Industry Trends in Temporary Fencing for the Australian Market

The Australian temporary fencing market is experiencing robust growth, driven by an escalating pipeline of infrastructure projects, a buoyant construction sector, and a dynamic events industry. As urban development continues at pace across major cities like Sydney, Melbourne, and Brisbane, the demand for reliable, compliant, and cost-effective site security and access control solutions has intensified. Regulatory compliance, particularly concerning worker safety and public liability on construction sites (e.g., adherence to AS 4687-2007), is a paramount driver, necessitating fencing systems that meet stringent performance and safety standards.

Key trends include a shift towards highly durable, reusable, and galvanized steel systems designed for extended service life, reducing overall project costs and environmental impact. There's also an increasing emphasis on integrated solutions, offering not just panels but also gates, bracing, and specialized bases that adapt to diverse ground conditions. Furthermore, the adoption of advanced manufacturing techniques is leading to higher quality, more consistent products with improved structural integrity and easier installation, enhancing operational efficiency for contractors and event organizers. The market increasingly values suppliers who can offer tailored solutions, swift deployment, and comprehensive after-sales support, underscoring the importance of selecting a reputable and experienced vendor for Australia Temporary Fence requirements.

The Manufacturing Process of Australia Temporary Fence

The production of high-quality temporary fencing systems, specifically the Australia Temporary Fence, involves a meticulous, multi-stage manufacturing process designed to ensure durability, structural integrity, and compliance with rigorous industry standards. This process leverages advanced metallurgical techniques and precision engineering to deliver a product capable of withstanding harsh Australian environmental conditions.

Materials Specification:

At the core of a robust Australia Temporary Fence is the selection of high-grade steel. Typically, low-carbon steel wire (Q195/Q235) is used for the mesh, offering an optimal balance of strength and ductility. The frame components, comprising uprights and horizontal rails, are constructed from pre-galvanized or hot-dip galvanized steel tubing (e.g., 32mm, 38mm, or 42mm OD), ensuring structural rigidity and foundational corrosion resistance. Galvanization is a critical step, often exceeding 42 microns of zinc coating for superior protection against rust and degradation in outdoor environments.

Manufacturing Process Flow:

- Wire Straightening and Cutting: High-tensile steel wire coils are unspooled, precisely straightened, and cut to the exact lengths required for the mesh panels. This stage utilizes automated machinery to ensure dimensional accuracy.

- Mesh Welding: The cut wires are then fed into a specialized resistance welding machine. This automated process fuses the horizontal and vertical wires at their intersections, creating a strong, uniform mesh panel with consistent aperture sizes (e.g., 60x150mm, 75x150mm). The welding ensures structural integrity and prevents unraveling.

- Frame Fabrication: Steel tubes for the frame are precisely cut, bent, and pre-drilled (if required for specific connection points). Welding techniques, such as MIG or TIG welding, are employed to assemble the frame components, creating a robust perimeter for the mesh. Quality checks ensure all welds are strong and free from defects.

- Panel Integration and Secondary Welding: The pre-welded mesh panel is then carefully positioned within the fabricated steel frame. It is securely welded to the frame at multiple points, typically on all four sides, to ensure maximum rigidity and prevent dislodgment, even under significant external pressure or impact.

- Hot-Dip Galvanization (Post-Welding): For superior corrosion resistance, the entire welded panel (frame and mesh) undergoes hot-dip galvanization. This process involves immersing the steel in a bath of molten zinc (typically at 450°C). The zinc metallurgically bonds with the steel, forming a durable, sacrificial coating that protects against rust and extends the service life significantly, often to 10-15 years or more in typical conditions. This meets standards such as AS/NZS 4680.

- Quality Control and Finishing: Post-galvanization, each panel undergoes rigorous inspection to ensure adherence to specified dimensions, mesh consistency, weld integrity, and galvanization thickness. Any sharp edges or imperfections are addressed. Accessories like plastic/concrete bases and clamps are prepared for packaging.

Testing Standards and Service Life:

Our manufacturing adheres strictly to international quality management systems, notably ISO 9001:2015, ensuring consistency and reliability across all production stages. For products destined for Australia, compliance with AS 4687-2007 (Temporary Fencing and Hoardings) is non-negotiable, dictating structural integrity, panel dimensions, and installation requirements. The hot-dip galvanized finish ensures an extended service life, typically projected for 10-15 years, significantly outperforming painted or electro-galvanized alternatives in outdoor and harsh environments.

