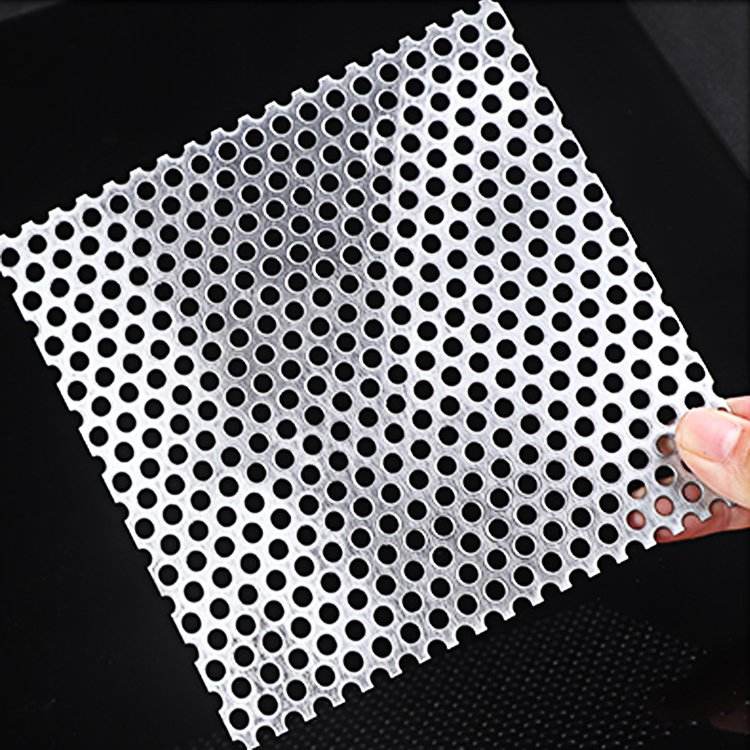

Perforated metal sheets have long been a cornerstone of industrial manufacturing, offering a unique blend of durability, functionality, and aesthetic appeal. Among the many options available, the 3D galvanized steel perforated metal sheet stands out as a cutting-edge solution designed to meet the evolving demands of diverse sectors. This article explores the product's advanced features, technical specifications, real-world applications, and the expertise of its manufacturer, AnPing Zhongtai Expanded Metal Mesh Co., Ltd.

Understanding the Structure and Production Process

The 3D galvanized steel perforated metal sheet is engineered with a sophisticated hole structure that ensures optimal performance. During production, the sheet undergoes three critical zones:

- Zone of Dents: This area forms the initial indentation, creating the foundation for the perforation pattern.

- Cutting Zone: Precision cutting tools shape the holes, ensuring uniformity and accuracy.

- Extraction Area: The material is carefully removed to create the final perforated design.

Typical sheets are produced with unperforated margins along the transverse and longitudinal edges. However, the company offers customization options, including full perforation fields or designs based on customer specifications. This flexibility allows industries to tailor the product to their unique requirements. Additionally, all sheets are straightened post-perforation, and further processing services such as bending, welding, and powder coating are available to create ready-made components.

Technical Specifications: Precision and Versatility

The 3D galvanized steel perforated metal sheet is available in a wide range of materials and dimensions, making it suitable for various applications. Key technical parameters include:

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers |

| Format | Thickness: Up to 18 mm | Width: Up to 2,000 mm | Length: Up to 6,000 mm | Coil Width (for coils): Up to 1,600 mm |

| Standard Operations | Single straightening, cutting to size, and pallet packing |

| Additional Operations | Bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, and oil cleaning |

