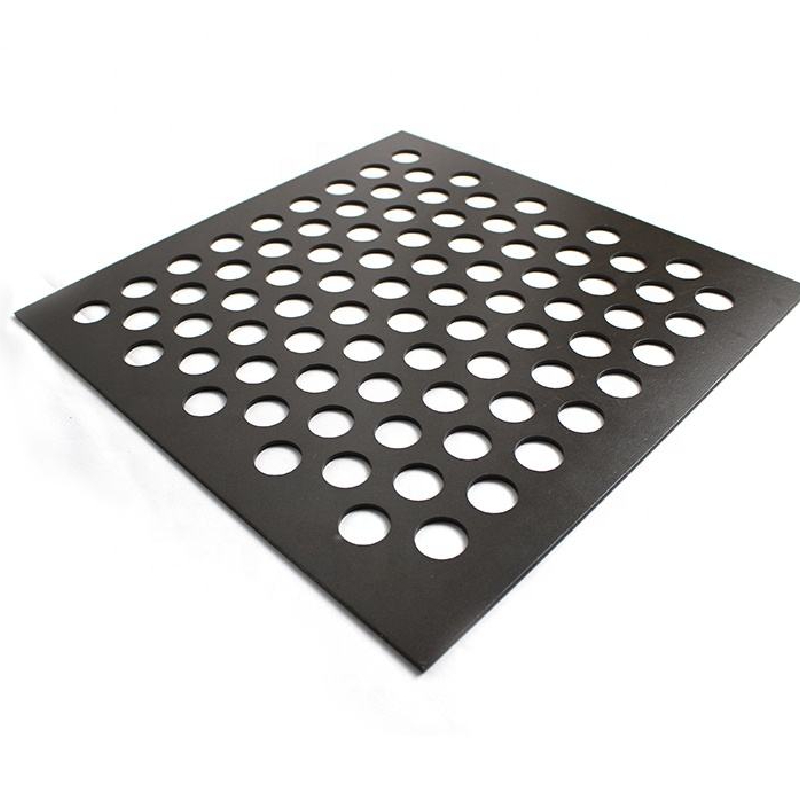

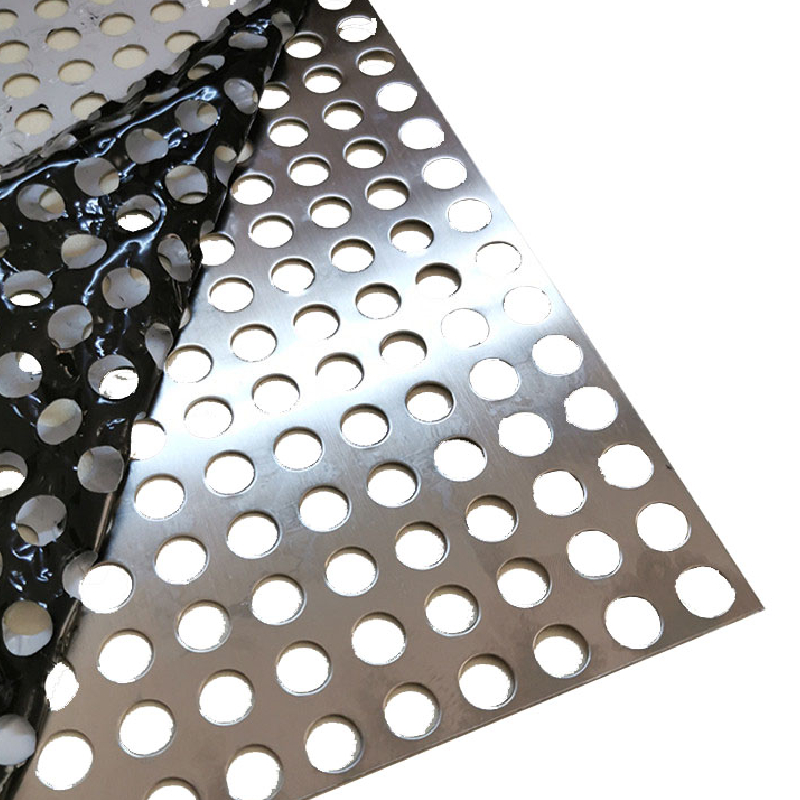

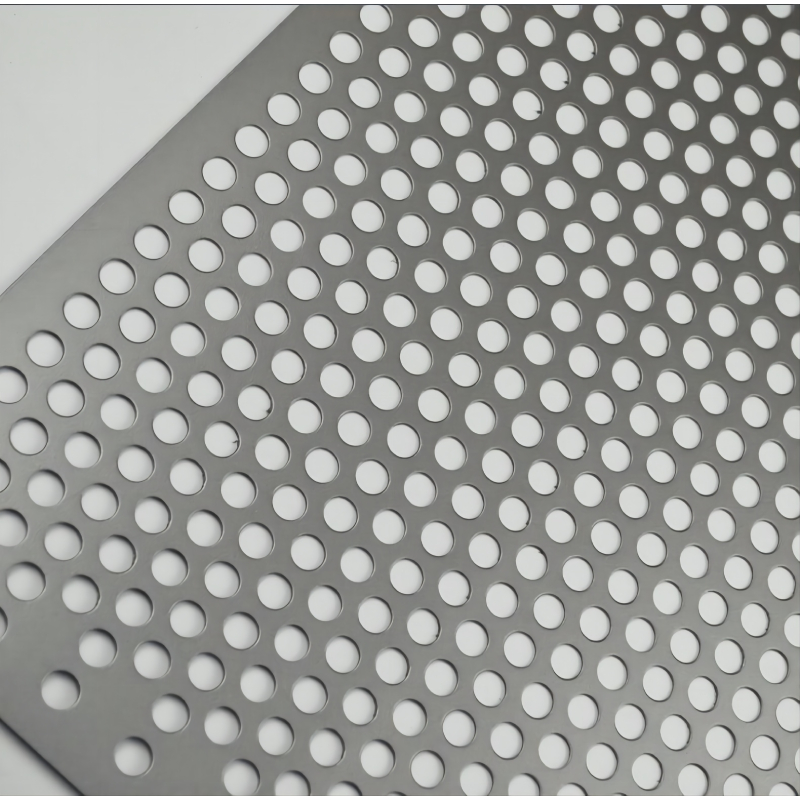

Unveiling the Versatility of Round Perforated Steel Sheet in Industrial Applications

The industrial landscape constantly demands materials that combine durability, functionality, and cost-effectiveness. Among these, round perforated steel sheet stands out as a highly adaptable and essential component. Characterized by its precisely punched circular holes, this material offers a unique blend of strength, permeability, and aesthetic appeal, making it indispensable across a spectrum of critical applications. From precise filtration and robust architectural