In the realm of industrial and construction materials, 3D Galvanized Steel Perforated Metal Sheets have emerged as a transformative solution, blending advanced engineering with practical utility. Designed for fencing applications, these sheets combine structural integrity with customizable design, making them a preferred choice across diverse industries. This article delves into the features, technical specifications, application scenarios, and the expertise of AnPing Zhongtai Expanded Metal Mesh Co., Ltd, a leading manufacturer of perforated metal products.

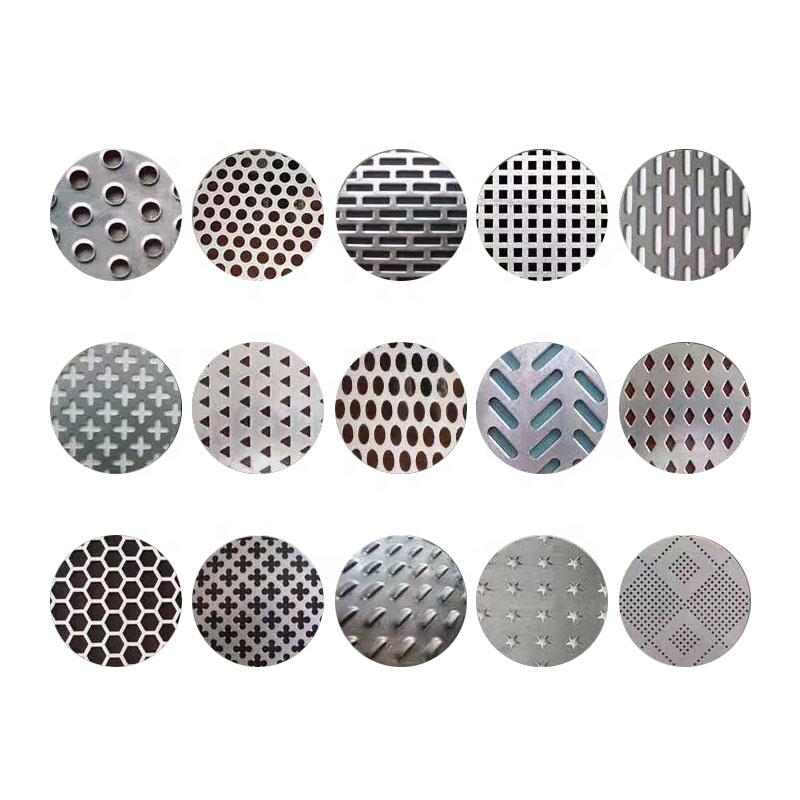

Core Features of 3D Galvanized Steel Perforated Metal Sheets

The 3D Galvanized Steel Perforated Metal Sheet is engineered with a unique hole structure that enhances its functional versatility. During production, the sheet undergoes a three-phase process:

- Zone of Dents: This area forms the initial indentation, creating a textured surface that improves grip and resistance to wear.

- Cutting Zone: The precise cutting mechanism ensures uniform hole dimensions, maintaining structural consistency.

- Extraction Area: This phase involves the removal of material, allowing for the creation of intricate patterns while preserving the sheet’s strength.

Additionally, the sheets are available with unperforated margins along the transverse and longitudinal edges, ensuring stability during installation. For specialized requirements, customers can opt for custom designs or full perforation fields, subject to consultation with the manufacturer. Post-perforation, the sheets are straightened to eliminate warping, and further processing options include bending, welding, and powder coating, enabling the production of ready-made components.

Image: Read More About perforated metal sheet

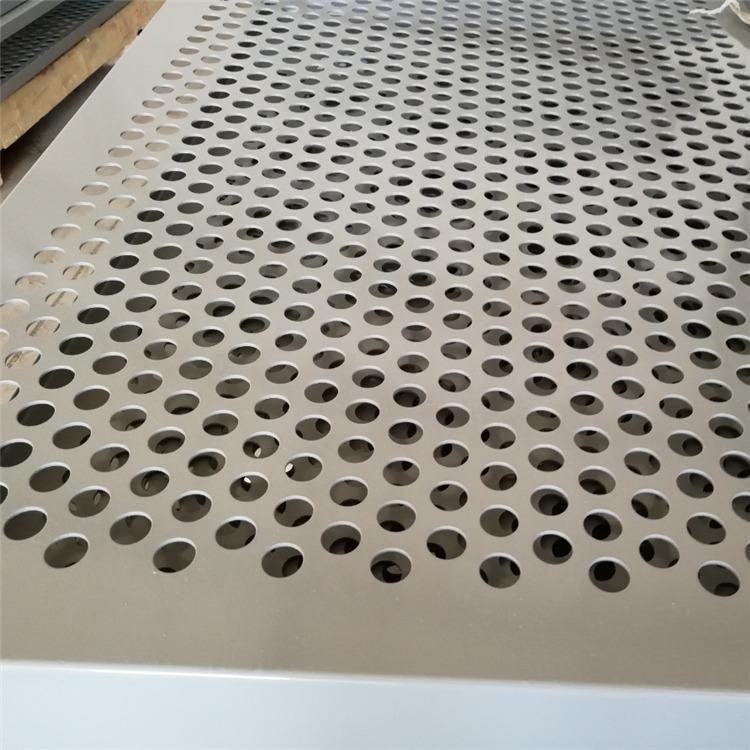

Technical Specifications and Material Options

The 3D Galvanized Steel Perforated Metal Sheet is available in a wide range of materials, including ordinary steel, abrasion-resistant steel, heat-resistant alloys, stainless steel, and corrosion-resistant metals like aluminum and copper. This versatility ensures that the product meets the demands of various environments, from industrial settings to outdoor applications.

| Parameter | Details |

|---|---|

| Material | Ordinary steel, stainless steel, aluminum, copper, brass, bronze, plastics, rubbers |

| Thickness | Up to 18 mm |

| Width | Up to 2,000 mm |

| Length | Up to 6,000 mm |

| Standard Operations | Single straightening, cutting to size, pallet packing |

| Additional Services | Bending, rolling, trapezoidal shaping, welding, powder coating |

For coil perforation, the maximum coil width is 1,600 mm. However, certain perforation types may require unperforated margins to maintain structural integrity. These specifications highlight the product’s adaptability to both standard and custom manufacturing needs.

