Jun . 26, 2024 00:42

Back to list

Copper Sheet Metal with Perforations A Versatile Material for Industrial Applications

Perforated Copper Sheet Metal A Versatile Material for Industrial and Decorative Uses

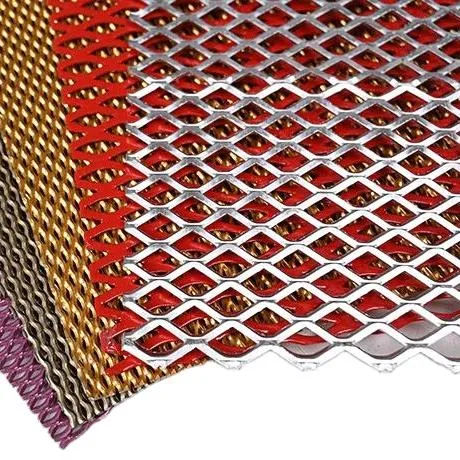

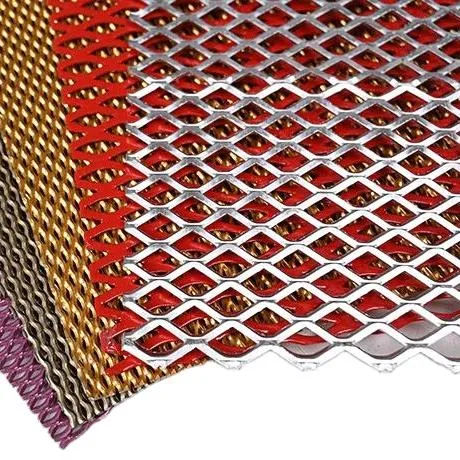

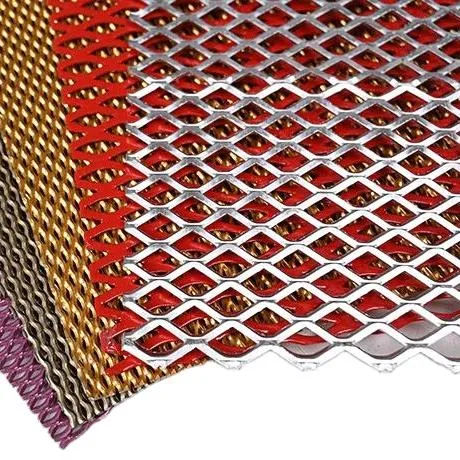

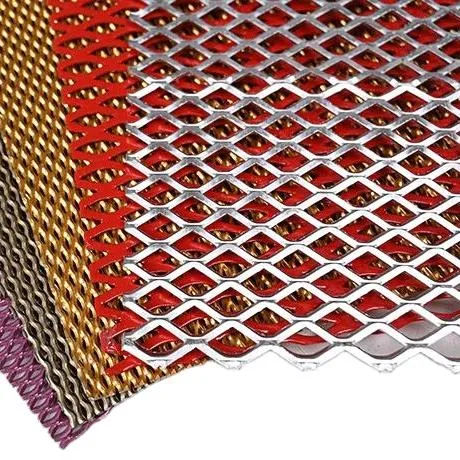

Copper, a reddish-brown metal known for its excellent electrical conductivity and heat transfer properties, has been used by humans for over 10,000 years. One of its many forms, the perforated copper sheet metal, offers unique advantages that make it an indispensable material in various industries as well as for decorative purposes.

Perforated copper sheets are produced by creating holes or openings in thin sheets of copper using specialized machinery. These holes can vary in size, shape, and pattern, depending on the application. The process of perforation not only changes the physical appearance of the metal but also its functional attributes, such as weight reduction and increased ventilation.

In the industrial sector, perforated copper sheets are widely used in filtration systems where their ability to allow fluids or gases to pass through while trapping solid particles is essential. They serve as effective filters in oil and water purification systems, chemical processes, and even in some types of machinery where cooling is required. The durability of copper ensures that these sheets withstand corrosive environments often present in such applications.

Moreover, the thermal conductivity of copper makes perforated sheets ideal for heat exchangers and radiators. The holes facilitate airflow, enhancing the efficiency of heat dissipation, which is crucial in electronic devices and industrial machines to prevent overheating.