cladding to efficient acoustic control and demanding safety barriers, its engineering capabilities are unparalleled. This comprehensive guide delves into the technical intricacies, manufacturing processes, diverse applications, and strategic advantages of this fundamental industrial product, providing key insights for B2B decision-makers and engineers.

The Detailed Manufacturing Process of Round Perforated Sheet

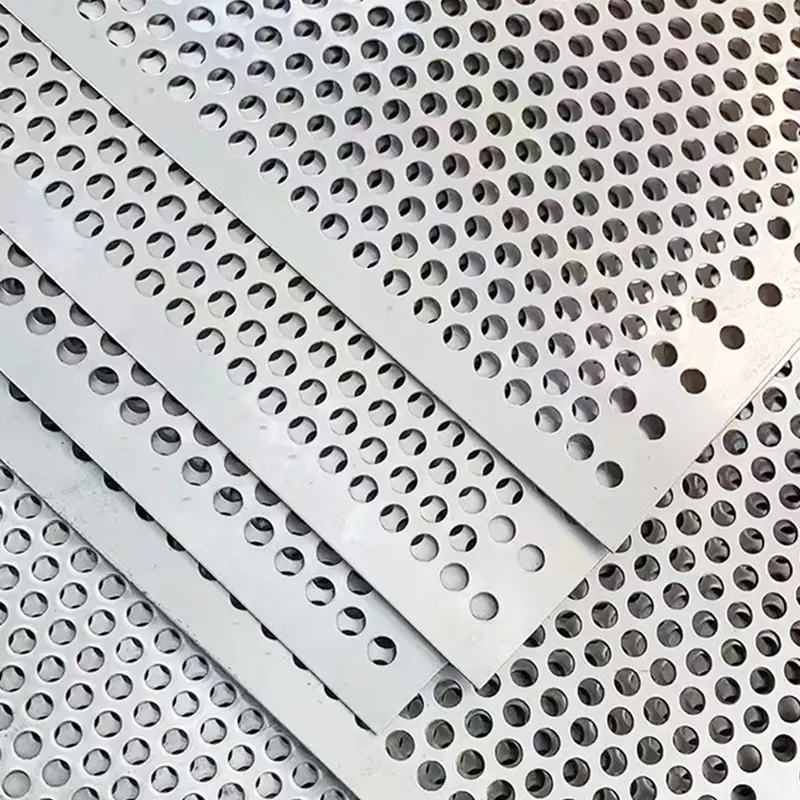

The production of round perforated steel sheet is a meticulous process, ensuring precise hole patterns and structural integrity. It typically involves several key stages, each optimized for quality and efficiency.

