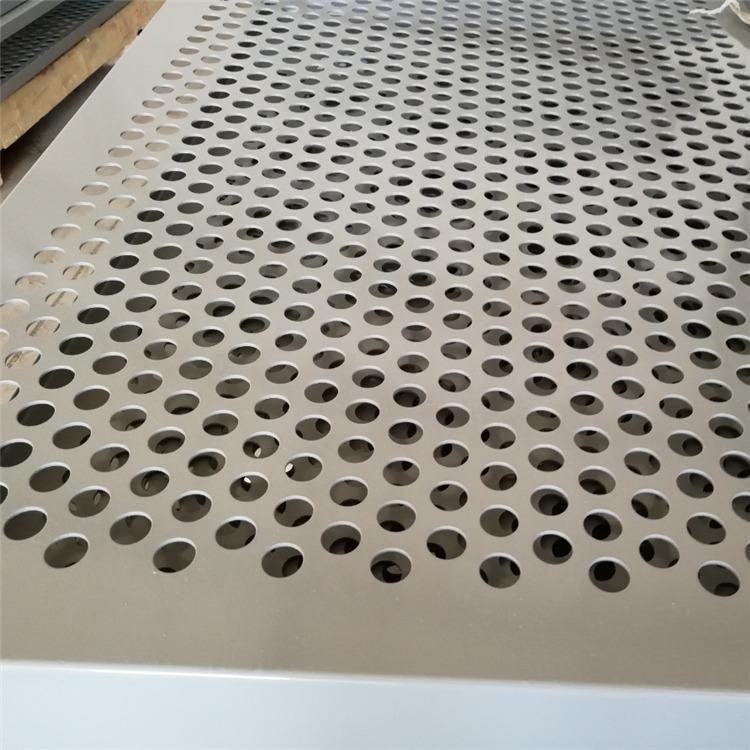

The 3D Galvanized Steel Perforated Sheet is a versatile and durable material designed for industrial and architectural applications. Engineered with precision, this perforated metal sheet combines structural integrity with functional adaptability, making it an ideal choice for fencing, filtration systems, and more. Manufactured by AnPing Zhongtai Expanded Metal Mesh Co., Ltd, the product exemplifies advanced metallurgical techniques and customization capabilities.

Key Features of 3D Galvanized Steel Perforated Sheet

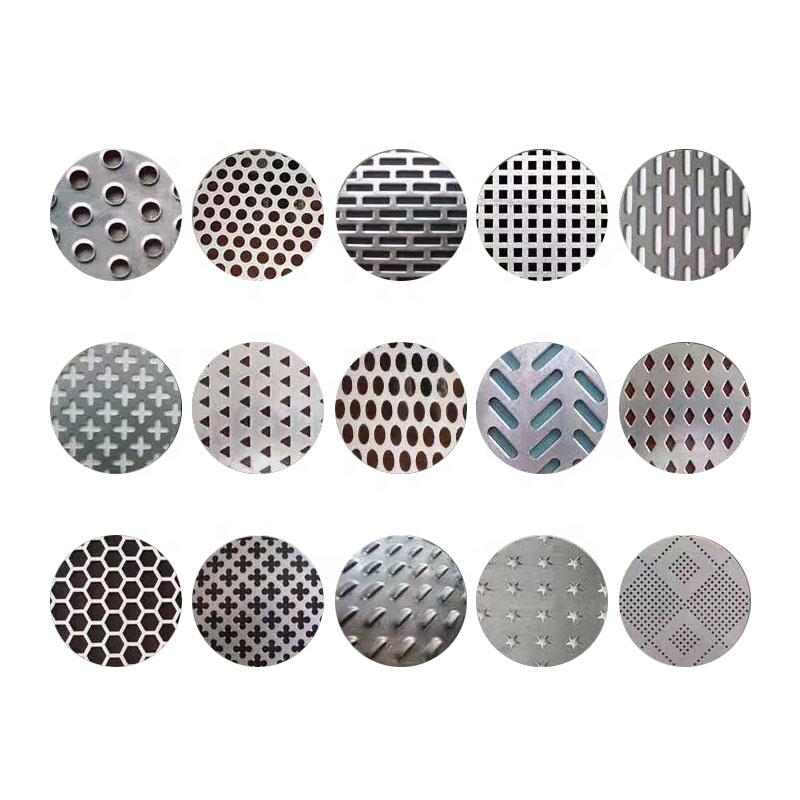

The 3D Galvanized Steel Perforated Sheet is distinguished by its unique hole structure, which is critical to its performance. The perforation process involves three distinct zones: the Zone of Dents, Cutting Zone, and Extraction Area. These zones are formed during production to ensure optimal strength and precision. The Zone of Dents creates the initial indentation, while the Cutting Zone defines the shape and size of the holes. Finally, the Extraction Area ensures the material maintains its structural integrity after perforation.

