Introduction

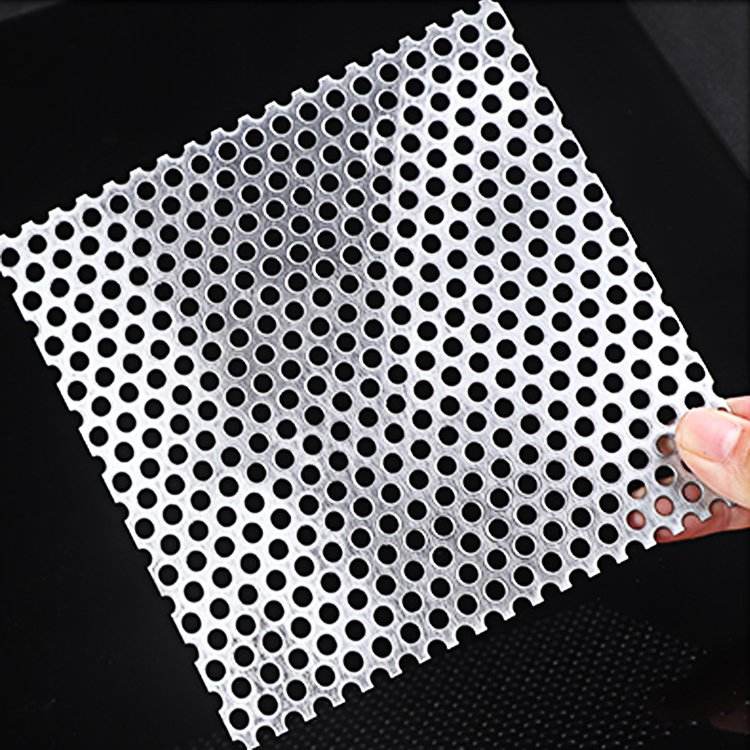

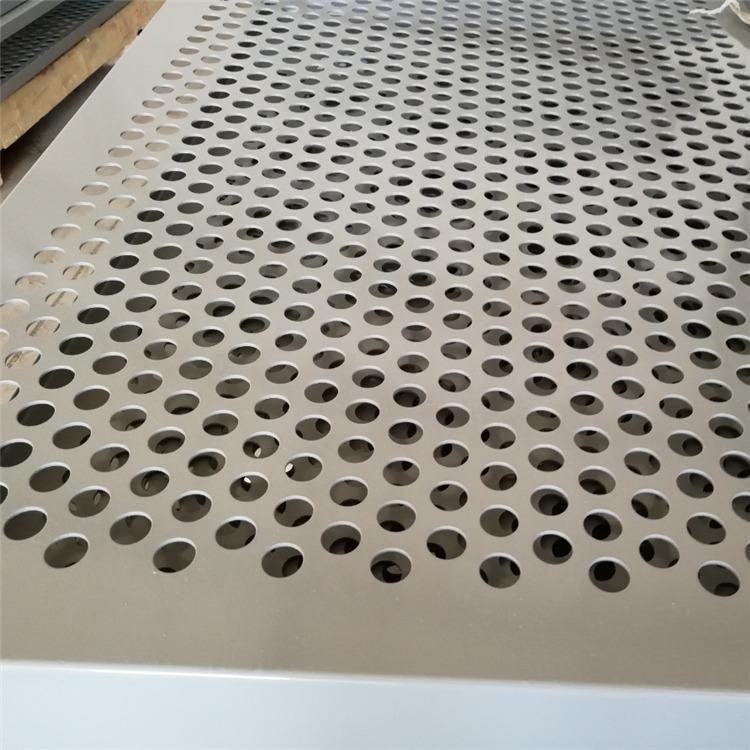

The 3D galvanized steel perforated metal sheet represents a breakthrough in industrial material design, combining durability, precision engineering, and adaptability across diverse sectors. This article delves into the product's structure, technical parameters, applications, and the company behind it, AnPing Zhongtai Expanded Metal Mesh Co., Ltd, while emphasizing its alignment with industry standards.

Product Structure and Manufacturing Process

The 3D galvanized steel perforated metal sheet is engineered through a meticulous production process that creates a unique three-part hole structure:

- Zone of Dents: This area forms during the initial stamping phase, creating the foundational shape of the perforations.

- cutting Zone: The material is precisely cut to achieve the desired pattern and dimensions.

- Extraction Area: This stage involves removing the excess material, leaving behind the structured perforations.

Standard sheets typically feature unperforated margins along the transverse and longitudinal edges. However, custom designs are possible through collaboration with the manufacturer, allowing for full perforation fields or tailored specifications. After perforation, the sheets undergo straightening, with additional processing options such as bending, welding, and powder coating to meet specific customer needs.

