Perforated metal sheets have become a cornerstone of modern industrial applications, offering a blend of durability, functionality, and aesthetic appeal. Among these, the 3D galvanized steel perforated metal sheet stands out as a versatile solution for fencing and beyond. This article delves into the product's features, technical specifications, applications, and the company behind it, AnPing Zhongtai Expanded Metal Mesh Co., Ltd.

Understanding the Structure of the Perforated Metal Sheet

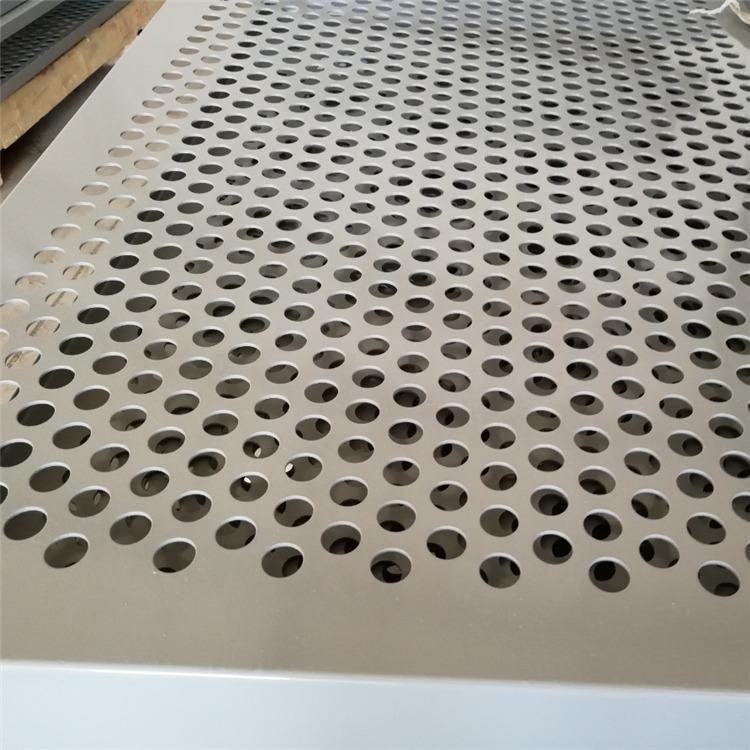

The 3D galvanized steel perforated metal sheet is engineered with a unique hole structure that enhances its performance. The manufacturing process involves three critical zones:

- Zone of dents: This area forms the initial indentation during the perforation process.

- Cutting zone: Here, the material is precisely cut to create the holes.

- Extraction area: This section facilitates the removal of the cut material, ensuring clean and uniform holes.

The sheet also features unperforated transverse and longitudinal margins as a standard, providing structural integrity. Custom designs, including full perforation fields, are available upon consultation, allowing for tailored solutions to specific requirements.

Image 1: 3D galvanized steel perforated metal sheet with intricate hole patterns.

Technical Specifications and Material Options

The 3D galvanized steel perforated metal sheet is available in a wide range of materials and dimensions, making it suitable for diverse applications. Key technical parameters include:

| Parameter | Details |

|---|---|

| Material | Ordinary steel, abrasion-resistant, heat-resistant, stainless, acid-resistant, aluminum, copper, brass, bronze, plastics, rubbers. |

| Format | Thickness: Up to 18 mm; Width: Up to 2,000 mm; Length: Up to 6,000 mm. Coils can be perforated with a width up to 1,600 mm. |

| Standard Operations | Single straightening, cutting to size, and packing on pallets. |

| Additional Operations | Bending, rolling, pressing, trapezoidal shaping, framing, welding, powder coating, and oil cleaning. |

These specifications highlight the product's adaptability to different industrial needs. The ability to customize the sheet's dimensions and finish ensures it meets the unique demands of various sectors.

