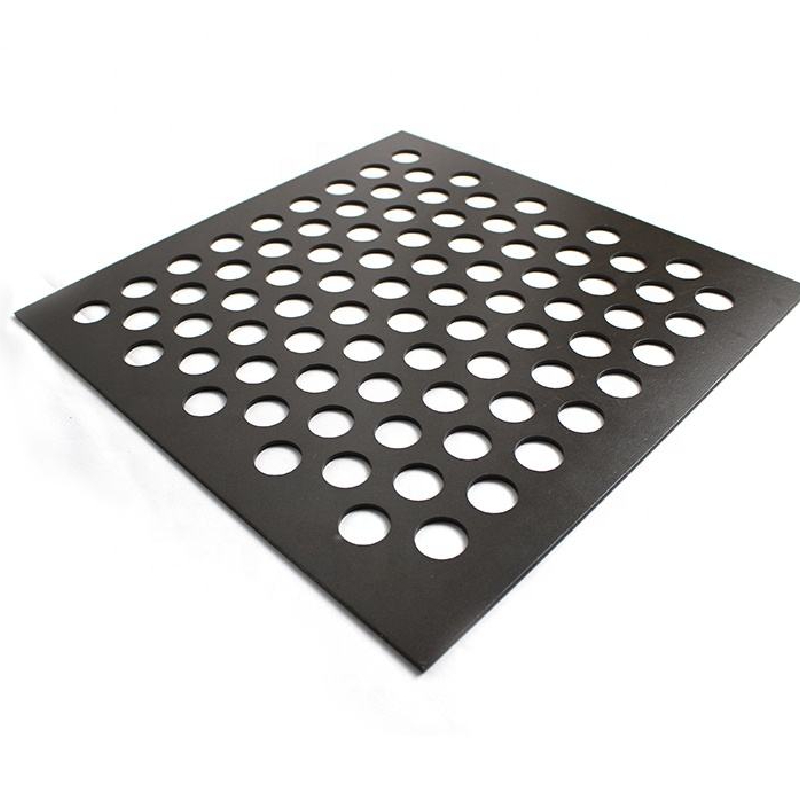

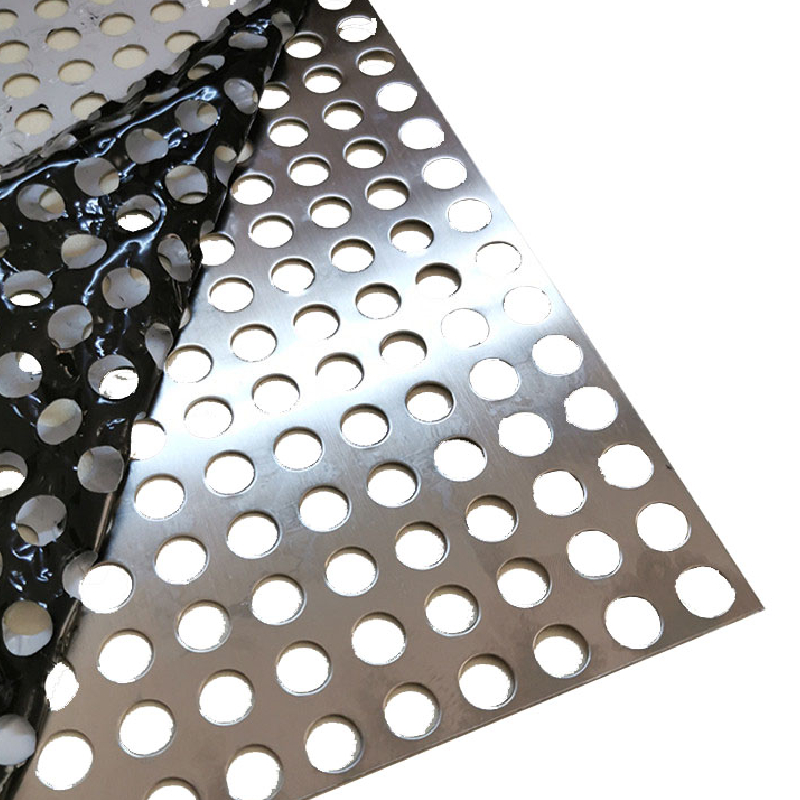

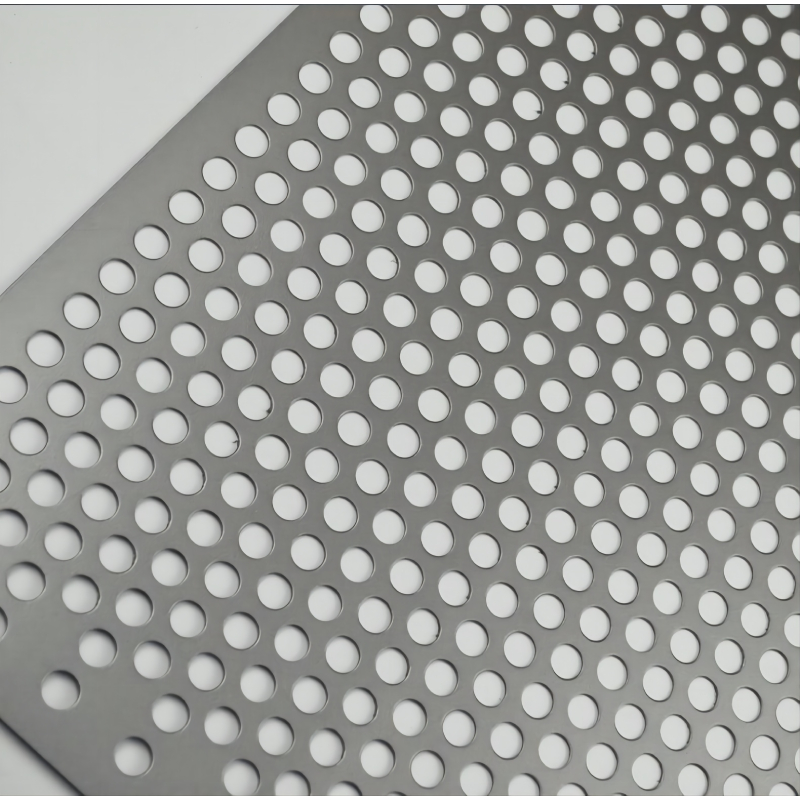

Field Notes on [Round Perforated Steel Sheet] in Real Projects

I’ve walked more factory floors than I can count, and this product keeps showing up—in HVAC plenums, brewery guards, even minimalist facades. The typical sheets are produced with unperforated transverse and longitudinal margins, which sounds dull, but actually it’s what installers love: cleaner clamping, easier alignment, less edge distortion.

What’s trending (and why it matters)