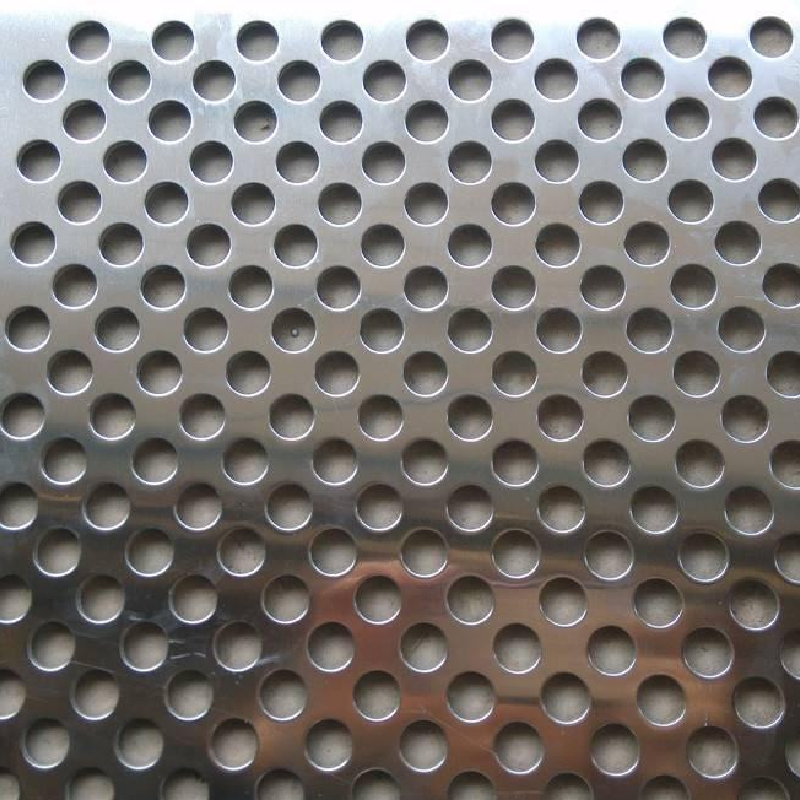

- Material Selection and Preparation: The process begins with selecting high-grade raw materials. Common choices include carbon steel, stainless steel (AISI 304, 316L), galvanized steel, aluminum, and various alloys. The choice of material is dictated by the end application's requirements for corrosion resistance, strength, and environmental exposure. Steel coils or sheets are inspected for surface imperfections and material consistency.