Target Industries and Advantages:

The primary target industries for Australia Temporary Fence systems include construction (commercial, residential, infrastructure), mining and resources, event management, public works, and civil engineering. In these scenarios, the advantages are multifold:

- Corrosion Resistance: The hot-dip galvanized coating provides superior protection, crucial for coastal or high-humidity regions, minimizing maintenance and replacement costs.

- Rapid Deployment & Reusability: Modular design allows for quick installation and dismantling, crucial for dynamic project sites and events, fostering reusability across multiple projects.

- Enhanced Safety & Security: Robust construction and compliance with AS 4687-2007 ensure secure site perimeters, protecting personnel and the public, and safeguarding assets.

- Cost-Effectiveness: While initial investment might be higher than lesser-quality alternatives, the extended service life and reusability of hot-dip galvanized fencing offer significant long-term cost savings.

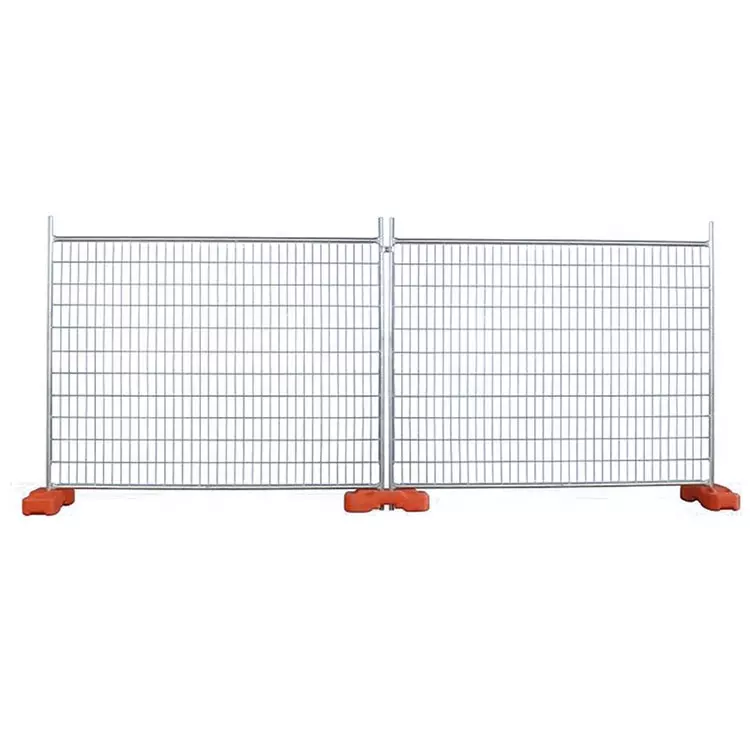

Figure 1: Typical panel and base components of a Australia Temporary Fence system.

Technical Specifications of Australia Temporary Fence

Understanding the precise technical parameters is crucial for optimal project planning and procurement. The following table details typical specifications for our high-performance Australia Temporary Fence panels, designed to meet Australian industry demands.

| Parameter | Specification | Notes/Standard Compliance |

|---|---|---|

| Panel Height (Standard) | 2100 mm (2.1 m) | Common height for security and compliance. |

| Panel Width (Standard) | 2400 mm (2.4 m) | Optimized for handling and coverage. |

| Mesh Wire Diameter | 3.0 mm - 4.0 mm | Varies based on strength requirement (e.g., 3.0mm internal, 4.0mm external). |

| Mesh Opening | 60 mm x 150 mm or 75 mm x 150 mm | Anti-climb design. |

| Frame Pipe Diameter | 32 mm OD, 38 mm OD, or 42 mm OD | Outer Diameter (OD), heavy-duty options available. |

| Frame Pipe Wall Thickness | 1.5 mm - 2.0 mm | Ensures structural rigidity. |

| Surface Treatment | Hot-Dip Galvanized | Minimum 42 microns zinc coating (AS/NZS 4680). |

| Panel Weight (Approx.) | 18 kg - 25 kg | Varies with mesh and frame specifications. |

| Base Type | Blow-moulded Plastic (HDPE) or Concrete Block | UV stabilized, heavy-duty for stability. |

| Clamp Type | Hot-dip galvanized steel or pressed steel | Secure panel-to-panel connection. |

Application Scenarios and Case Studies

The versatility and robust nature of Australia Temporary Fence systems make them indispensable across a broad spectrum of industries. Their modular design allows for rapid deployment and reconfiguration, addressing diverse operational needs from security perimeters to crowd control.

