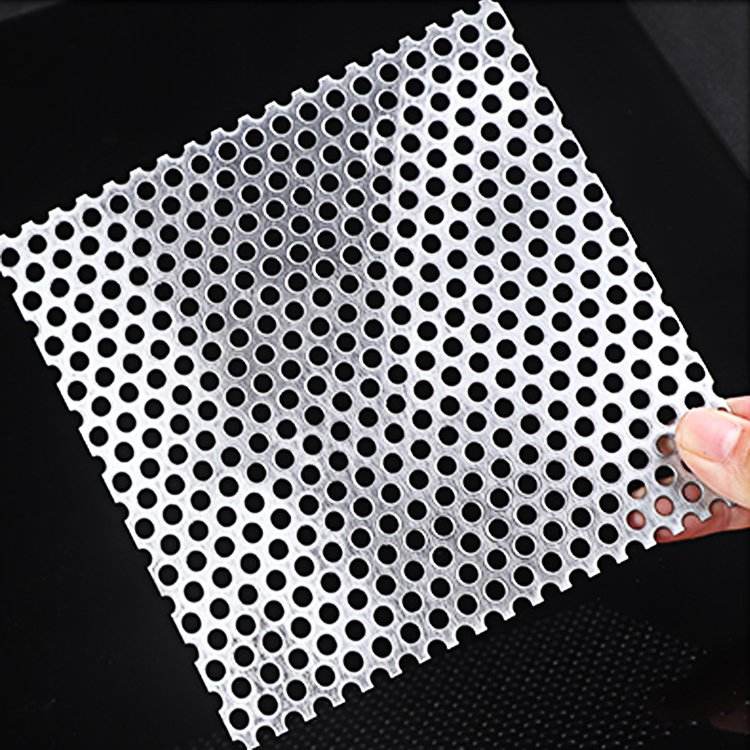

3D Galvanized Steel Perforated Metal Sheets are engineered to meet the demands of modern industrial and architectural applications. These sheets combine the strength of galvanized steel with precision-engineered perforations, offering a blend of durability, functionality, and aesthetic appeal. Whether used in fencing, filtration systems, or structural components, these products are designed to deliver long-term performance and adaptability. This article explores the technical specifications, applications, and advantages of 3D Galvanized Steel Perforated Metal Sheets, alongside insights into the company behind this innovation, AnPing Zhongtai Expanded Metal Mesh Co., Ltd.

Understanding the Structure of Perforated Holes

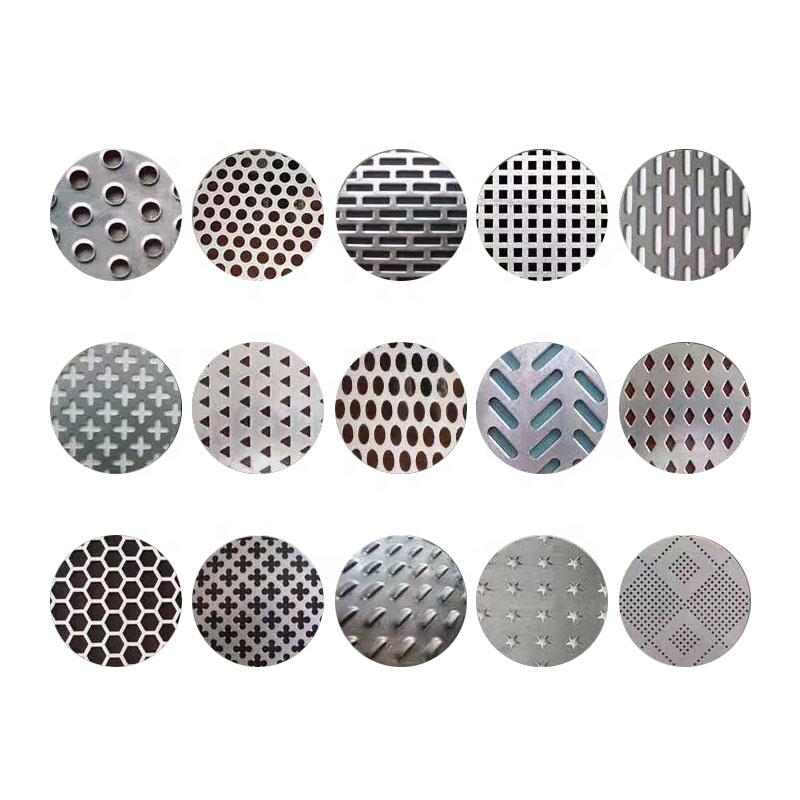

The unique design of 3D Galvanized Steel Perforated Metal Sheets is defined by their hole structure, which is created through a multi-step production process. The holes consist of three key zones:

- Zone of Dents: This area forms during the initial stages of perforation, where the material is compressed to create the hole's base.

- Cutting Zone: The material is precisely cut to shape the hole, ensuring uniformity and accuracy.

- Extraction Area: This section allows for the removal of excess material, leaving behind the final perforated pattern.

These zones work in harmony to create a robust structure that maintains the integrity of the sheet while enabling airflow, light transmission, and other functional properties. The 3D Galvanized Steel Perforated Metal Sheet can also be customized with full perforation fields or unperforated margins, depending on specific requirements. For tailored solutions, customers can consult with the manufacturer to design sheets based on their blueprints.