Image: Read More About perforated metal sheet

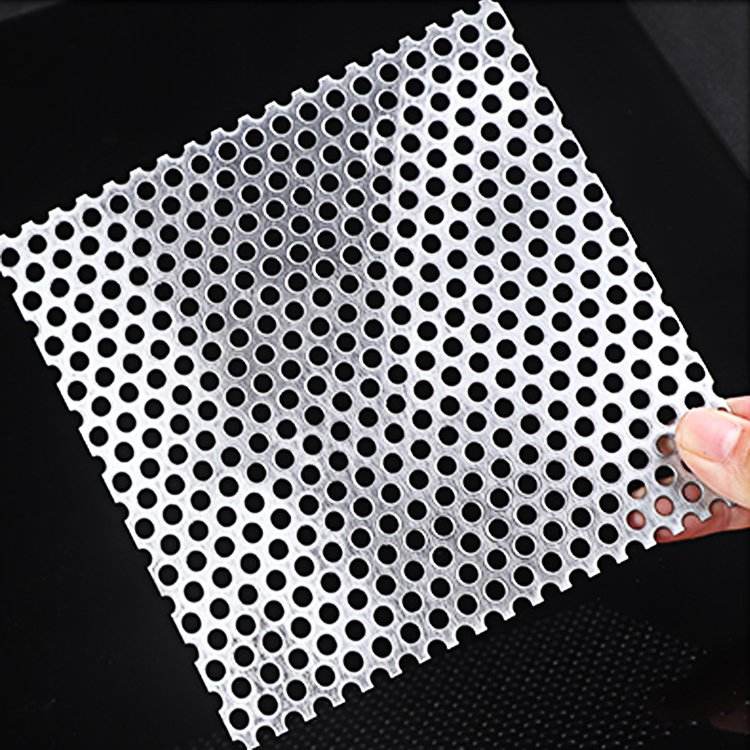

Applications Across Industries

The 3D Galvanized Steel Perforated Metal Sheet is a cornerstone in numerous sectors due to its durability and adaptability. Key applications include:

- Chemical Machinery: Used in filtration systems and containment units, where resistance to corrosion and chemical exposure is critical.

- Pharmaceutical Equipment: Ensures hygienic environments with easy-to-clean surfaces and precise filtration capabilities.

- Food and Beverage Machines: Ideal for conveyor belts and separators, offering robust performance in high-moisture settings.

- Refrigeration Equipment: Enhances airflow in central air conditioning systems, improving efficiency.

- Acoustic Applications: Integrated into silencing equipment and speaker enclosures to control noise levels.

- Construction and Fencing: Provides a secure, aesthetically pleasing barrier for industrial and residential properties.

As noted by the National Institute of Standards and Technology (NIST), the precision in manufacturing processes like those used for perforated metal sheets is essential for meeting industry standards. "Accurate measurements and consistent quality are vital for ensuring the reliability of materials in critical applications," states NIST’s Standards and Measurements division. This aligns with the rigorous specifications of the 3D Galvanized Steel Perforated Metal Sheet, which undergoes meticulous production to meet such benchmarks.

Image: Read More About perforated metal sheet

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd

Founded with a commitment to innovation and quality, AnPing Zhongtai Expanded Metal Mesh Co., Ltd has established itself as a leader in the production of 3D Galvanized Steel Perforated Metal Sheets. The company leverages advanced manufacturing technologies, including the KASRY Nesting programming system, to optimize production efficiency. This software, compatible with AutoCAD, allows for intuitive design and precise execution of custom perforation patterns.

AnPing Zhongtai’s capabilities extend beyond standard production. The company offers a comprehensive range of services, including automated tube feeding, cutting, and transmission operations, as highlighted in their product documentation. These processes ensure that clients receive ready-to-install components, reducing the need for additional machining.

The company’s dedication to quality is reflected in its adherence to international standards. By integrating NIST-endorsed measurement practices, AnPing Zhongtai ensures that its products meet the exacting demands of global markets. As emphasized by NIST, "Precision in manufacturing is not just a technical requirement—it is a foundational element of innovation and safety" (NIST Standards and Measurements).

Conclusion

The 3D Galvanized Steel Perforated Metal Sheet exemplifies the synergy between engineering excellence and practical application. With its robust design, customizable features, and wide-ranging applications, this product is a testament to the advancements in metal fabrication. AnPing Zhongtai Expanded Metal Mesh Co., Ltd continues to lead the industry by combining cutting-edge technology with a customer-centric approach, ensuring that their offerings meet the evolving needs of modern industries.

References

-

Understanding Steel Grating Price Per Square Meter: Global Insights & Practical Guide

NewsNov.25,2025

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.