Apart from its functional roles, perforated copper sheet metal is increasingly popular in architectural and interior design

Apart from its functional roles, perforated copper sheet metal is increasingly popular in architectural and interior design Apart from its functional roles, perforated copper sheet metal is increasingly popular in architectural and interior design

Apart from its functional roles, perforated copper sheet metal is increasingly popular in architectural and interior design

Apart from its functional roles, perforated copper sheet metal is increasingly popular in architectural and interior design

Apart from its functional roles, perforated copper sheet metal is increasingly popular in architectural and interior design perforated copper sheet metal. Designers appreciate the visual interest created by the play of light and shadow through the perforations. This material can be seen in facades, ceilings, and room dividers, adding a modern yet warm aesthetic to spaces. The timeless appeal of copper, coupled with the textural contrast of the perforations, provides designers with a versatile medium to craft unique and captivating installations.

The manufacturing process of perforated copper sheets is precise and can be tailored to specific needs. Laser cutting technology allows for intricate patterns and precise hole placement, expanding the creative possibilities for designers and engineers alike. Additionally, because copper is recyclable, using perforated copper sheets aligns with sustainable practices and reduces environmental impact.

In conclusion, perforated copper sheet metal combines the inherent benefits of copper with the functionality of perforation. It serves both as a robust industrial material and a beautiful decorative element. As technology advances and design trends evolve, the applications for perforated copper sheets are likely to grow, ensuring their place in various facets of our built environment and industrial processes.

perforated copper sheet metal. Designers appreciate the visual interest created by the play of light and shadow through the perforations. This material can be seen in facades, ceilings, and room dividers, adding a modern yet warm aesthetic to spaces. The timeless appeal of copper, coupled with the textural contrast of the perforations, provides designers with a versatile medium to craft unique and captivating installations.

The manufacturing process of perforated copper sheets is precise and can be tailored to specific needs. Laser cutting technology allows for intricate patterns and precise hole placement, expanding the creative possibilities for designers and engineers alike. Additionally, because copper is recyclable, using perforated copper sheets aligns with sustainable practices and reduces environmental impact.

In conclusion, perforated copper sheet metal combines the inherent benefits of copper with the functionality of perforation. It serves both as a robust industrial material and a beautiful decorative element. As technology advances and design trends evolve, the applications for perforated copper sheets are likely to grow, ensuring their place in various facets of our built environment and industrial processes.

Apart from its functional roles, perforated copper sheet metal is increasingly popular in architectural and interior design

Apart from its functional roles, perforated copper sheet metal is increasingly popular in architectural and interior design

Apart from its functional roles, perforated copper sheet metal is increasingly popular in architectural and interior design

Apart from its functional roles, perforated copper sheet metal is increasingly popular in architectural and interior design perforated copper sheet metal. Designers appreciate the visual interest created by the play of light and shadow through the perforations. This material can be seen in facades, ceilings, and room dividers, adding a modern yet warm aesthetic to spaces. The timeless appeal of copper, coupled with the textural contrast of the perforations, provides designers with a versatile medium to craft unique and captivating installations.

The manufacturing process of perforated copper sheets is precise and can be tailored to specific needs. Laser cutting technology allows for intricate patterns and precise hole placement, expanding the creative possibilities for designers and engineers alike. Additionally, because copper is recyclable, using perforated copper sheets aligns with sustainable practices and reduces environmental impact.

In conclusion, perforated copper sheet metal combines the inherent benefits of copper with the functionality of perforation. It serves both as a robust industrial material and a beautiful decorative element. As technology advances and design trends evolve, the applications for perforated copper sheets are likely to grow, ensuring their place in various facets of our built environment and industrial processes.

perforated copper sheet metal. Designers appreciate the visual interest created by the play of light and shadow through the perforations. This material can be seen in facades, ceilings, and room dividers, adding a modern yet warm aesthetic to spaces. The timeless appeal of copper, coupled with the textural contrast of the perforations, provides designers with a versatile medium to craft unique and captivating installations.

The manufacturing process of perforated copper sheets is precise and can be tailored to specific needs. Laser cutting technology allows for intricate patterns and precise hole placement, expanding the creative possibilities for designers and engineers alike. Additionally, because copper is recyclable, using perforated copper sheets aligns with sustainable practices and reduces environmental impact.

In conclusion, perforated copper sheet metal combines the inherent benefits of copper with the functionality of perforation. It serves both as a robust industrial material and a beautiful decorative element. As technology advances and design trends evolve, the applications for perforated copper sheets are likely to grow, ensuring their place in various facets of our built environment and industrial processes. Latest news

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.

Email addressSIGN UP