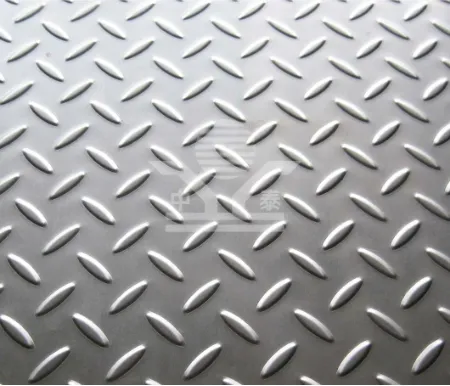

Punching Hole Wire Mesh — Insider Guide to Buying Perforated Sheet Metal

If you’re hunting for Perforated Metal Sheet For Sale and don’t want guesswork, here’s the straight talk. I’ve toured plants in Hebei and the Yangtze Delta, and the real differentiator isn’t just hole patterns—it’s process control and post-treatment. The product we’re looking at today is the “Punching Hole Wire Mesh China Suppliers Perforated Sheet Metal,” made in Anping (the wire mesh capital), with surface treatment galvanized and a surprisingly “miniature” weight option for lightweight projects.

What’s trending (and why it matters)

Demand is shifting from basic guard panels to architectural façades, acoustic control, and precision filtration. Actually, more buyers ask for tighter tolerances and coated finishes that survive coastal air. Turret punching and fiber-laser perforation are both used—turret for cost efficiency on standard patterns, laser for odd geometries and quick protos. Sustainability? Galvanized steel remains the workhorse, but designers increasingly spec aluminum and SS316 where life-cycle costs beat upfront price.

Core specs at a glance

| Product Name | Punching Hole Wire Mesh China Suppliers Perforated Sheet Metal |

| Materials | Galvanized steel (ASTM A653), SS304/SS316, Aluminum 1xxx/3xxx |

| Hole Types | Round, slotted, square, hex; open area ≈ 15–60% (real-world use may vary) |

| Thickness | 0.5–3.0 mm common; up to 6 mm on request |

| Hole Diameter & Pitch | φ0.8–20 mm; staggered or straight pattern per DIN 24041 tolerances |

| Sheet Size | 1000×2000 mm, 1220×2440 mm; custom sizes cut-to-length |

| Finish | Galvanized (pre/post), optional powder coating; burr ≤ 0.1 mm (typ.) |

| Service Life | ≈ 10–25 years, environment-dependent (coastal needs heavier coating) |

| Usage | Protection, aquaculture, water conservancy, civil & railway/road construction |

Many customers say the “miniature” weight variant hits that sweet spot for airflow plus stiffness. For what it’s worth, I’ve seen it hold up in gritty rail corridors where grit and vibration are unforgiving.

Process flow (how quality happens)

Materials: certified coils (galv/SS/Al) → decoiling & leveling → CNC turret punching or laser perf → stress-relief leveling → deburring → galvanizing or coating → final shear → QA.

Testing standards and typical targets: salt spray (ASTM B117) 240–480 h for galvanized; thickness per ASTM A653; hole/pitch tolerance per DIN 24041; flatness ≤ 2 mm/m; visual burr control; dimensional reports archived under ISO 9001. To be honest, the flatness step is where budget vendors cut corners—watch for wave or potato-chipping.

Where it’s used

Aquaculture screens, water conservancy inlets, plant guards, HVAC grilles, façade cladding, road/rail barricades, and filtration pre-screens. In fact, Perforated Metal Sheet For Sale is often specified as a lighter alternative to expanded metal when aesthetics and precise open area matter.

Vendor comparison (quick reality check)

| Vendor | MOQ | Lead Time | Customization | Certs | Price Level |

|---|---|---|---|---|---|

| ZT Wire Mesh (Anping, Hebei) | ≈ 50–100 sheets | 7–15 days | Hole pattern, thickness, coating, cut-to-size | ISO 9001 | Competitive |

| Local Fabricator | Low | 2–5 days (limited patterns) | Basic; fewer dies | Varies | Mid–High |

| Import Aggregator | High | 20–40 days | Wide catalog, slower changes | Mixed | Low–Mid |

Customization and real-world notes

You can tweak hole geometry for airflow vs. rigidity, request post-galvanizing after punching (better corrosion on edges), and specify powder topcoat for UV. For SS316 near seawater, I’d pick 1.5–2.0 mm thickness and 30–40% open area. It seems that Perforated Metal Sheet For Sale with staggered round holes still hits the best strength-to-cost ratio.

Mini case studies

- Southeast Asia aquaculture: galvanized round-hole panels, 480 h B117, service life ~8–12 yrs with routine rinse.

- Metro ventilation grilles: SS304, burr ≤0.05 mm, flatness ≤1.5 mm/m; vandal-resistant yet breathable.

- Water conservancy intake screens: slotted holes to control debris; post-galv improved edge protection.

Origin and contact

Manufactured in: No. 12, Jingwu Road, East District, Industrial Park, Anping County, Hengshui, Hebei, China. If you’re benchmarking Perforated Metal Sheet For Sale, ask for test reports (B117 hours, burr, flatness) and a few sample coupons—small step, big peace of mind.

Certifications & references

-

Steel Walkway Grating Prices Explained: Essential Insights for Industry and Infrastructure

NewsNov.24,2025

-

Comprehensive Guide to Steel Grating Price and Its Global Impact

NewsNov.24,2025

-

Understanding Heavy Duty Steel Grating Price: Global Insights & Industry Trends

NewsNov.23,2025

-

Essential Guide to Wire Mesh Grating: Uses, Benefits & Innovations

NewsNov.23,2025

-

Welded Steel Bar Grating: Durable Solutions for Industrial Walkways & Infrastructure

NewsNov.22,2025

-

Wedge Wire Drain Solutions: Durable, Efficient Water Filtration and Drainage

NewsNov.22,2025

Subscribe now!

Stay up to date with the latest on Fry Steeland industry news.