Standard sheets are produced with unperforated margins along the transverse and longitudinal edges. However, the product offers flexibility for custom designs based on customer specifications. For instance, full perforation fields or specialized patterns can be achieved after consultation. This adaptability makes the 3D Galvanized Steel Perforated Sheet suitable for a wide range of applications, from industrial machinery to decorative elements.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers |

| Thickness | Up to 18 mm |

| Width | Up to 2,000 mm |

| Length | Up to 6,000 mm |

| Perforation Options | Custom patterns, full perforation fields (with consultation), unperforated margins |

| Standard Processes | Single straightening, cutting to size, packing on pallets |

| Additional Services | Bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, oil cleaning |

The 3D Galvanized Steel Perforated Sheet is designed to meet rigorous industrial standards. Its versatility in material selection allows it to withstand harsh environments, while its dimensional flexibility ensures compatibility with diverse manufacturing requirements.

Applications Across Industries

The 3D Galvanized Steel Perforated Sheet is widely used in multiple sectors due to its durability and adaptability. In the chemical machinery industry, it serves as a filtration component, ensuring efficient separation of materials. In pharmaceutical equipment, the sheet’s resistance to corrosion makes it ideal for sterilization and containment systems. For food and beverage machines, its non-porous surface simplifies cleaning and compliance with hygiene standards.

Other applications include dry-cleaning machines, where the sheet’s strength supports heavy-duty operations, and refrigeration equipment, where it enhances airflow and insulation. The product is also used in speakers for sound diffusion, papermaking for pulp filtration, and hydraulic fittings for pressure resistance. Its ability to be customized further expands its utility in crafts and silencing equipment.

Advantages of 3D Galvanized Steel Perforated Sheet

The 3D Galvanized Steel Perforated Sheet offers several advantages that make it a preferred choice for manufacturers and engineers. Its 3D galvanization process provides enhanced corrosion resistance, extending the material’s lifespan in outdoor and industrial settings. The perforation design also allows for optimal airflow and light transmission, which is critical in applications like ventilation systems and architectural facades.

Additionally, the sheet’s customization capabilities enable it to meet specific project requirements. For example, trapezoidal shaping and powder coating can be applied to improve aesthetics and functionality. The standard straightening process ensures the material remains flat and stable, reducing the need for additional finishing work.

Another key advantage is the cost-effectiveness of the product. By offering ready-made components through additional processing services, AnPing Zhongtai Expanded Metal Mesh Co., Ltd minimizes the need for on-site modifications, saving time and resources for customers.

About AnPing Zhongtai Expanded Metal Mesh Co., Ltd

AnPing Zhongtai Expanded Metal Mesh Co., Ltd is a leading manufacturer of perforated metal sheets and expanded metal mesh. With decades of experience in the industry, the company specializes in producing high-quality metal products tailored to diverse applications. Their state-of-the-art facilities and advanced production techniques ensure precision and consistency in every batch.

The company’s commitment to innovation is evident in its ability to customize perforation patterns and process materials according to customer specifications. Whether it’s a standard 3D Galvanized Steel Perforated Sheet or a specialized design, AnPing Zhongtai delivers solutions that meet the highest industry standards. Their services include cutting, bending, welding, and powder coating, making them a one-stop partner for industrial and architectural projects.

Conclusion

The 3D Galvanized Steel Perforated Sheet is a testament to the synergy between advanced manufacturing and practical design. Its robust construction, customizable features, and wide range of applications make it an indispensable material for modern industries. By partnering with AnPing Zhongtai Expanded Metal Mesh Co., Ltd, customers gain access to a reliable supplier that prioritizes quality, innovation, and customer satisfaction.

References

[1] National Institute of Standards and Technology (NIST). "Driving Innovation." https://www.nist.gov/. Accessed September 2025.

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.