Industry Trends and the Evolving Landscape of Site Security

The demand for robust, reliable, and rapidly deployable site security solutions continues to escalate across various sectors, particularly within Australia's booming construction, infrastructure development, and event management industries. Project managers and site supervisors are increasingly seeking flexible fencing systems that not only comply with stringent safety regulations but also offer efficiency, durability, and cost-effectiveness. This environment has fostered significant innovation in temporary fencing technologies, moving beyond basic barriers to engineered solutions designed for specific environmental and operational challenges.

In Australia, the regulatory framework, notably Australian Standard AS 4687-2007 for Temporary Fencing and Hoarding, sets a high bar for product performance, installation, and wind loading resistance. This standard drives the market towards specialized products that guarantee compliance and enhance site safety. The trend points towards systems that are quick to erect and dismantle, highly portable, resistant to harsh weather conditions, and environmentally sustainable through reusability. Within this context, the Australia Temporary Fence has emerged as a cornerstone solution, specifically engineered to meet these rigorous local demands while offering global applicability.

The market is also witnessing a shift towards suppliers capable of offering not just standard products but also comprehensive solutions, including gate systems, pedestrian barriers, and specialized accessories, alongside robust logistical and support services. Digital integration for inventory management, rapid deployment planning, and real-time site monitoring are becoming differentiating factors among leading providers. This holistic approach ensures that temporary fencing is viewed not merely as a perimeter, but as an integral component of overall project management and risk mitigation strategies.

Precision Manufacturing Process of Temporary Fencing

The manufacturing of high-quality temporary fencing, particularly for demanding markets like Australia, involves a meticulous process designed to ensure structural integrity, longevity, and adherence to performance standards. Our process integrates advanced materials science with precise engineering techniques to produce a superior product.

Process Flow:

- Material Sourcing & Preparation: We utilize high-grade, low-carbon steel wire and galvanized steel tubing (typically 32mm or 42mm OD) as primary materials. The steel is rigorously inspected for chemical composition and mechanical properties, ensuring it meets ASTM A513 or equivalent international standards. Wire coils are unwound and straightened to prepare for mesh welding.

- Mesh Welding (Automated): State-of-the-art automated welding machines are employed to precisely weld the horizontal and vertical wires, forming the mesh panel. This resistance welding technique ensures strong, consistent joints, critical for panel rigidity. Common mesh openings are 60x150mm or 75x150mm, using wire diameters from 3mm to 5mm.

- Frame Fabrication (CNC & Welding): The galvanized steel tubing is cut to precise lengths using CNC machining to ensure dimensional accuracy. These tubes are then bent and assembled into the rectangular frame. Robotic or skilled manual MIG/TIG welding is applied at all connection points, creating a robust, unitary frame structure. The frame typically features anti-climb mesh infill for enhanced security.

- Panel-to-Frame Integration: The welded mesh panel is then securely welded into the fabricated frame. This crucial step is performed with care to prevent any damage to the galvanized coating of the frame or mesh, maintaining corrosion resistance. All welds are clean and free of burrs.

- Surface Treatment & Finishing: While primary materials are pre-galvanized, any areas where welding has occurred or where the zinc coating may have been compromised are meticulously re-treated with a cold galvanizing compound or a zinc-rich primer to maintain full corrosion protection. This ensures a consistent protective layer across the entire panel. For additional durability or specific aesthetic requirements, powder coating can be applied over the galvanized surface.

- Quality Control & Testing: Each batch undergoes rigorous quality control. This includes dimensional checks, weld integrity testing (e.g., destructive pull tests on sample welds), and visual inspections for coating quality. Compliance with Australian Standard AS 4687-2007 is verified through structural integrity tests, specifically related to panel rigidity and resistance to displacement under force. Salt spray testing (ASTM B117) is periodically performed to confirm corrosion resistance, simulating harsh environmental conditions.

- Packaging & Dispatch: Finished panels are carefully stacked and secured, often bundled with protective wrapping, to prevent damage during transit. Bases and clamps are packaged separately for ease of assembly on site.