Technical Specifications

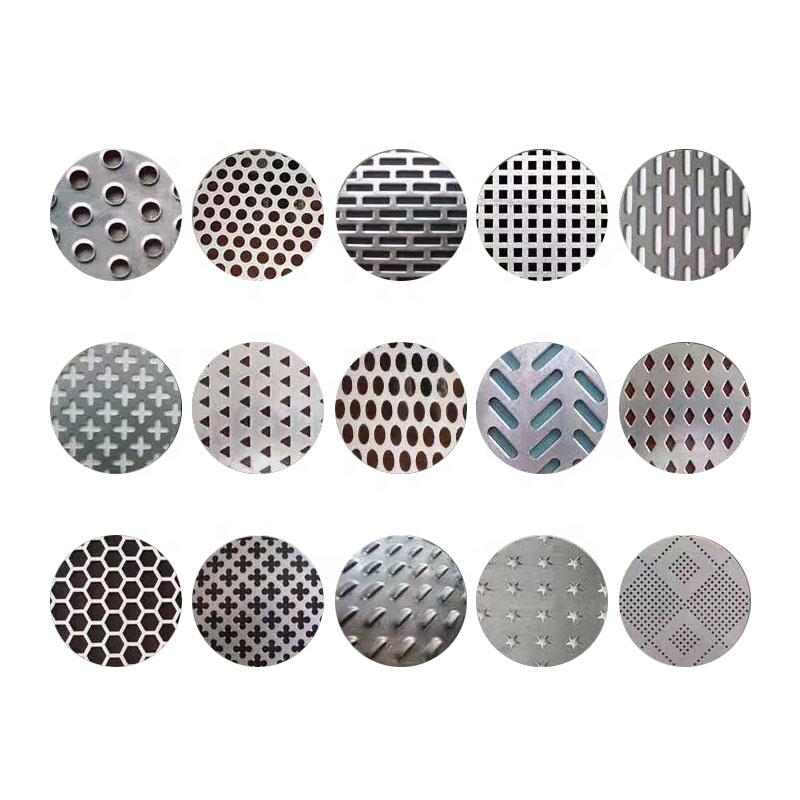

The 3D galvanized steel perforated metal sheet is available in a wide range of materials and dimensions, ensuring flexibility for various applications:

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers. |

| Thickness | Up to 18 mm. |

| Width | Up to 2,000 mm; coil width up to 1,600 mm for specific perforation types. |

| Length | Up to 6,000 mm. |

| Standard Operations | Single straightening, cutting to size, and pallet packing. |

| Additional Operations | Bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, and oil cleaning. |

Customization options are available upon consultation, with specific restrictions on thickness, width, and the need for unperforated technological margins for certain perforation types.

Applications Across Industries

The versatility of the 3D galvanized steel perforated metal sheet makes it a critical component in numerous sectors:

- Chemical Machinery: Used for filtration and separation processes in industrial equipment.

- Pharmaceutical Equipment: Ensures precision in drug manufacturing and sterilization systems.

- Food and Beverage Machines: Ideal for hygienic and durable components in processing machinery.

- Refrigeration Equipment: Enhances airflow and heat exchange in central air conditioning systems.

- Acoustic Applications: Integrated into silencing equipment and speaker enclosures for noise reduction.

- Construction and Architecture: Utilized in fencing, decorative panels, and structural supports.

The product's ability to balance strength, durability, and aesthetic appeal positions it as a preferred choice for both functional and design-oriented applications.

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd

Founded in 2005, AnPing Zhongtai Expanded Metal Mesh Co., Ltd has established itself as a leading manufacturer of perforated metal solutions. Located in Anping County, Hebei Province, the company leverages advanced production lines and a skilled workforce to deliver high-quality products tailored to global markets.

Key strengths of the company include:

- State-of-the-Art Technology: The use of automated cutting systems and KASRY Nesting programming ensures precision and efficiency.

- Comprehensive Services: From raw material selection to post-processing, the company offers end-to-end solutions.

- Commitment to Quality: Adherence to international standards and continuous improvement in manufacturing processes.

The company's dedication to innovation and customer satisfaction has earned it a reputation for reliability and excellence in the industry.

Industry Standards and Compliance

The 3D galvanized steel perforated metal sheet is designed to meet rigorous industry standards. While specific certifications are not detailed in the context, the company's alignment with global manufacturing practices reflects its commitment to quality. The National Institute of Standards and Technology (NIST), a U.S. government agency, plays a pivotal role in developing measurement standards that underpin industrial advancements. Although the product itself is not explicitly referenced in NIST publications, the principles of precision and reliability emphasized by NIST align with the company's operational ethos.

As noted by NIST, "Precision measurements are the foundation of technological innovation, ensuring that products meet the demands of modern industries" (NIST, 2025).

Conclusion

The 3D galvanized steel perforated metal sheet exemplifies the synergy between advanced engineering and practical application. With its robust construction, customizable features, and wide-ranging applications, it addresses the evolving needs of industries worldwide. AnPing Zhongtai Expanded Metal Mesh Co., Ltd continues to drive innovation, ensuring that its products remain at the forefront of industrial material solutions.

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.