Introduction

The 3D Galvanized Steel Perforated Metal Sheet represents a cutting-edge solution in the realm of industrial and architectural materials. Designed for durability, versatility, and precision, this product is engineered to meet the demands of diverse industries. This article delves into the product's features, advantages, technical specifications, applications, and the company behind it, AnPing Zhongtai Expanded Metal Mesh Co., Ltd. By exploring its unique attributes and real-world utility, we aim to provide a comprehensive understanding of why this perforated metal sheet is a preferred choice for professionals worldwide.

Product Features and Advantages

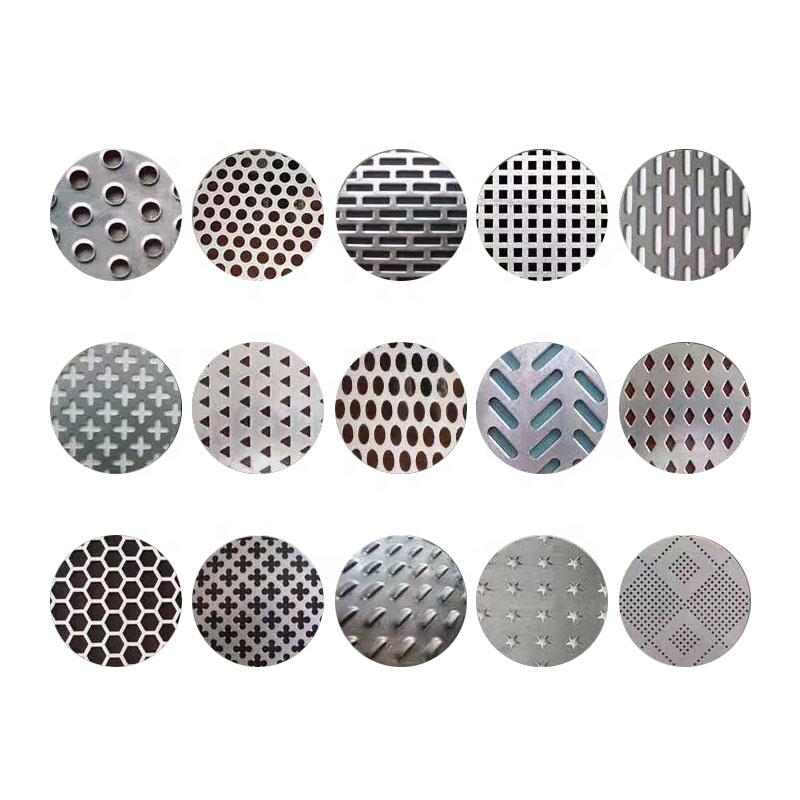

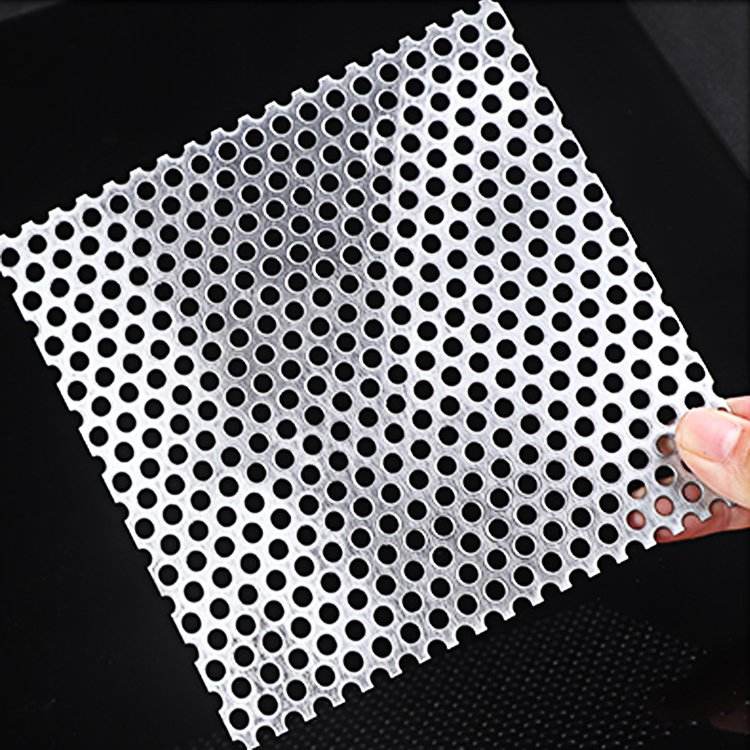

The 3D Galvanized Steel Perforated Metal Sheet is distinguished by its intricate design and robust construction. The perforation process involves three distinct zones: the dent zone, cutting zone, and extraction area. These zones ensure a precise and consistent hole structure, enhancing the sheet's structural integrity and functional performance. The product is available in various materials, including ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, and rubbers, catering to a wide range of industrial needs.

One of the key advantages of this perforated metal sheet is its adaptability. Standard sheets come with unperforated transverse and longitudinal margins, while custom options allow for full perforation fields or specific designs based on customer drawings. This flexibility ensures that the product can be tailored to meet unique project requirements. Additionally, the sheets are straightened after perforation, and further processing services such as bending, rolling, and powder coating are available, providing customers with ready-made components that reduce the need for additional manufacturing steps.