Materials & Service Life:

Our Australia Temporary Fence systems are primarily constructed from hot-dipped or pre-galvanized steel, offering exceptional resistance to corrosion, rust, and UV degradation. This material choice, combined with expert welding and finishing, contributes to a typical service life exceeding 10-15 years under normal operational conditions, significantly reducing the total cost of ownership through repeated use and minimal maintenance.

Target Industries & Advantages:

These robust temporary fences are indispensable across a wide range of industries including:

- Construction & Civil Engineering: Securing sites, controlling access, protecting public from hazards.

- Mining & Resources: Delineating hazardous zones, perimeter security for remote operations.

- Event Management: Crowd control, defining perimeters for festivals, concerts, and sporting events.

- Public Works & Utilities: Safety barriers around excavations, roadworks, and infrastructure projects.

- Demolition Projects: Containing debris, restricting unauthorized entry.

The technical advantages in these scenarios include rapid deployment, superior corrosion resistance, enhanced safety through anti-climb mesh, and high reusability. For instance, in an energy-saving context, the galvanized finish significantly reduces maintenance requirements and the need for frequent replacement, contributing to lower lifecycle costs and a reduced environmental footprint.

Technical Specifications and Parameters

Understanding the precise technical specifications of a temporary fencing system is critical for ensuring compliance, adequate security, and operational efficiency. Our Australia Temporary Fence systems are designed with these parameters in mind, meeting or exceeding industry benchmarks, particularly AS 4687-2007.

| Parameter | Description/Value | Compliance/Standard |

|---|---|---|

| Panel Height | 2100 mm (2.1 meters) is standard. Other heights available upon request. | AS 4687-2007 requirements for minimum height. |

| Panel Width | 2400 mm (2.4 meters) is standard. | Optimized for handling and coverage. |

| Mesh Opening | 60 x 150 mm or 75 x 150 mm (Anti-climb design). | Reduces climbability and deters unauthorized entry. |

| Wire Diameter | 3.0 mm (horizontal) / 4.0 mm (vertical) or 4.0 mm / 5.0 mm. | Ensures strength and rigidity against external forces. |

| Frame Pipe Diameter | 32 mm OD or 42 mm OD. | Structural integrity, wind resistance. |

| Frame Pipe Wall Thickness | 1.5 mm, 2.0 mm, or 2.5 mm. | Crucial for durability and impact resistance. |

| Surface Treatment | Hot-dipped galvanized (minimum 42 microns) or Pre-galvanized + Zinc rich paint weld repairs. | ISO 1461 for hot-dipped galvanizing, excellent corrosion resistance. |

| Fence Base Type | Blow-moulded plastic base (high-visibility colors), typically 600x220x150mm, filled with concrete. | Ensures stability, prevents tipping, high visibility for safety. |

| Clamps/Couplers | Galvanized steel clamps with anti-tamper bolts/nuts. | Secure panel-to-panel connection, enhancing system integrity. |

| Wind Load Resistance | Engineered to withstand specific wind speed categories (e.g., up to W33 for specific configurations). | Compliance with AS 4687-2007 for stability in wind. Engineering certification available. |

These parameters collectively define a high-performance temporary fencing system. The specified wire diameters and mesh openings contribute to both anti-climb properties and material efficiency. The robust frame pipe diameters and wall thicknesses are critical for resisting impact and wind loading, key considerations in exposed Australian environments. The hot-dipped galvanized finish ensures long-term corrosion resistance, extending the product’s lifecycle and reducing the need for maintenance or premature replacement.

