Perforated metal sheets have become an essential component in modern industrial and architectural applications, offering a unique combination of strength, durability, and design flexibility. Among these, 3D galvanized steel perforated metal sheets stand out for their advanced structural properties and versatility. This article provides an in-depth analysis of the product's features, technical specifications, applications, and the company behind it, while incorporating authoritative references from the National Institute of Standards and Technology (NIST).

Product Features and Structural Design

The 3D galvanized steel perforated metal sheet is engineered with a unique three-zone structure that enhances its mechanical performance and adaptability to various industrial needs. During the production process, the sheet undergoes three critical stages:

- Zone of Dents: This area is designed to absorb impact and distribute stress evenly across the sheet, reducing the risk of structural failure.

- Cutting Zone: Precision cutting ensures accurate hole patterns, which are essential for applications requiring specific airflow, filtration, or aesthetic designs.

- Extraction Area: This zone facilitates the removal of excess material, ensuring a clean and consistent finish without compromising the sheet's integrity.

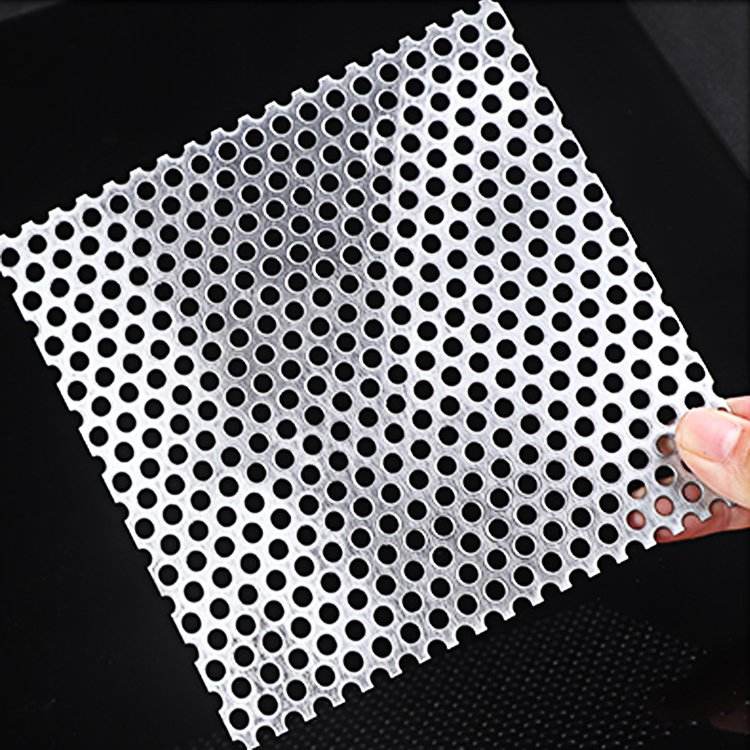

Additionally, the sheets are typically produced with unperforated margins in both transverse and longitudinal directions. However, customization is possible through customer drawings or full perforation fields, provided the client consults with the manufacturer. This flexibility allows the product to meet specialized requirements in industries ranging from construction to advanced manufacturing.

Technical Specifications

The technical parameters of the 3D galvanized steel perforated metal sheet are designed to accommodate a wide range of applications. Key specifications include:

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers. |

| Format | Thickness up to 18 mm, width up to 2,000 mm, length up to 6,000 mm. Coils can be perforated with a width up to 1,600 mm. |

| Standard Operations | Single straightening, cutting to size, and packing on pallets. |

| Additional Operations | Bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, and oil cleaning. |

These specifications highlight the product's adaptability. For instance, the ability to handle materials like stainless steel and acid-resistant alloys makes it suitable for harsh environments, such as chemical processing plants or coastal infrastructure. The dimensional flexibility ensures compatibility with both small-scale projects and large industrial systems.

Applications in Diverse Industries

The versatility of 3D galvanized steel perforated metal sheets is evident in their wide range of applications. According to the NIST, "precision engineering and material innovation are critical for advancing industrial efficiency and sustainability." This principle aligns with the use of perforated metal sheets in the following sectors:

- Chemical Machinery: The sheets are used in filtration systems and reaction chambers, where their corrosion resistance and structural integrity are vital.

- Pharmaceutical Equipment: Their ability to maintain sterility and resist chemical exposure makes them ideal for cleanroom environments.

- Food and Beverage Machines: The sheets are employed in conveyors and separators, ensuring compliance with hygiene standards.

- Refrigeration Equipment: Their thermal conductivity and durability support efficient heat exchange in central air conditioning systems.

- Acoustic Applications: The perforations help in sound absorption, making them suitable for speakers and silencing equipment.