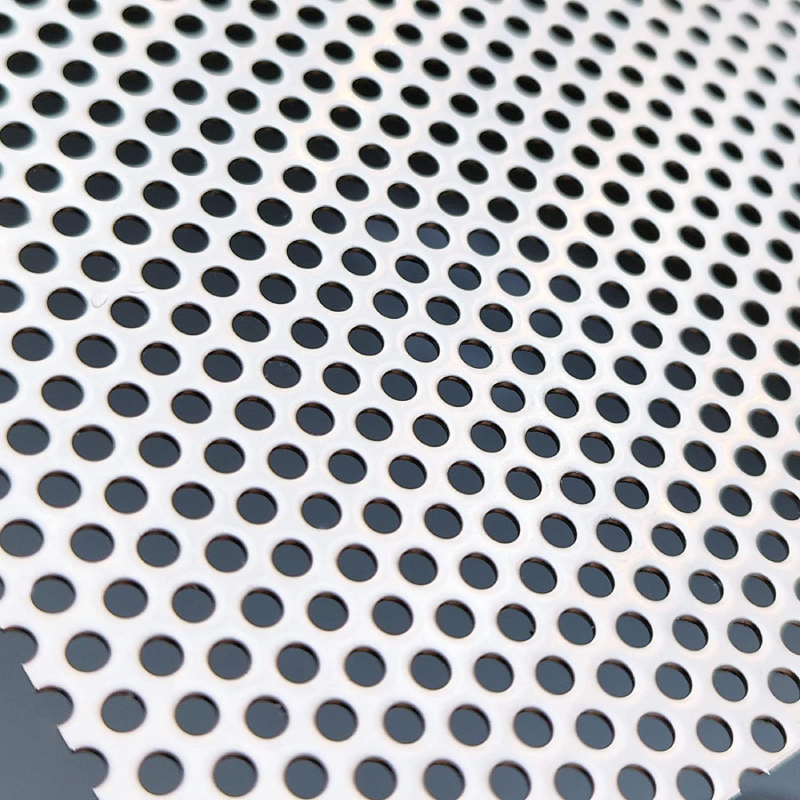

- Perforation (Punching/Stamping): The core of the manufacturing process involves perforating the chosen metal. This is typically done using high-speed CNC punching machines or mechanical presses equipped with specialized tooling. These machines accurately punch uniform round holes in various patterns (straight, staggered) and sizes. Advanced software controls ensure precise hole diameter, pitch (distance between hole centers), and margin specifications, minimizing material distortion.

- Leveling and Deburring: After perforation, the sheet may exhibit slight camber or bowing due to the punching forces. Leveling machines flatten the sheets to ensure a perfectly flat product. Deburring machines then remove any sharp edges or burrs around the perforations, ensuring a smooth, safe finish and preventing snags in subsequent applications.

-

Finishing Treatments: Depending on the application, the round perforated metal sheet undergoes various finishing processes. These can include:

- Galvanization (hot-dip or electro-galvanization) for enhanced corrosion resistance.

- Powder coating for aesthetic appeal and additional protection against wear and corrosion.

- Anodizing for aluminum sheets.

- Polishing or pickling for stainless steel to improve surface finish and passivity.

- Cutting and Fabrication: The finished round hole perforated sheet is then cut to specified dimensions, often involving shearing, laser cutting, or plasma cutting, based on client requirements. Further fabrication steps like bending, welding, or forming may also be performed.

- Quality Control and Testing: Throughout the process, strict quality control measures are implemented. This includes dimensional checks of hole size and pitch, material thickness verification, visual inspection for defects, and adherence to international standards such as ISO 9001, ASTM E2016 for perforated metal, and various ANSI standards for material properties. Service life is significantly enhanced through material selection, precise manufacturing, and appropriate surface treatments. For example, a 316L round hole perforated stainless steel sheet can offer decades of service in corrosive environments.

Target industries benefiting from these processes include petrochemical, metallurgy, water supply & drainage, food & beverage, pharmaceutical, and construction. In a typical petrochemical application, stainless steel round perforated steel sheet is used for catalyst support grids, demonstrating superior corrosion resistance and structural integrity under high temperatures and chemical exposure, leading to extended operational cycles and reduced maintenance.

Industry Trends and Market Dynamics

The market for round perforated metal is evolving, driven by several key trends:

- Sustainable Manufacturing: Increasing demand for environmentally friendly production processes and materials, including recycled content and energy-efficient manufacturing.

- Advanced Material Integration: Growth in the use of specialized alloys and composite materials that offer enhanced properties like extreme temperature resistance, lighter weight, and superior strength-to-weight ratios for niche applications.

- Customization and Personalization: A rising trend towards highly customized perforated patterns, hole sizes, and sheet dimensions to meet unique architectural and industrial design specifications.

- Digitalization in Manufacturing: Adoption of Industry 4.0 principles, including IoT-enabled machinery, AI-driven quality control, and advanced CAD/CAM software for precision manufacturing and reduced lead times.

- Global Supply Chain Resilience: Emphasis on diversifying supply chains and building robust logistics networks to mitigate risks associated with geopolitical events and trade disruptions.

Technical Specifications and Parameters

Understanding the technical specifications of round hole perforated metal sheet is crucial for optimal selection and performance. Key parameters include material grade, sheet thickness, hole diameter, pitch, open area, and margin.

| Parameter | Standard Range | Common Materials | Testing Standards |

|---|---|---|---|

| Sheet Thickness (Gauge) | 0.3 mm - 10 mm (28 ga - 3/8 in) | Carbon Steel, Stainless Steel (304, 316L), Aluminum | ASTM A36/A240, EN 10025/10088 |

| Hole Diameter | 0.8 mm - 100 mm (1/32 in - 4 in) | Galvanized Steel, Copper, Brass | ISO 3310, ASTM E2016 |

| Pitch (Distance center-to-center) | Minimum 1.5 Hole Diameter | Titanium, Various Alloys | Internal QC, Client Specs |

| Open Area | Typically 20% - 70% | Calculated per ASTM E2016 | |

| Hole Pattern | Staggered (60°, 45°), Straight Row (90°) | ||

| Sheet Size | Up to 2000mm x 6000mm (custom sizes available) |

The open area, defined as the percentage of the total sheet area that is perforated, significantly impacts fluid flow, light transmission, and acoustic properties. For example, a higher open area (e.g., 60-70%) is preferred for filtration and ventilation, while a lower open area (e.g., 20-30%) offers greater structural strength for architectural or security applications.