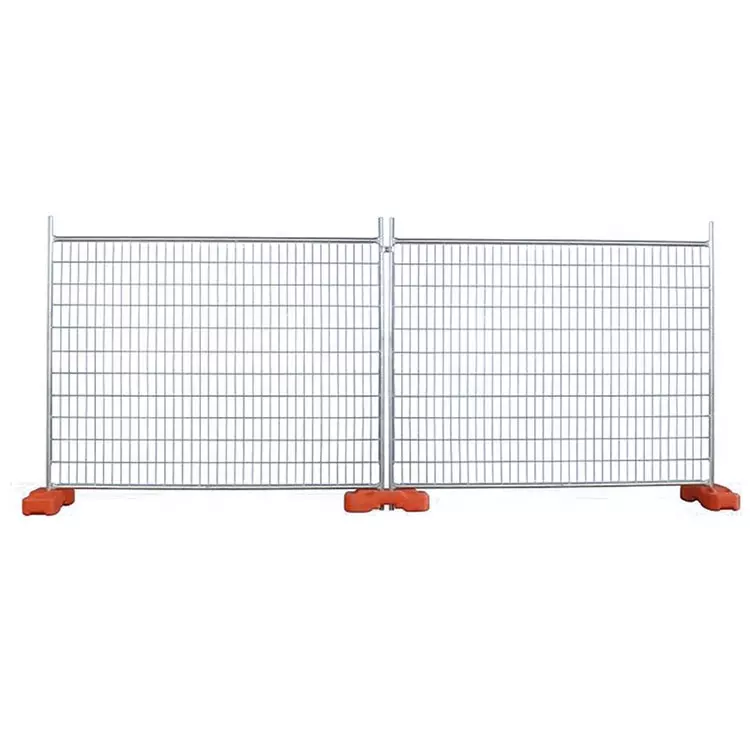

Image: Detailed view of a typical Australia Temporary Fence panel showing mesh and frame construction.

Diverse Application Scenarios and Technical Advantages

The versatility and inherent technical advantages of our Australia Temporary Fence solutions make them indispensable across a broad spectrum of applications, from urban development to remote industrial sites. Their design prioritizes rapid deployment, robust security, and adaptability, critical factors for dynamic project environments.

Typical Application Scenarios:

- Construction Sites: Essential for perimeter security, restricting unauthorized access, protecting the public from hazards, and delineating specific work zones within large sites. They effectively manage pedestrian and vehicle flow, enhancing overall site safety.

- Event Management: From music festivals and sporting events to public gatherings and exhibitions, temporary fencing is crucial for crowd control, defining entry/exit points, creating secure perimeters, and managing queues. The quick setup and dismantle times are particularly valuable here.

- Public Works and Infrastructure Projects: For roadworks, bridge construction, utility repairs, and other civil engineering projects, these fences provide immediate safety barriers around excavations, equipment, and hazardous areas, safeguarding both workers and the general public.

- Mining and Resources: In remote and often harsh environments, temporary fences are used to secure equipment, delineate hazardous blast zones, restrict access to mine shafts or processing areas, and provide general perimeter security for temporary camps or exploration sites. Their durability and corrosion resistance are paramount in these conditions.

- Demolition Projects: Containment of debris, restriction of access to unstable structures, and public safety are key concerns. Temporary fences offer a flexible and strong barrier to manage these risks.

- Emergency and Disaster Relief: Quick deployment for securing affected areas, establishing relief perimeters, and managing aid distribution.

Core Technical Advantages:

- Rapid Deployment & Mobility: Designed for modular assembly, allowing for quick installation and dismantling without specialized tools or foundations. This significantly reduces labor costs and project timelines, offering unparalleled flexibility for dynamic site requirements.

- Superior Security & Access Control: Featuring anti-climb mesh (small openings), secure panel-to-panel clamping, and sturdy bases, our fences effectively deter unauthorized entry. Integration with temporary gates further enhances controlled access.

- Exceptional Durability & Corrosion Resistance: Constructed from hot-dipped galvanized steel, these fences offer outstanding protection against rust and weathering, crucial for the diverse and often harsh Australian climate. This extends product lifespan and maintains aesthetic integrity.

- Compliance with Australian Standards: Engineered and tested to meet or exceed AS 4687-2007, ensuring they comply with local safety and structural integrity requirements, which is vital for legal and insurance purposes on any Australian project.