Moreover, the product's adaptability extends to creative industries, such as crafts and papermaking, where its aesthetic appeal and functional properties are leveraged for unique designs. As noted by NIST, "innovative materials like perforated metal sheets are reshaping traditional manufacturing processes" (NIST).

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd.

Founded in Anping County, Hebei Province, AnPing Zhongtai Expanded Metal Mesh Co., Ltd. has established itself as a leading manufacturer of perforated metal products. The company specializes in producing high-quality, custom-engineered metal sheets that cater to both domestic and international markets. With a commitment to innovation and precision, AnPing Zhongtai has become a trusted name in the industry.

According to the NIST, "companies that prioritize research and development (R&D) are better positioned to meet evolving industry demands." AnPing Zhongtai exemplifies this by continuously refining its production processes. For example, the company utilizes advanced machinery, such as the 1.ll-round 360 production line cutting group, which enables automatic tube feeding, cutting, and transmission operations. This technology enhances efficiency and reduces human error, ensuring consistent quality.

The company also employs the KASRY Nesting programming system, which integrates with AutoCAD for intuitive design and programming. This system streamlines the production workflow, allowing for faster turnaround times and cost savings for clients. As highlighted by NIST, "automation and digital tools are transforming manufacturing, enabling companies to achieve higher precision and scalability" (NIST).

Advantages of 3D Galvanized Steel Perforated Metal Sheets

Several factors contribute to the popularity of 3D galvanized steel perforated metal sheets:

- Enhanced Durability: The galvanized coating provides a protective layer against corrosion, making the sheets suitable for outdoor and industrial environments.

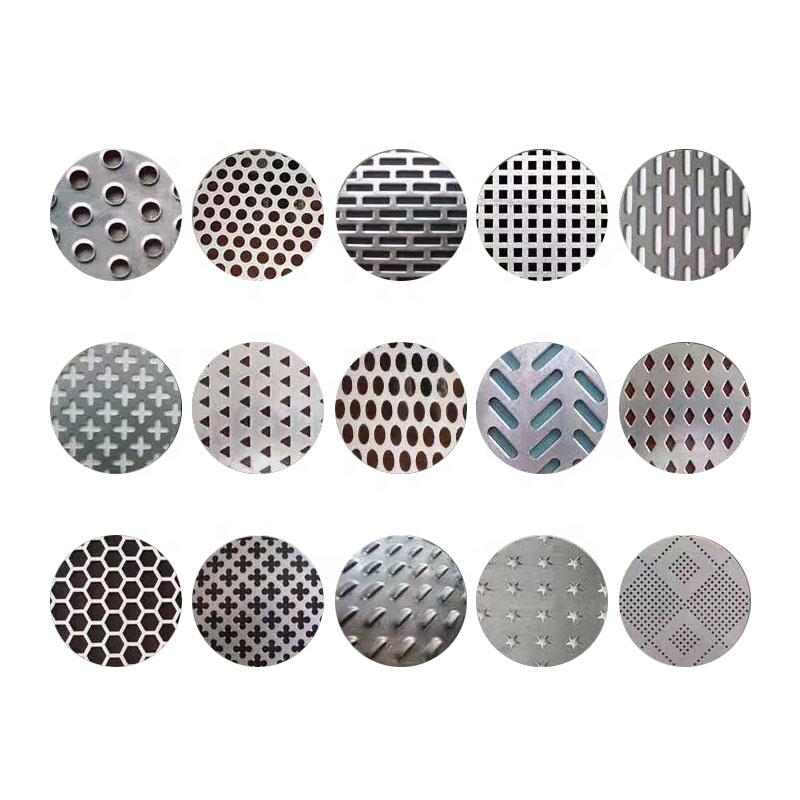

- Design Flexibility: Customizable hole patterns and sizes allow for tailored solutions in architectural and functional applications.

- Cost-Effectiveness: The sheets' longevity and low maintenance requirements reduce long-term costs compared to alternative materials.

- Environmental Benefits: The ability to recycle steel and the energy-efficient production processes align with sustainable manufacturing practices.

These advantages are further supported by NIST's research on material science, which emphasizes the importance of "durable and adaptable materials in modern engineering" (NIST).

Conclusion

The 3D galvanized steel perforated metal sheet represents a significant advancement in material technology, offering a balance of strength, versatility, and aesthetic appeal. Its applications span across multiple industries, from chemical processing to architectural design, making it a valuable asset for manufacturers and engineers. AnPing Zhongtai Expanded Metal Mesh Co., Ltd. has demonstrated its commitment to innovation and quality, ensuring that its products meet the highest standards of performance and reliability.

For more information about the product, visit the product page or explore the company website.

References

National Institute of Standards and Technology (NIST) (2025). "Driving Innovation: NIST's Role in Advancing Technology." Retrieved from https://www.nist.gov/.

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.