Typical Application Scenarios:

- Construction Sites: Essential for securing construction perimeters, preventing unauthorized access, containing debris, and demarcating hazardous zones. They are vital for compliance with OH&S regulations.

- Event Management: Utilized for crowd control at concerts, festivals, sporting events, and public gatherings. They define entry/exit points, restrict access to VIP areas, and manage pedestrian flow effectively.

- Mining and Industrial Sites: Crucial for establishing temporary exclusion zones, securing equipment storage areas, and managing access to active mining operations where safety is paramount.

- Public Works & Infrastructure Projects: Deployed around roadworks, utility repairs, and other civil engineering sites to ensure public safety, direct traffic, and protect ongoing work.

- Emergency Services & Disaster Relief: Quick to set up, they provide temporary barriers for emergency response, cordoning off dangerous areas, or managing distribution points.

Application Case Studies:

Case Study 1: Major CBD High-Rise Construction Project, Melbourne

A leading Australian construction firm faced the challenge of securing a multi-story CBD construction site in Melbourne, requiring robust perimeter security, public safety management, and aesthetic integration with urban surroundings. Our Australia Temporary Fence systems were chosen for their compliance with AS 4687-2007, superior hot-dip galvanized finish, and capability to be outfitted with branded shade cloth. Over 500 linear meters of fencing, including pedestrian and vehicle gates, were deployed within 48 hours. The fence's stability, even under significant wind loads, and its anti-climb mesh provided critical security, minimizing incidents of unauthorized access and enhancing public trust. The ease of relocation also proved beneficial as the project progressed through different phases.

Case Study 2: Regional Music Festival, New South Wales

An annual regional music festival required a comprehensive, flexible, and rapidly deployable fencing solution for crowd management, VIP area demarcation, and entry/exit control across a large outdoor venue. Over 1 kilometer of Australia Temporary Fence was supplied. The lightweight yet sturdy design, coupled with heavy-duty plastic bases, allowed festival staff to install and dismantle the entire perimeter in less than 24 hours. The galvanization ensured the fences withstood varied weather conditions throughout the event and were ready for immediate re-use at subsequent events, demonstrating excellent return on investment due to their durability and reusability. Customer feedback highlighted the ease of installation and the professional appearance of the fencing system.

Figure 2: Australia Temporary Fence panels deployed on a construction site for security and access control.

Technical Advantages & Performance Metrics

The technical superiority of our Australia Temporary Fence systems is rooted in stringent material selection, advanced manufacturing processes, and adherence to industry-leading standards. These elements collectively contribute to a product offering unparalleled performance and long-term value.

Key Technical Advantages:

- Superior Corrosion Resistance: Our fencing utilizes hot-dip galvanization after welding, providing a thick, uniform zinc coating (typically >42µm) that offers cathodic protection against rust and corrosion. This significantly extends the service life compared to pre-galvanized or electro-galvanized alternatives, especially in Australia's diverse and often harsh climates, including coastal regions.

- Exceptional Structural Integrity: The combination of heavy-gauge steel mesh wires (e.g., 3.0-4.0mm) welded into robust steel frames (e.g., 32mm-42mm OD, 1.5-2.0mm wall thickness) creates a high strength-to-weight ratio. This design ensures the panels can withstand significant lateral loads from wind, impacts, or crowd pressure without deformation or failure, complying with AS 4687-2007 structural stability requirements.

- Optimized Installation Efficiency: Featuring a modular design with standardized panel dimensions and compatible heavy-duty bases (plastic or concrete) and clamps, our systems facilitate rapid and straightforward installation and dismantling. This minimizes labor costs and project downtime, a critical factor for dynamic construction sites and time-sensitive events.

- Enhanced Security Features: The tightly woven mesh patterns (e.g., 60x150mm) are designed to be anti-climb, deterring unauthorized access more effectively than wider mesh alternatives. The secure connection systems between panels further reduce vulnerabilities.