- Cost-Effectiveness & Reusability: Their robust construction allows for multiple uses across different projects. This reusability, coupled with minimal maintenance, translates into significant long-term cost savings compared to permanent or less durable temporary solutions.

- Wind Load Stability: Engineered designs, often with optional bracing and secure footings, provide enhanced stability against high winds, a critical feature for exposed sites or during adverse weather conditions.

These technical advantages ensure that our temporary fencing systems provide not just a physical barrier, but a comprehensive solution for site management, safety compliance, and operational efficiency, proving their value across Australia's demanding industrial and commercial landscapes.

Customized Solutions for Unique Project Demands

While standard Australia Temporary Fence panels are highly versatile, many projects present unique challenges that necessitate tailored solutions. We specialize in providing customized temporary fencing systems designed to integrate seamlessly with specific site conditions, security protocols, and aesthetic requirements.

Key Customization Options Include:

- Panel Dimensions: Custom heights and widths can be fabricated to fit non-standard site boundaries, integrate with existing structures, or meet specific regulatory requirements where standard 2.1m x 2.4m panels may not suffice.

- Mesh Specifications: While anti-climb mesh (60x150mm or 75x150mm) is standard, options for smaller mesh apertures (e.g., 50x50mm) can provide enhanced security against small object passage or for specific animal control needs. Heavier gauge wire can be used for increased rigidity and impact resistance.

- Frame and Pipe Thickness: For projects in extremely high wind zones or those requiring superior resistance to forced entry, custom frame pipe diameters (e.g., 48mm OD) and increased wall thicknesses (e.g., 3.0mm) can be specified, providing enhanced structural stability.

- Integrated Gate Systems: Custom pedestrian and vehicle gates can be designed and fabricated to match the fence line, including swing gates, sliding gates, and bi-fold options. These can be equipped with various locking mechanisms, access control provisions, and robust hinge systems for high-traffic areas.

- Specialized Bases & Stability Solutions: Beyond standard blow-moulded concrete-filled bases, options include steel bases for harsher conditions, wheel-mounted bases for dynamic perimeters, or more extensive bracing systems for extreme wind load requirements or where hoarding is attached.

- Surface Finishes & Branding: While galvanizing is standard, powder coating in specific RAL colors can be applied for aesthetic integration with corporate branding or urban environments. Hoarding panels can be integrated for privacy or marketing messages.

- Accessory Integration: Custom clamps, handrails, shade cloth attachments, barbed wire extensions, or specialized signage mounts can be incorporated to meet distinct functional requirements.

Our engineering team collaborates closely with clients from initial concept to deployment, providing CAD drawings and structural calculations to ensure that customized temporary fencing solutions not only meet but exceed expectations for performance, safety, and compliance with relevant Australian standards.

Vendor Comparison: Selecting the Right Partner

Choosing a supplier for temporary fencing is a strategic decision that impacts project timelines, safety, and budget. A comprehensive vendor comparison goes beyond initial price, evaluating critical factors that ensure long-term value and reliability. Here's a framework for evaluating suppliers for your Australia Temporary Fence needs.

| Criterion | Consideration for Decision Makers | Our Commitment/Advantage |

|---|---|---|

| Product Quality & Materials | Are materials high-grade? What is the galvanization standard? Are welds robust and consistent? Inferior materials lead to premature failure and replacement costs. | Utilize hot-dipped galvanized steel, certified to ISO standards. Rigorous QC on wire, frame, and welds. |

| Compliance & Certifications | Does the product meet AS 4687-2007? Are engineering certificates available for wind loading? Non-compliance poses significant legal and safety risks. | Fully compliant with AS 4687-2007. Engineering certifications provided for structural integrity and wind resistance. |

| Customization Capabilities | Can the supplier tailor solutions (e.g., custom sizes, gate systems, branding) to unique project needs? Generic products may not fully address complex site requirements. | Extensive customization options, supported by in-house engineering and design expertise. |