Diverse Application Scenarios

The versatility of round perforated sheet makes it a staple across numerous industries:

- Filtration and Separation: Used in industrial strainers, filter screens, centrifuge baskets, and as support for filter media in water treatment, chemical processing, and food production. Its precise hole sizes ensure effective particle separation.

- Architectural and Decorative: Applied as façade cladding, sunscreens, balustrades, ceilings, and infill panels. The aesthetic appeal of round hole perforated metal provides a modern, sophisticated look while offering light diffusion and ventilation.

- Acoustic Control: Employed in sound-absorbing panels and enclosures, where the perforations help dissipate sound waves, reducing noise levels in industrial environments, concert halls, and office spaces.

- Sifting and Screening: Critical in mining, quarrying, and agriculture for sizing aggregates, minerals, grains, and seeds efficiently.

- Security and Protection: Used in security screens, machine guards, and protective barriers. The material offers robust protection while maintaining visibility and ventilation.

- HVAC and Ventilation: Integrated into air diffusers, grilles, and protective covers for heating, ventilation, and air conditioning systems, ensuring optimal airflow and preventing debris ingress.

Technical Advantages of Round Perforated Steel Sheet

The widespread adoption of round perforated metal sheet is attributed to its significant technical advantages:

- High Strength-to-Weight Ratio: By removing material strategically, perforated sheets offer structural integrity with reduced weight compared to solid sheets, leading to easier handling and lower material costs.

- Excellent Ventilation and Airflow: The open area facilitates efficient air and gas flow, crucial for cooling systems, ventilation panels, and heat dissipation in electronic enclosures.

- Superior Filtration and Separation: Precise and uniform hole sizes enable accurate separation of solids from liquids or gases, vital for numerous industrial processes.

- Corrosion Resistance: Available in stainless steel (e.g., 316L for marine or chemical environments) or galvanized steel, offering excellent resistance to rust and chemical degradation, extending service life significantly.

- Aesthetic Versatility: The uniform pattern of round holes provides a clean, modern look, enhancing architectural designs and offering opportunities for creative visual effects.

- Acoustic Performance: When combined with insulating materials, perforated sheets contribute significantly to noise reduction, essential for workplace safety and comfort.

- Energy Saving: In architectural applications, perforated screens can act as sunshades, reducing solar heat gain and lowering cooling costs. For filtration, optimized open areas reduce pressure drop, leading to energy savings in pumping or fan systems.

Vendor Comparison and Selection Criteria

Selecting the right supplier for round perforated steel sheet is critical for project success. Key factors for comparison include manufacturing capabilities, quality assurance, certification, lead times, and customer support.

| Feature | Leading Supplier A (e.g., ZT Wire Mesh) | Supplier B | Supplier C |

|---|---|---|---|

| Certifications & Standards | ISO 9001:2015, CE, ASTM E2016 | ISO 9001:2008 | Basic Quality Control |

| Customization Capability | Extensive (Material, Hole Size, Pitch, Shape, Finishes) | Moderate (Standard sizes, limited finishes) | Limited (Off-the-shelf only) |

| Lead Time (Standard Orders) | 5-10 business days | 10-15 business days | 20+ business days |

| After-Sales Support | Dedicated Technical Support, 24/7 Availability | Email/Phone Support during business hours | Limited or no support |

| Typical Warranty | 1-5 Years (Product specific) | 1 Year | None |

| Client Feedback (Simulated) | "Exceptional quality, precise cuts, fast delivery for large custom orders." | "Standard product, sometimes delays." | "Cost-effective for basic needs." |

Reputable manufacturers, like ZT Wire Mesh, often hold certifications like ISO 9001:2015, signifying a robust quality management system. Partnerships with major industrial clients and a track record of several decades in service further validate their authoritativeness.

Customized Solutions for Unique Requirements

While standard round perforated metal sheet products meet many needs, specialized projects often demand bespoke solutions. Leading manufacturers offer comprehensive customization options, including:

- Material Specificity: Custom alloys, specialized stainless steel grades (e.g., Duplex, Super Duplex) for extreme environments, or non-ferrous metals like copper or brass for specific conductivity or aesthetic needs.