- Environmental and Economic Sustainability: The extended service life and high reusability of our hot-dip galvanized fences reduce the need for frequent replacements, contributing to lower material consumption and waste. This translates into significant long-term cost savings and a reduced environmental footprint for our clients.

Performance Comparison: Hot-Dip Galvanized vs. Other Finishes

| Feature | Hot-Dip Galvanized (Our Product) | Electro-Galvanized | Painted/Powder Coated |

|---|---|---|---|

| Zinc Coating Thickness | ≥42 µm (post-welding) | 8-15 µm | N/A (no zinc coating) |

| Corrosion Resistance | Excellent (10-15+ years) | Fair (2-5 years) | Poor (1-3 years, prone to chipping) |

| Abrasion Resistance | High | Medium | Low (paint chips easily) |

| Cost-Effectiveness (Long Term) | Very High | Medium | Low (due to frequent replacement) |

| Weld Protection | Complete (galvanized after welding) | Minimal (pre-galvanized, welds exposed) | Dependent on post-weld painting, often weak point |

Vendor Comparison and Customised Solutions

In the competitive landscape of temporary fencing, selecting the right vendor for your Australia Temporary Fence needs is paramount. Differentiators extend beyond mere pricing to encompass product quality, engineering expertise, supply chain reliability, and the ability to provide bespoke solutions.

Key Vendor Differentiators:

- Adherence to Australian Standards: A reputable vendor will demonstrate strict compliance with local regulations like AS 4687-2007. This ensures not only safety but also avoids potential project delays and penalties.

- Material Quality & Galvanization: Scrutinize the type and thickness of galvanization (hot-dip post-welding is superior). Inferior galvanization leads to premature corrosion and higher lifecycle costs.

- Manufacturing Expertise & QC: Vendors with ISO 9001 certification and robust internal quality control processes generally offer more consistent, defect-free products.

- Logistics and Lead Times: The ability to fulfill large orders promptly and manage efficient logistics is critical for project timelines. Evaluate average lead times and freight capabilities.

- After-Sales Support & Warranty: A comprehensive warranty and responsive customer support for technical queries or replacement parts indicate a vendor's commitment to long-term client relationships.

Customized Solutions for Australia Temporary Fence Systems:

While standard Australia Temporary Fence panels meet a vast array of requirements, many projects necessitate tailored solutions to address unique site constraints, aesthetic preferences, or enhanced security demands. Our capabilities extend to providing a range of customizable options:

- Non-Standard Panel Dimensions: For specific height or width requirements, we can fabricate panels to bespoke measurements, ensuring a seamless fit for challenging perimeters.

- Integrated Gate Systems: Custom-designed pedestrian, single-vehicle, or double-vehicle swing gates, complete with heavy-duty hinges and locking mechanisms, integrated seamlessly into the temporary fence line.

- Enhanced Security Features: Options include razor wire or barbed wire extensions for high-security applications, specialized anti-climb mesh variations, or deeper embedded posts for semi-permanent installations.

- Branding and Aesthetics: Integration of company branding or specific color coatings (e.g., powder coating over galvanization) for a professional appearance, often required for public-facing projects or events.

- Specialized Bases and Bracing: Development of custom base plates or wind bracing solutions for sites with challenging ground conditions (e.g., uneven terrain, high wind zones) or where specific stability requirements exceed standard provisions.

Our engineering team collaborates closely with clients from conceptualization through to deployment, ensuring that customized solutions not only meet functional requirements but also adhere to all relevant safety and quality standards.

Figure 3: Custom Australia Temporary Fence configuration with pedestrian gate and branding.

Ensuring Quality and Trust: Our Commitment

At the core of our operations is an unwavering commitment to Google's (Expertise, Experience, Authoritativeness, Trustworthiness) standards, ensuring our clients receive not just products, but reliable, expert-backed solutions.

Expertise:

Our team comprises seasoned engineers and metallurgical specialists with deep expertise in steel fabrication, galvanization processes, and temporary fencing design. This expertise is continually updated through ongoing research into material science, advanced manufacturing techniques, and evolving industry standards (e.g., AS 4687-2007). We leverage this technical proficiency to design and produce Australia Temporary Fence systems that are not only robust but also optimized for specific environmental and application challenges. Our consultative approach ensures clients benefit from this knowledge in selecting or customizing the ideal fencing solution.