| Lead Times & Logistics | What are typical production and delivery times? Can they handle large orders efficiently? Delays can halt projects and incur significant costs. | Streamlined production process, efficient supply chain management, and established logistics partners for timely delivery. |

| After-Sales Support & Warranty | What kind of warranty is offered? Is technical support available post-purchase? Reliable support is crucial for addressing unforeseen issues. | Comprehensive warranty and dedicated customer support team. Clear documentation and accessible technical assistance. |

| Reputation & Experience | How long has the vendor been in business? What do client testimonials or case studies indicate about their reliability? A proven track record minimizes risk. | Years of industry experience, extensive portfolio of successful projects, and strong client partnerships globally and within Australia. |

| Cost-Effectiveness (TCO) | Beyond the purchase price, consider the total cost of ownership (TCO), including durability, reusability, maintenance, and potential replacement frequency. | Premium product quality ensuring extended service life and high reusability, leading to a superior return on investment and lower TCO. |

Image: A fully installed section of Australia Temporary Fence demonstrating robust construction.

By diligently evaluating these criteria, B2B decision-makers can identify a partner that not only supplies fencing but provides a comprehensive, reliable, and compliant security solution tailored to their operational needs. Our commitment to these standards ensures that we stand as a trusted supplier in the temporary fencing market.

Application Case Studies: Real-World Deployments

The efficacy and reliability of Australia Temporary Fence systems are best demonstrated through their successful deployment in real-world scenarios. These case studies highlight our capability to provide tailored solutions that meet complex project demands, ensure compliance, and enhance site safety and security.

Case Study 1: Major Urban Infrastructure Project, Sydney

Client: Tier-1 Construction Company, delivering a multi-billion-dollar rail upgrade.

Challenge: The project required a highly secure, rapidly reconfigurable perimeter around multiple urban construction zones, often adjacent to high-traffic pedestrian areas and active public transport lines. Key concerns included public safety, anti-climb security, noise reduction (through integrated hoarding), and the need for frequent reconfiguration as project stages evolved.

Solution: We supplied over 15 kilometers of customized Australia Temporary Fence panels, incorporating a mix of standard anti-climb mesh panels and integrated hoarding panels for noise attenuation and privacy. Custom-fabricated vehicle and pedestrian gates with heavy-duty locking mechanisms were deployed at all access points. Our engineering team provided detailed wind load calculations for various configurations and ensured all installations met AS 4687-2007. The modular design allowed for rapid relocation of fence lines every few weeks, minimizing disruption and maximizing operational flexibility.

Outcome: The client reported zero breaches of the perimeter over an 18-month period. Public complaints regarding site safety were significantly reduced due to the robust and clearly defined barriers. The reusability of the panels across different project stages led to substantial cost savings compared to alternative solutions. Project Manager Feedback: "The reliability and adaptability of these fences were paramount to keeping our complex urban site secure and compliant. The quick turnaround for reconfigurations saved us critical time and labor."

Case Study 2: Remote Mining Exploration Camp, Western Australia

Client: Leading global mining corporation operating in a remote, arid region.

Challenge: Establishing a secure perimeter around a temporary exploration camp, including accommodation units, equipment storage, and processing areas. The environment presented extreme challenges: high temperatures, abrasive dust, and the need for robust security against both human and wildlife intrusion. Deployment had to be rapid and require minimal site preparation.

Solution: We provided heavy-duty Australia Temporary Fence panels with enhanced galvanization for superior corrosion and abrasion resistance, mounted on specialized steel bases designed for uneven terrain. The mesh infill was chosen for maximum anti-climb properties and to withstand potential animal interactions. Fence lines were equipped with robust bracing to maintain stability against high desert winds. Given the remote location, panels were bundled for efficient transport and installation crews were provided with clear, concise assembly instructions.

Outcome: The fence system was deployed within days of arrival, providing an immediate and effective security perimeter. The robust construction and specialized bases performed exceptionally well in the harsh environment, requiring minimal maintenance. The client successfully secured their personnel and assets, with no security breaches reported over the course of the exploration phase. Operations Manager Feedback: "These fences were a critical component of our camp setup. Their durability in the harsh outback conditions was impressive, and the ease of installation was a huge benefit for our remote team."