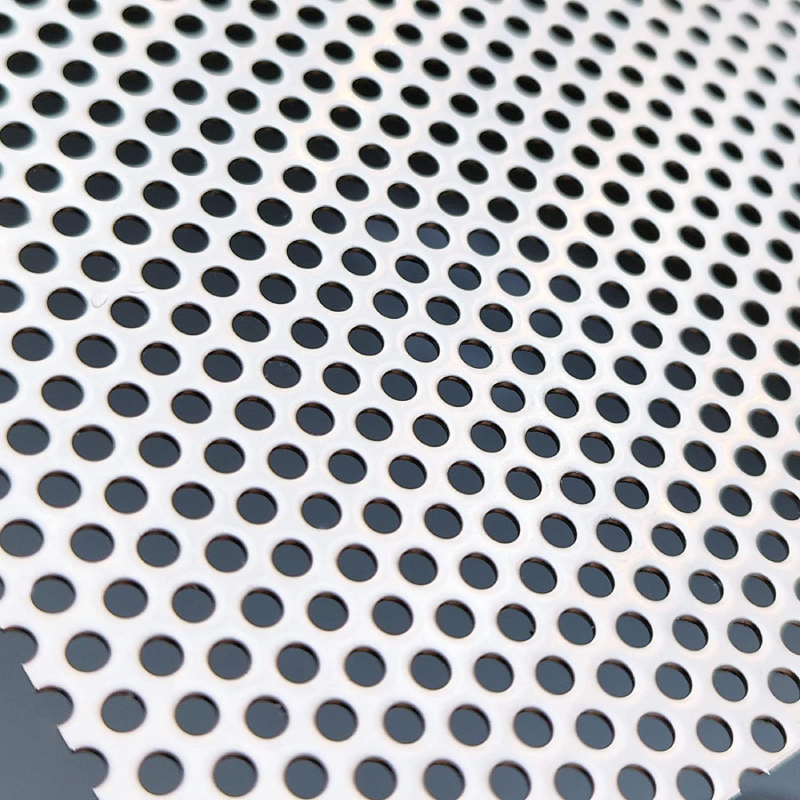

Two clear shifts: tighter hole tolerances for acoustic predictability, and coatings that shrug off coastal air. Many customers say they’ll pay a bit more for consistent open area because real-world airflow and decibel ratings depend on it. To be honest, I would too.

Quick specification snapshot

| Parameter | Typical Range (≈ / real use may vary) |

|---|---|

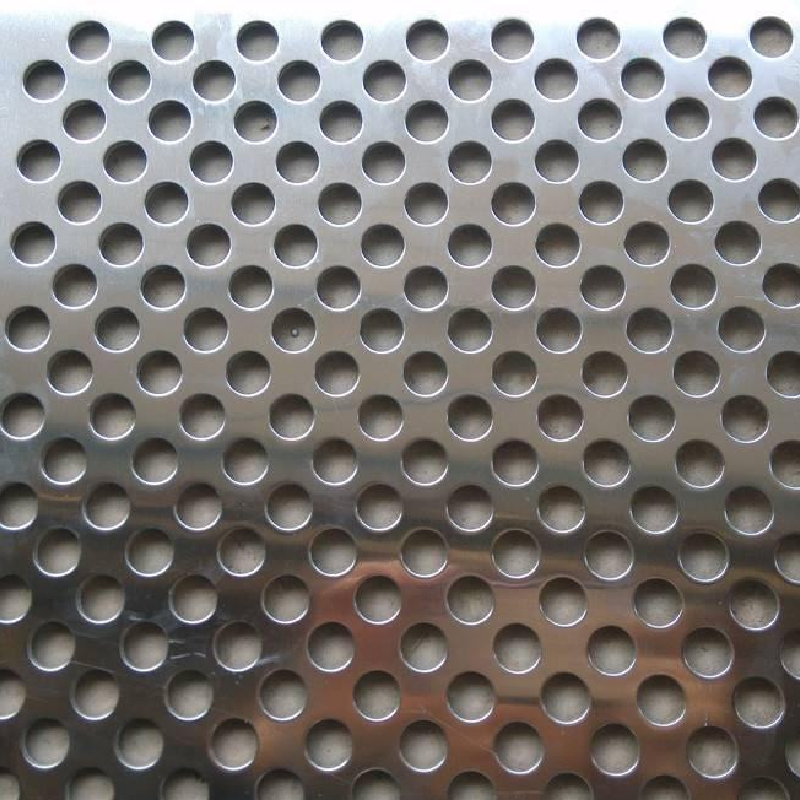

| Materials | Galvanized steel (ASTM A653, EN 10346), SS304/316 (ASTM A240), mild steel Q235 |

