASTM A123/A123M, galvanised metal grating can offer a service life of 20-50 years, depending on the corrosivity of the environment and the thickness of the zinc coating. In mild industrial environments, it often exceeds 40 years.

Q3: Can flow forge grating be used for heavy vehicle traffic?

A3: Yes, specifically designed heavy duty steel bar grating configurations with thicker and taller bearing bars (e.g., 60x8mm or 100x8mm) and closer bar spacing are engineered for heavy vehicular traffic, such as in traffic trench drains or bridge decks. Load tables must be consulted to match the specific application requirements.

Q4: Is customization available for specific project requirements?

A4: Absolutely. Reputable manufacturers offer extensive customization options, including specific panel dimensions, bearing bar and cross bar pitches, material grades, cut-outs, special banding, and a variety of surface treatments to meet precise project specifications and load requirements for any grated metal floor.

Q5: What maintenance is required for grating galvanized steel?

A5: Hot-dip galvanized grating requires minimal maintenance. Routine cleaning to remove accumulated debris or sediment is generally sufficient. Occasional inspection for any signs of damage or significant wear, especially in high-traffic or corrosive areas, is recommended. Any damage to the zinc coating should be repaired with a zinc-rich paint.

Lead Time, Warranty, and After-Sales Support

Production and Lead Time:

Lead times for flow forge grating production typically range from 2 to 6 weeks, depending on the complexity of the order, material availability, quantity, and current manufacturing capacity. Standard sizes and specifications usually fall within the shorter end of this range, while highly customized or large-scale projects may require extended periods. We maintain transparent communication throughout the production cycle, providing regular updates on order status and expected delivery dates. Expedited options may be available upon request for urgent projects, subject to additional charges and capacity.

Warranty Commitments:

All our forge welded grating products are backed by a comprehensive warranty, typically covering manufacturing defects for a period of 5 to 10 years from the date of purchase, depending on the product type and application. Our warranty ensures that materials and workmanship meet or exceed industry standards. Specific terms and conditions, including limitations regarding improper installation, misuse, or unauthorized modifications, are detailed in our product documentation. We are committed to standing behind the quality and durability of our grating galvanized steel solutions.

Dedicated Customer Support:

Our commitment to our clients extends far beyond product delivery. We provide dedicated after-sales support to assist with any technical inquiries, installation guidance, or performance-related questions. Our team of experienced engineers and customer service representatives is available via phone, email, or online portal to provide timely and effective solutions. We also offer access to detailed product manuals, load tables, and maintenance guidelines to ensure the optimal long-term performance of your heavy duty mild steel grating and other solutions. Our goal is to ensure complete customer satisfaction and the sustained operational excellence of our grating systems.

Conclusion: The Enduring Value of Flow Forge Grating

As demonstrated throughout this comprehensive overview, flow forge grating represents an apex in industrial flooring and surface technology. Its advanced manufacturing process, yielding a monolithic and inherently strong structure, provides unmatched advantages in terms of load-bearing capacity, durability, and resistance to environmental degradation. From the most aggressive petrochemical environments to demanding heavy-duty traffic areas, the versatility and robust performance of these grating solutions ensure long-term safety, operational continuity, and minimized maintenance requirements.

For B2B decision-makers and engineers seeking reliable, high-performance, and cost-effective solutions for critical infrastructure, investing in flow forge grating from a certified and experienced manufacturer is a strategic choice that delivers enduring value and peace of mind.

References

- American National Standards Institute (ANSI) / National Association of Architectural Metal Manufacturers (NAAMM). (2009). Metal Bar Grating Manual (MBG 531-09).

- ASTM International. (2017). A123/A123M-17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

- International Organization for Standardization (ISO). (2019). ISO 9001:2015: Quality management systems – Requirements.

- International Organization for Standardization (ISO). (1999). ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles – Specifications and test methods.

- British Standards Institution (BSI). (2007). BS 4592-0:2007: Grating panels, walkway panels and stair treads. Definitions, general principles of design and areas of application.

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.