Image: Australia Temporary Fence deployed on a construction site, demonstrating robust perimeter security.

Trustworthiness & Support: Your Partner in Site Security

Building long-term partnerships in the B2B sector requires not just high-quality products, but also unwavering commitment to customer support, transparent operations, and reliable service. We prioritize trust by ensuring clarity on product specifics, fulfillment processes, and post-purchase assistance.

Frequently Asked Questions (FAQ)

-

Q: What makes your Australia Temporary Fence compliant with Australian standards?

A: Our fences are engineered and tested to meet or exceed AS 4687-2007 Temporary Fencing and Hoarding, covering structural integrity, wind loading, and panel dimensions. We provide compliance documentation and engineering certificates upon request. -

Q: What is the expected lifespan of your temporary fencing?

A: With proper handling and maintenance, our hot-dipped galvanized fencing systems are designed for a service life of 10-15 years, ensuring multiple reuses across various projects due to their superior corrosion resistance. -

Q: Can the fences withstand high winds?

A: Yes, our temporary fences are designed with robust frames and bases. For specific wind load requirements, we can provide engineering specifications and recommend additional bracing solutions to ensure stability in high-wind conditions, complying with relevant local building codes. -

Q: Do you offer installation services or guidance?

A: While we primarily supply the products, we provide comprehensive installation guides and technical consultation. For larger projects, we can connect clients with trusted installation partners in their region. -

Q: What customization options are available?

A: We offer extensive customization, including bespoke panel dimensions, heavier gauge mesh/frames, integrated gates, specialized bases, and branding options like custom powder coating or hoarding attachments. Our team works with you to design a solution for your specific needs.

Lead Time and Fulfillment Details

Our manufacturing facilities operate with efficiency to ensure timely delivery. Standard orders for Australia Temporary Fence panels typically have a lead time of 2-4 weeks from order confirmation, depending on quantity and current production schedule. Customized orders may require additional time for design and fabrication, usually 4-6 weeks. We maintain strategic partnerships with global logistics providers to ensure reliable and cost-effective shipping to your project site, with detailed tracking and communication throughout the transit process. Expedited options can be discussed for urgent requirements.

Warranty Commitments

We stand behind the quality and durability of our products. All our temporary fencing systems come with a comprehensive 5-year warranty against manufacturing defects and premature corrosion under normal use conditions. This commitment reflects our confidence in the materials and craftsmanship, providing our clients with peace of mind and protecting their investment.

Dedicated Customer Support

Our dedicated customer support team is available to assist with inquiries, technical specifications, order processing, and after-sales support. From initial consultation to post-delivery assistance, we provide expert guidance to ensure your project's success. You can reach our support specialists via phone, email, or through our website's dedicated contact portal during business hours. We are committed to prompt and effective resolution of any issues or questions you may have.

Image: A worker setting up a robust Australia Temporary Fence system, highlighting ease of assembly.

Conclusion

The strategic importance of robust temporary fencing cannot be overstated in modern B2B operations, particularly within the dynamic Australian market. Our Australia Temporary Fence solutions are engineered to transcend basic perimeter security, offering a comprehensive system that integrates high-grade materials, precision manufacturing, and rigorous compliance with AS 4687-2007. This ensures not only superior site safety and security but also contributes to operational efficiency, cost-effectiveness through reusability, and environmental sustainability. By providing customizable options, strong vendor support, and a commitment to transparency, we empower decision-makers with reliable, long-term solutions that meet the evolving demands of construction, events, and industrial projects across Australia.

References

- Standards Australia. AS 4687-2007: Temporary fencing and hoardings. SAI Global.

- ISO 1461:2009. Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods. International Organization for Standardization.

- ASTM B117-19. Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International.

- National Construction Code (NCC) 2022. Australian Building Codes Board (ABCB).

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.