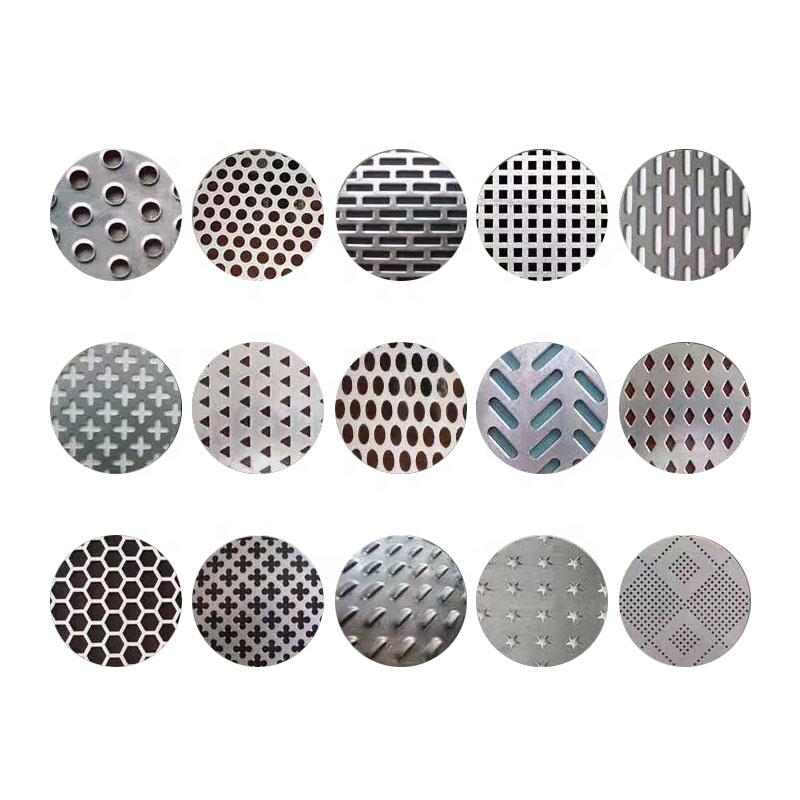

Image 2: Close-up view of the perforated surface, showcasing the precision of the hole structure.

Applications Across Industries

The 3D galvanized steel perforated metal sheet is a versatile material with applications spanning multiple industries. Its use cases include:

- Chemical machinery: Provides durable, corrosion-resistant components for processing equipment.

- Pharmaceutical equipment: Ensures hygiene and compliance with stringent industry standards.

- Food and beverage machines: Offers easy-to-clean surfaces that meet food safety regulations.

- Filtering equipment: Efficiently separates particles and liquids in industrial processes.

- Architectural design: Adds aesthetic value while maintaining structural integrity in fencing and partitions.

Additionally, the sheet is utilized in fencing applications, where its strength and durability make it ideal for both residential and commercial settings. The galvanized coating enhances resistance to rust and corrosion, ensuring longevity even in harsh environments.

Image 3: Installation of the perforated metal sheet in a fencing project, demonstrating its practicality and aesthetics.

Company Background: AnPing Zhongtai Expanded Metal Mesh Co., Ltd.

Founded in AnPing Zhongtai Expanded Metal Mesh Co., Ltd, the company has established itself as a leader in the production of perforated metal sheets. With a commitment to quality and innovation, the company offers a wide range of products tailored to meet the needs of global markets. Their expertise in manufacturing processes ensures that each product adheres to the highest standards of precision and durability.

As highlighted by the National Institute of Standards and Technology (NIST), the importance of standardized manufacturing processes cannot be overstated. NIST's research underscores the role of precision engineering in enhancing product performance and safety [1]. AnPing Zhongtai's adherence to such principles positions it as a reliable partner for industries seeking high-quality materials.

Advantages of the 3D Galvanized Steel Perforated Metal Sheet

The 3D galvanized steel perforated metal sheet offers several advantages that make it a preferred choice in various applications:

- Durability: The galvanized coating provides exceptional resistance to corrosion, making it suitable for outdoor and industrial environments.

- Customization: The ability to create custom hole patterns and dimensions allows for tailored solutions to specific requirements.

- Strength: The 3D structure enhances the sheet's load-bearing capacity, making it ideal for fencing and structural applications.

- Cost-effectiveness: The product's longevity and low maintenance requirements reduce long-term costs for users.

Conclusion

The 3D galvanized steel perforated metal sheet is a testament to the advancements in metalworking technology. Its unique structure, combined with a wide range of materials and customization options, makes it a versatile solution for various industries. AnPing Zhongtai Expanded Metal Mesh Co., Ltd. continues to innovate, ensuring that their products meet the evolving needs of the market. As NIST emphasizes the importance of standardized manufacturing, the company's commitment to quality and precision ensures that their products remain a trusted choice for global applications.

References:

[1] National Institute of Standards and Technology (NIST). (n.d.). Standards and Measurements. https://www.nist.gov/

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

-

Comprehensive Guide to Twisted Bar Grating – Uses, Benefits & Future Trends

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.