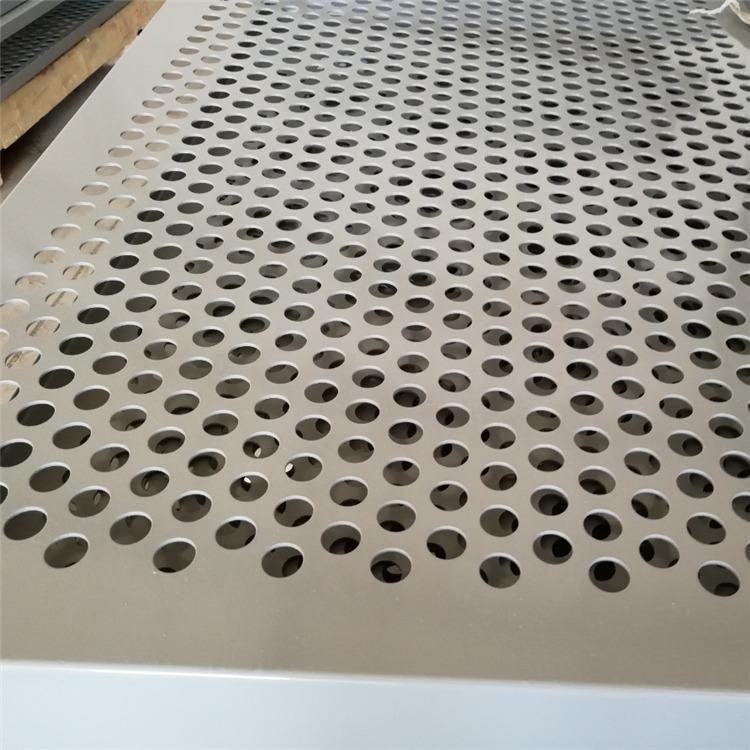

The 3D Galvanized Steel Perforated Metal Sheet also excels in durability and corrosion resistance. The galvanization process coats the steel with a protective layer of zinc, significantly enhancing its lifespan, especially in harsh environments. This makes it an ideal choice for applications in industries such as chemical machinery, pharmaceutical equipment, and food and beverage processing, where exposure to moisture and chemicals is common.

Technical Specifications

The 3D Galvanized Steel Perforated Metal Sheet is manufactured to meet stringent technical standards, ensuring optimal performance in various applications. The following table outlines the product's key specifications:

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers |

| Format | Thickness up to 18 mm, width up to 2,000 mm, length up to 6,000 mm. Coil width up to 1,600 mm for some assortments |

| Standard Operations | Single straightening, cutting to size, packing on pallets |

| Additional Operations | Bending, rolling, pressing, trapezoidal, framing, welding, powder coating, wiping/cleaning with oil |

These specifications highlight the product's versatility and ability to accommodate both standard and custom requirements. The thickness and width limitations, along with the need for unperforated technological margins in certain cases, underscore the importance of consulting with the manufacturer to ensure optimal results.