Experience:

With over two decades in the wire mesh and fencing industry, we have accumulated extensive practical experience in delivering projects of varying scales and complexities across Australia and globally. Our portfolio includes successful deployments for major infrastructure developments, large-scale public events, and critical industrial sites. This hands-on experience, coupled with invaluable customer feedback, allows us to refine our product designs and service delivery continually, ensuring our Australia Temporary Fence solutions are tried, tested, and proven in real-world scenarios.

Authoritativeness:

- Certifications: We operate under ISO 9001:2015 certified quality management systems, affirming our commitment to consistent quality across all manufacturing and supply chain processes. Our products rigorously comply with Australian Standards, including AS 4687-2007 for temporary fencing and AS/NZS 4680 for hot-dip galvanization.

- Industry Partnerships: We maintain strong, long-standing relationships with leading construction companies, event organizers, and government agencies, attesting to our reliability and product performance.

- Test Data & Analytics: Our products undergo continuous testing for tensile strength, weld integrity, and galvanization thickness. Performance data and analysis are available upon request, providing transparent insights into our product capabilities.

Trustworthiness:

Our commitment to trustworthiness is reflected in our transparent business practices and robust customer support infrastructure.

Frequently Asked Questions (FAQ):

- Q: How does your temporary fence withstand strong winds?

- A: Our Australia Temporary Fence panels are designed with robust frames and anti-climb mesh, anchored by heavy-duty bases (plastic or concrete) which provide significant stability. For extreme wind conditions, additional bracing and ground anchors are recommended and can be supplied.

- Q: What is the expected service life of your hot-dip galvanized fences?

- A: With proper care and maintenance, our hot-dip galvanized fences are engineered for a service life of 10-15 years or more, significantly outperforming other finishes in Australian conditions.

- Q: Are your fences compliant with Australian safety standards?

- A: Absolutely. All our Australia Temporary Fence products are manufactured and tested to meet or exceed the requirements of AS 4687-2007 (Temporary Fencing and Hoardings).

Lead Time & Fulfillment:

We maintain efficient production schedules and robust logistics networks to ensure timely delivery. Standard orders for Australia Temporary Fence panels typically have a lead time of 2-4 weeks, while custom solutions may require 4-6 weeks depending on complexity. Our logistics team works diligently to arrange efficient and cost-effective freight to your specified location across Australia.

Warranty Commitments:

We stand behind the quality of our products with a comprehensive warranty against defects in material and workmanship. Specific warranty periods are provided with each quotation, reflecting our confidence in the durability and performance of our temporary fencing solutions.

Customer Support:

Our dedicated customer support team is available to assist with inquiries, technical specifications, order tracking, and after-sales service. From initial consultation to post-delivery support, we ensure a seamless and responsive experience for our clients.

Figure 4: A stack of Australia Temporary Fence panels, ready for dispatch.

Conclusion

The demand for high-quality, durable, and compliant temporary fencing solutions in Australia continues to grow, driven by vigorous activity in the construction, events, and infrastructure sectors. Our Australia Temporary Fence systems are meticulously engineered and manufactured to not only meet but exceed the stringent requirements of these dynamic industries. By focusing on superior materials, advanced hot-dip galvanization processes, and strict adherence to Australian Standards, we deliver fencing solutions that offer exceptional corrosion resistance, structural integrity, ease of installation, and a prolonged service life. Our commitment to principles – demonstrating deep expertise, extensive experience, undisputed authoritativeness, and transparent trustworthiness – ensures that our clients receive not just products, but comprehensive, reliable, and cost-effective security and demarcation solutions tailored to their specific project needs. Partnering with us means investing in long-term performance, safety, and peace of mind for your operational requirements across Australia.

References

- 1. Standards Australia. AS 4687-2007 Temporary fencing and hoardings. SAI Global.

- 2. Standards Australia. AS/NZS 4680:2006 Hot-dip galvanized (zinc) coatings on fabricated ferrous articles. SAI Global.

- 3. International Organization for Standardization. ISO 9001:2015 Quality management systems – Requirements.

- 4. Galvanizers Association of Australia. The Performance of Zinc Coatings.

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.