- Unique Perforation Patterns: Beyond standard staggered or straight patterns, custom hole arrangements, varied hole sizes within a single sheet, or specialized open area percentages to achieve precise flow rates or visual effects.

- Advanced Fabrication: Complex forming (cylindrical, conical shapes), welding of multi-part assemblies, integrated framing, or specialized edge treatments for ease of installation and enhanced structural integrity.

- Specialized Finishes: Custom powder coating colors, anti-microbial coatings for medical or food processing applications, or specialized surface treatments for enhanced UV resistance or anti-graffiti properties.

Partnering with a supplier offering robust engineering and design support ensures that customized round hole perforated metal sheet solutions are precisely tailored to the project's exact functional and aesthetic demands.

Application Case Studies

Real-world applications showcase the practical benefits and adaptability of round perforated steel sheet:

Case Study 1: Noise Abatement in a Manufacturing Facility

A heavy machinery manufacturing plant faced severe noise pollution, impacting worker safety and compliance. Engineers designed acoustic panels using 2mm thick galvanized round perforated steel sheet with a 30% open area, backed by sound-absorbing mineral wool. The sheets were strategically installed as ceiling and wall panels. Post-installation, noise levels were reduced by an average of 15 dB across critical work zones, significantly improving occupational health conditions and meeting stringent environmental regulations.

Case Study 2: Architectural Facade for a Modern Office Building

A high-rise office building in a sunny climate required an external facade that provided sun shading, ventilation, and a distinctive aesthetic. Large panels of 3mm thick aluminum round perforated metal, anodized in a bronze finish, were selected. The custom perforation pattern allowed for varying degrees of transparency, creating dynamic visual effects while significantly reducing solar heat gain by 25%. This resulted in substantial energy savings on air conditioning and enhanced occupant comfort.

Case Study 3: Grain Drying and Storage Facilities

In large-scale agricultural operations, efficient grain drying and aeration are paramount. Robust round perforated steel sheet made from heavy-gauge galvanized steel is employed as flooring in grain silos and drying beds. The uniform 2.5mm holes ensure optimal airflow to prevent moisture accumulation and spoilage, while the strength of the steel supports massive grain loads. This application directly contributed to minimizing post-harvest losses and ensuring grain quality.

Frequently Asked Questions (FAQ)

Our lead times vary based on complexity and quantity. For standard materials and designs, expect 5-10 business days. Highly customized or large-volume orders may require 2-4 weeks. We always provide an estimated delivery schedule upon quotation. Expedited options are available for urgent projects.

We offer a comprehensive warranty, typically ranging from 1 to 5 years, depending on the product material and finish. This warranty covers manufacturing defects and material integrity under normal operating conditions. Detailed warranty terms are provided with each order.

Our manufacturing facilities are ISO 9001:2015 certified, adhering to strict quality management protocols. We conduct rigorous inspections at every stage, from raw material procurement to final product shipment. All products meet or exceed relevant international standards like ASTM, ANSI, and EN, verified through in-house testing and third-party certifications where required.

Our commitment extends beyond delivery. We provide dedicated technical support, available via phone and email. Our team is ready to assist with installation queries, performance optimization, and any post-purchase concerns to ensure long-term satisfaction and optimal product performance.

Conclusion: The Enduring Value of Round Perforated Steel Sheet

The continuous evolution of industrial and architectural demands underscores the enduring relevance of round perforated steel sheet. Its combination of structural integrity, aesthetic flexibility, and functional adaptability makes it a superior choice for an extensive array of applications. By understanding its meticulous manufacturing processes, technical specifications, and diverse application benefits, industries can leverage this versatile material to achieve optimal performance, durability, and cost-efficiency. Partnering with a reputable manufacturer that prioritizes quality, customization, and comprehensive support ensures that projects benefit from the highest standards of this essential industrial component.

References

- ASTM E2016-15, Standard Specification for Industrial Woven Wire Cloth and Perforated Plate Used for Screening Purposes, ASTM International.

- ISO 9001:2015, Quality management systems — Requirements, International Organization for Standardization.

- Metals Handbook, Vol. 14: Forming and Forging, ASM International.

- "The Engineering Design of Perforated Metal Panels for Architectural Applications," Journal of Architectural Engineering, American Society of Civil Engineers.

- "Corrosion Resistance of Stainless Steels," NACE International.

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.