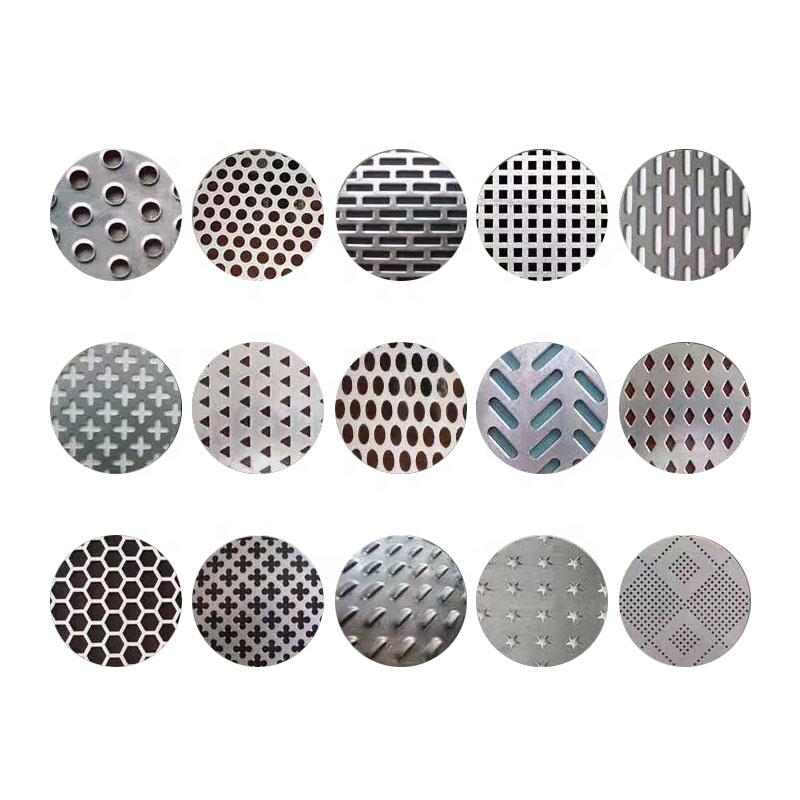

The product's adaptability is further enhanced by its ability to accommodate specialized perforation patterns. For instance, certain designs may require unperforated technological margins or restrictions on thickness and width. This level of customization ensures that the sheet meets the exacting standards of industries such as chemical machinery, pharmaceuticals, and food processing.

Applications Across Industries

The 3D galvanized steel perforated metal sheet is a versatile material that finds applications in numerous sectors. Its robust construction and precise perforation make it ideal for:

- Chemical Machinery: Used in filtration systems and containment structures due to its resistance to corrosion and wear.

- Pharmaceutical Equipment: Ensures hygiene and durability in environments requiring strict cleanliness standards.

- Food and Beverage Machines: Provides a safe, easy-to-clean surface for food processing equipment.

- Refrigeration Equipment: Enhances airflow and insulation in central air conditioning systems.

- Acoustic Applications: Effective in silencing equipment and speaker enclosures, where sound absorption is critical.

According to the National Institute of Standards and Technology (NIST), materials like perforated metal sheets play a vital role in advancing manufacturing standards. NIST's research on material durability and precision engineering underscores the importance of such products in ensuring industrial efficiency and safety (NIST, 2025). This aligns with the 3D galvanized steel perforated metal sheet's ability to meet rigorous industry requirements.

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd

Manufactured by AnPing Zhongtai Expanded Metal Mesh Co., Ltd, this product benefits from decades of expertise in metal processing. The company specializes in producing high-quality perforated and expanded metal products, serving clients across global markets. Their state-of-the-art production line, equipped with advanced cutting and perforation technologies, ensures precision and consistency in every batch.

AnPing Zhongtai's commitment to innovation is evident in their use of the KASRY Nesting programming system, which streamlines the production process. This software, integrated with AutoCAD, allows for efficient design and programming, reducing waste and improving operational efficiency (Product Page). Their ability to customize solutions, from standard perforation patterns to full-scale industrial applications, positions them as a trusted partner for manufacturers worldwide.

Why Choose 3D Galvanized Steel Perforated Metal Sheets?

The 3D galvanized steel perforated metal sheet offers several advantages that make it a preferred choice for industrial applications:

- Durability: Galvanization provides a protective zinc coating, enhancing resistance to rust and corrosion.

- Customization: The product can be tailored to specific dimensions, hole patterns, and surface treatments.

- Functional Design: The 3D structure allows for improved airflow, light transmission, and structural integrity.

- Cost-Effectiveness: By offering pre-processed components, the company reduces the need for additional manufacturing steps.

These features make the product particularly valuable in industries where efficiency and longevity are critical. For example, in filtration equipment, the sheet's precise hole patterns ensure optimal particle separation, while its durability reduces maintenance costs. In acoustic applications, the 3D structure enhances sound absorption, making it ideal for noise control in industrial settings.

Conclusion: A Reliable Solution for Modern Manufacturing

The 3D galvanized steel perforated metal sheet exemplifies the intersection of innovation and practicality in industrial manufacturing. With its advanced production process, versatile technical specifications, and wide-ranging applications, it addresses the needs of diverse sectors. Backed by the expertise of AnPing Zhongtai Expanded Metal Mesh Co., Ltd, this product is a testament to the company's commitment to quality and customer satisfaction.

For more information about the product or to explore customization options, visit the official product page or contact AnPing Zhongtai Expanded Metal Mesh Co., Ltd directly.

References

National Institute of Standards and Technology (NIST). (2025). Advancing Manufacturing Standards Through Material Innovation. Retrieved from https://www.nist.gov

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.