| Thickness | 0.5–3.0 mm |

| Hole diameter | 1–20 mm, round; pitch 1.5×D–3×D |

| Open area | 20–60% |

| Sheet size | 1000×2000, 1220×2440, 1500×3000 mm; custom |

| Margins | Unperforated transverse & longitudinal (standard) |

| Finishes | HDG (ISO 1461), powder coat (RAL), oil, pickled, PVDF |

| Tolerances | Hole roundness ±0.15 mm; flatness ≤3 mm/m |

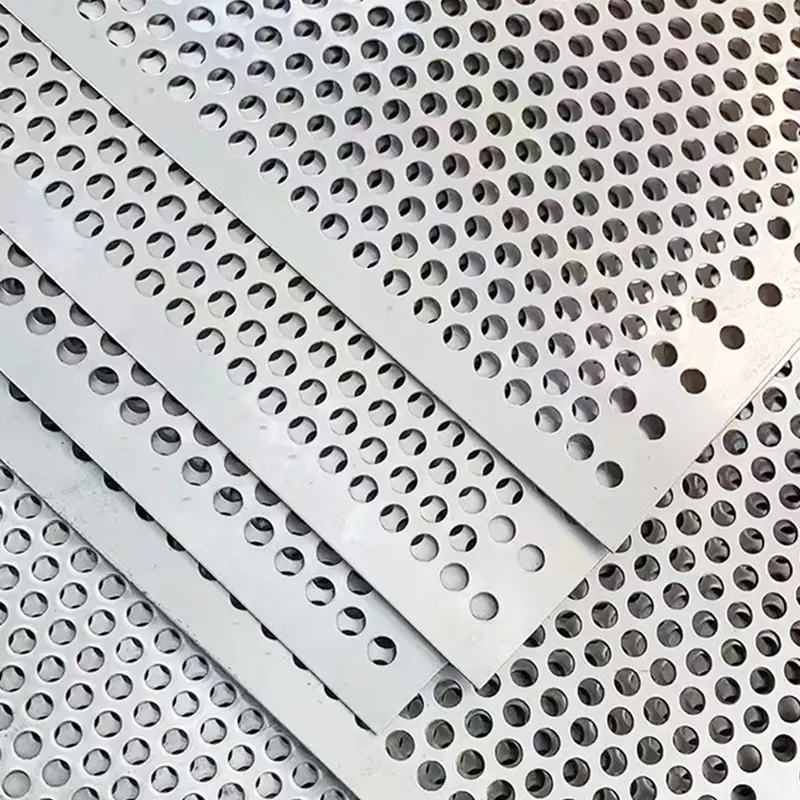

Process, testing, and service life

Materials are decoiled, leveled, then CNC-punched or turret-pressed; deburred, flattened, and coated. QC uses optical measurement for pitch and open area, Rockwell hardness spot checks, and salt-spray (ASTM B117) when coated. In normal urban conditions, coated Round Perforated Steel Sheet lasts ≈10–25 years; stainless often exceeds that, frankly depending on chloride exposure.

Where it’s used

- HVAC plenums and silencers; - Machine guards and safety barriers; - Architectural sunscreens; - Food & beverage screens (SS316); - Agricultural drying trays; - Filtration pre-screens. One facility manager told me, “airflow hit the spec on the first try,” which is rarer than you’d think.

Advantages that show up on-site

Consistent open area improves acoustic models; margins speed installation; galvanized options balance cost and lifespan. Test notes: SS304 tensile ≈520–720 MPa; coating endurance ≥240 h salt-spray for quality powder coats.

Vendor comparison (field view)

| Vendor | Lead time | Certs | Customization | Notes |

|---|---|---|---|---|

| ZT Wire Mesh (Anping, Hebei; No. 12, Jingwu Rd.) | 7–15 days (stock patterns) | ISO 9001; material MTCs | Hole map, margins, coatings | Tight tolerances; fair pricing |

| Vendor B | 15–25 days | ISO 9001 | Standard sets | Stable but fewer options |

| Vendor C | 10–20 days | — | Limited | Budget-first approach |

Customization playbook

Specify diameter/pitch grid, margin widths, coil vs. sheet, bending radius, and finish. For acoustics, many engineers request 2–3 mm holes at ≈40% open area; for guards, 6–10 mm at ≈30%. I guess it’s common sense: balance airflow, strength, and finger-safe design.

Case study: quieter packaging hall

A food packer swapped plain guards for Round Perforated Steel Sheet (2.5 mm holes, 38% OA, powder coat). Noise at operator stations dropped ≈4–6 dB, airflow stayed within ±5% of the model, and cleaning got faster. Small change, big morale lift, surprisingly.

Certifications and standards (the fine print)

Look for ISO 9001 factory systems, ASTM A653/A240 material grades, EN 10346 for coated steel, ISO 1461 for HDG, and ASTM B117 corrosion testing. It’s not glamorous, but it’s what keeps projects on spec.

- ASTM A653/A653M: Standard Spec for Steel Sheet, Zinc-Coated (Galvanized).

- ASTM A240/A240M: Stainless Steel Plate, Sheet, and Strip.

- EN 10346: Continuously hot-dip coated steel flat products.

- ISO 1461: Hot dip galvanized coatings on fabricated iron and steel articles.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- ISO 9001: Quality management systems — Requirements.

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.