Applications in Diverse Industries

The 3D Galvanized Steel Perforated Metal Sheet is a versatile material with applications across multiple industries. Its unique properties make it suitable for use in chemical machinery, pharmaceutical equipment, food and beverage machines, cigarette machines, harvesters, dry-cleaning machines, ironing tables, silencing equipment, refrigeration equipment (including central air conditioning), speakers, crafts, papermaking, hydraulic fittings, and filtration equipment. This wide range of applications demonstrates the product's adaptability and reliability in demanding environments.

In the chemical machinery sector, the sheet's corrosion resistance and durability ensure long-term performance in environments with exposure to harsh chemicals. In pharmaceutical equipment, the material's ability to maintain structural integrity and hygiene makes it ideal for use in manufacturing and packaging processes. For food and beverage machines, the perforated design allows for efficient filtration and drainage, while the galvanized coating prevents rust and contamination.

The 3D Galvanized Steel Perforated Metal Sheet also finds applications in silencing equipment and refrigeration systems, where its acoustic and thermal properties contribute to improved performance. In filtration equipment, the precise hole structure ensures effective separation of materials, while the durability of the sheet ensures longevity even under continuous use.

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd

Founded in AnPing County, Hebei Province, China, AnPing Zhongtai Expanded Metal Mesh Co., Ltd is a leading manufacturer of perforated metal sheets and related products. With decades of experience in the industry, the company has established itself as a reliable supplier of high-quality materials for industrial and architectural applications. The company's commitment to innovation, precision, and customer satisfaction has earned it a reputation for excellence in the global market.

AnPing Zhongtai's production capabilities are supported by advanced manufacturing technologies and a dedicated team of engineers and technicians. The company's 3D Galvanized Steel Perforated Metal Sheet is a testament to its expertise in developing products that meet the evolving needs of its customers. By offering a wide range of materials, custom design options, and value-added services, the company ensures that its products are tailored to the specific requirements of each project.

The company's focus on quality control is evident in its rigorous testing processes and adherence to international standards. This commitment to quality is further reinforced by the use of high-grade materials and state-of-the-art production equipment, ensuring that every product meets the highest standards of performance and reliability.

Expert Insights and Industry Standards

The 3D Galvanized Steel Perforated Metal Sheet aligns with industry standards for material performance and safety. According to the National Institute of Standards and Technology (NIST), precision in material manufacturing is critical for ensuring the reliability and longevity of industrial components. NIST's research on material properties and measurement standards highlights the importance of accurate perforation techniques and corrosion-resistant coatings, both of which are integral to the 3D Galvanized Steel Perforated Metal Sheet.

As noted in NIST's publications, the development of advanced materials with enhanced durability and functionality is a key focus area for modern industries. The 3D Galvanized Steel Perforated Metal Sheet exemplifies this trend, offering a solution that combines structural integrity with adaptability to diverse applications. By adhering to these standards, AnPing Zhongtai Expanded Metal Mesh Co., Ltd ensures that its products are not only competitive but also compliant with global industry benchmarks.

Conclusion

The 3D Galvanized Steel Perforated Metal Sheet is a versatile and durable material that caters to a wide range of industrial and architectural needs. Its precise perforation process, customizable design options, and corrosion-resistant properties make it an ideal choice for applications in chemical machinery, pharmaceutical equipment, food and beverage processing, and more. Backed by the expertise of AnPing Zhongtai Expanded Metal Mesh Co., Ltd, this product exemplifies the intersection of innovation and quality in material manufacturing.

As industries continue to evolve, the demand for high-performance materials like the 3D Galvanized Steel Perforated Metal Sheet will only grow. With its ability to meet both standard and custom requirements, this product is poised to remain a cornerstone in the development of advanced manufacturing solutions. For more information, visit the product page or AnPing Zhongtai Expanded Metal Mesh Co., Ltd's official website.

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.