Technical Specifications and Material Options

The 3D Galvanized Steel Perforated Metal Sheet is available in a range of materials and dimensions to suit diverse applications. Key technical parameters include:

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers. |

| Thickness | Up to 18 mm |

| Width | Up to 2,000 mm |

| Length | Up to 6,000 mm |

| Perforation Options | Standard unperforated margins; custom perforation based on customer drawings; full perforation fields available upon consultation. |

| Additional Processing | Single straightening, cutting to size, packing on pallets, bending, rolling, pressing, welding, powder coating, and oil cleaning. |

The versatility of the 3D Galvanized Steel Perforated Metal Sheet is further enhanced by its compatibility with various materials. For instance, stainless steel options provide corrosion resistance, while aluminum and brass offer lightweight and aesthetic appeal. The sheets can also be produced in coils, with a maximum width of 1,600 mm, enabling flexible manufacturing processes. However, certain perforation types may require unperforated technological margins to ensure structural stability.

Applications Across Industries

The 3D Galvanized Steel Perforated Metal Sheet is a versatile solution for a wide range of industries. Its applications include:

- Chemical Machinery: Used in filtration systems and ventilation units to ensure efficient airflow and material separation.

- Pharmaceutical Equipment: Provides hygienic surfaces and precise filtration for drug manufacturing processes.

- Food and Beverage Machines: Offers durable, easy-to-clean surfaces for processing and packaging equipment.

- Refrigeration Equipment: Enhances heat exchange efficiency in central air conditioning systems.

- Acoustic Applications: Utilized in silencing equipment and speakers to control sound transmission.

- Construction and Fencing: Ideal for fencing and structural components due to its strength and durability.

For example, in the food and beverage industry, the 3D Galvanized Steel Perforated Metal Sheet is used to create hygienic filtration systems that prevent contamination while maintaining product quality. Similarly, in acoustic engineering, the sheet’s perforation patterns are optimized to absorb or reflect sound, making it a critical component in soundproofing and noise reduction solutions.

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd

AnPing Zhongtai Expanded Metal Mesh Co., Ltd is a leading manufacturer of perforated metal sheets and expanded metal mesh. With years of experience in the industry, the company specializes in producing high-quality, customized metal products tailored to meet global standards. Their expertise in 3D Galvanized Steel Perforated Metal Sheets is backed by advanced production technologies and a commitment to innovation.

The company’s state-of-the-art facilities are equipped with automated cutting systems, such as the 1.ll-round 360 production line, which enables automatic tube feeding, cutting, and transmission. This technology ensures precision and efficiency, reducing waste and improving productivity. Additionally, KASRY Nesting programming systems are used to streamline the design process, allowing for complex patterns and shapes to be created with ease.

AnPing Zhongtai Expanded Metal Mesh Co., Ltd also offers a range of value-added services, including bending, welding, and powder coating, to deliver ready-made components that meet customer specifications. Their dedication to quality is reflected in their adherence to international standards, ensuring that every product is reliable and long-lasting.

Advantages of 3D Galvanized Steel Perforated Metal Sheets

The 3D Galvanized Steel Perforated Metal Sheet offers several advantages that make it a preferred choice for industrial and architectural applications:

- Durability: Galvanized steel provides excellent resistance to corrosion, ensuring the sheet’s longevity even in harsh environments.

- Customization: The ability to create custom perforation patterns and dimensions allows for tailored solutions to specific needs.

- Strength and Stability: The 3D structure enhances the sheet’s load-bearing capacity, making it suitable for structural applications.

- Cost-Effectiveness: The sheets reduce material waste and require minimal maintenance, lowering long-term costs.

- Environmental Benefits: The use of recyclable materials and energy-efficient production processes aligns with sustainable manufacturing practices.

These advantages make the 3D Galvanized Steel Perforated Metal Sheet an ideal choice for fencing and other applications where strength, durability, and adaptability are critical. For instance, in fencing projects, the sheet’s perforation patterns allow for aesthetic design while maintaining security and durability.

Conclusion

The 3D Galvanized Steel Perforated Metal Sheet represents a significant advancement in metal fabrication, combining strength, versatility, and precision. With its wide range of applications and customizable features, it is a valuable asset for industries such as construction, manufacturing, and engineering. AnPing Zhongtai Expanded Metal Mesh Co., Ltd continues to lead the way in innovation, delivering high-quality products that meet the evolving needs of the market.

For more information about the 3D Galvanized Steel Perforated Metal Sheet or to explore the company’s full range of products, visit the [product page](https://www.ztwiremesh.com/3d-galvanized-steel-material-perf-bp.html) or the [company website](https://www.ztwiremesh.com/).

References

1. National Institute of Standards and Technology (NIST). (n.d.). Standards for Metal Fabrication. Retrieved from https://www.nist.gov/

2. NIST. (2023). ASTM A653: Standard Specification for Zinc-Coated (Galvanized) Steel Sheet. Retrieved from https://www.nist.gov/

3. NIST. (2022). Material Testing and Quality Assurance in Industrial Applications. Retrieved from https://www.nist.gov/

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.